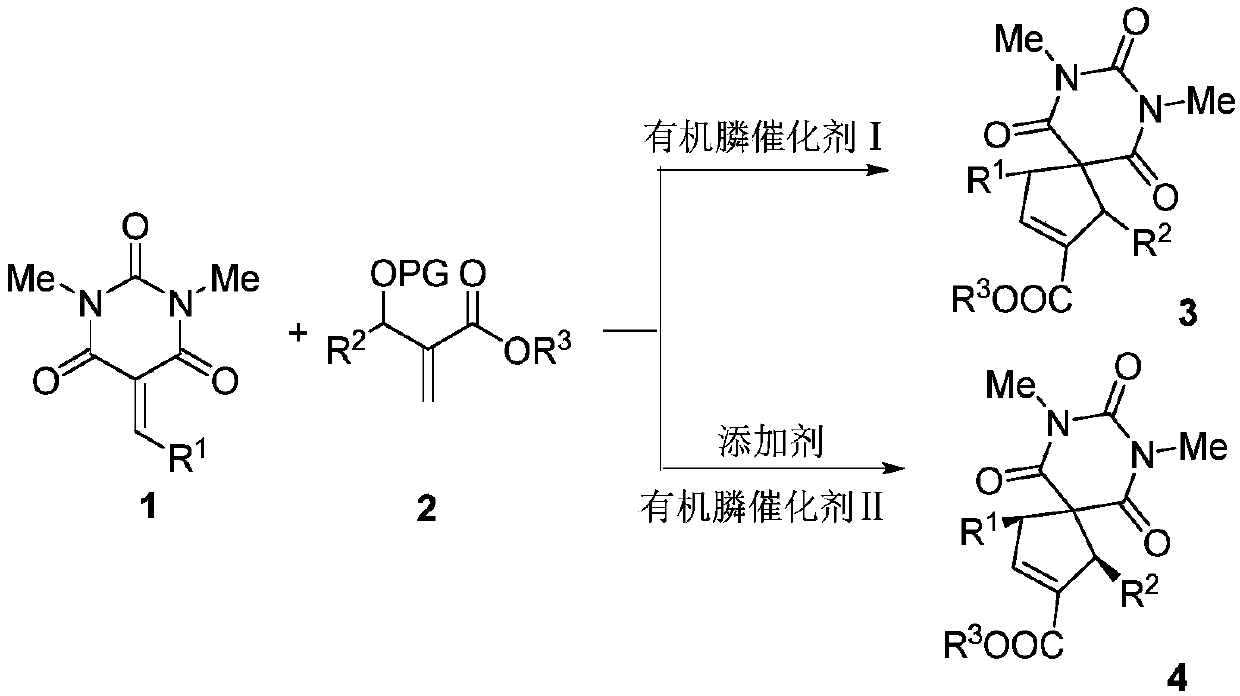

Barbituric acid-cyclopentene spiro compound and preparation method thereof

A technology of spiro compound and barbiturate is applied in the field of organic compound synthesis to achieve high stereoselectivity and enantioselectivity, increase diversity and expand applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

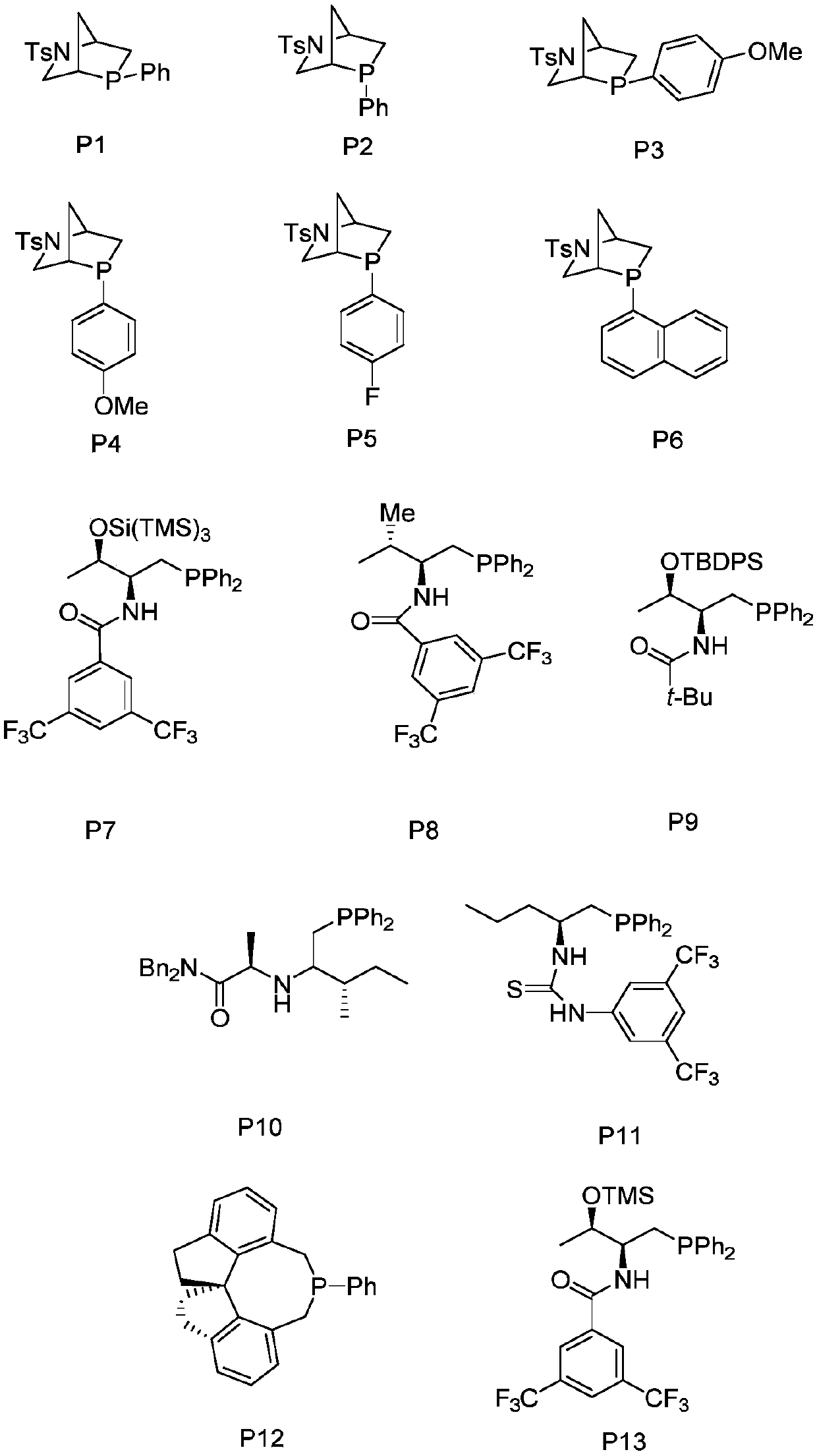

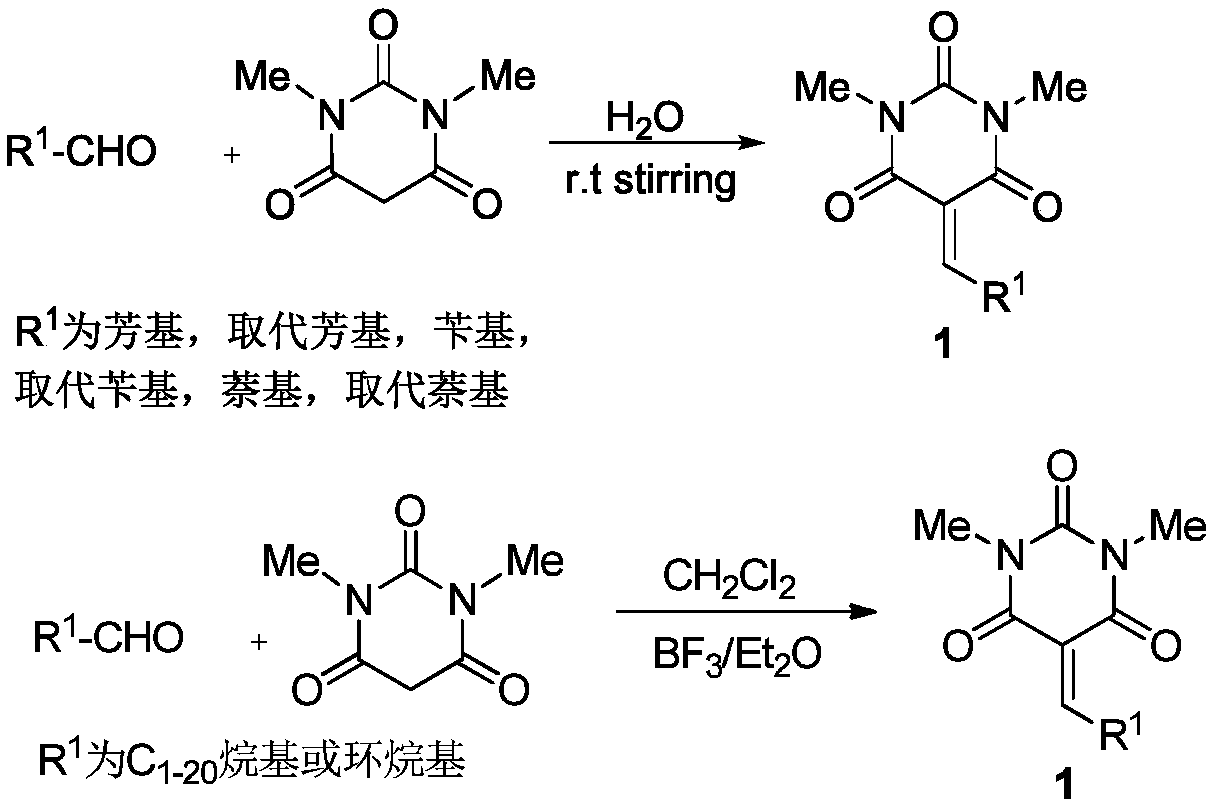

Method used

Image

Examples

Embodiment 1

[0031]

[0032]Put 0.0244g (0.100mmol) of compound 1a, 0.0350g (0.120mmol) of compound 2a and 3mL of 1,2-dichloroethane into a dry 15mL Shrek tube, add 0.020mmol of methyl diphenylphosphine and mix well Carry out a cycloaddition reaction. In the reaction system, the molar ratio of compound 1a to compound 2a is 1:1.2, methyldiphenylphosphine accounts for 20% of the molar percentage of compound 1a, stirred at 40°C for 24 hours, and concentrated through the column with a rotary evaporator (Ethyl acetate:petroleum ether=1:10, v / v), 23.4 mg of product 3aa was obtained, with a yield of 56%.

Embodiment 2

[0034]

[0035] Put 0.0244g (0.100mmol) of compound 1a, 0.0350g (0.120mmol) of compound 2a and 3mL of toluene into a dry 15mL Shrek tube, add 0.020mmol of methyl diphenylphosphine and mix well for cycloaddition reaction. In the reaction system, the molar ratio of compound 1a to compound 2a is 1:1.2, methyldiphenylphosphine accounts for 20% of the molar percentage of compound 1a, stirred at 40°C for 24 hours, and concentrated through the column with a rotary evaporator (Ethyl acetate:petroleum ether=1:10, v / v), 36.8 mg of product 3aa was obtained, with a yield of 89%.

[0036] It can be seen that the effect is very excellent when selecting toluene as the solvent.

Embodiment 3

[0038]

[0039] Put 0.0244g (0.100mmol) of compound 1a, 0.0350g (0.120mmol) of compound 2a and 3mL of toluene into a dry 15mL Shrek tube, add 0.020mmol of dimethylphenylphosphine and mix well for cycloaddition reaction. In this reaction system, the molar ratio of compound 1a to compound 2a is 1:1.2, dimethylphenylphosphine accounts for 20% of the molar percentage of compound 1a, stirred at 40°C for 24 hours, concentrated through the column with a rotary evaporator (Ethyl acetate:petroleum ether=1:10, v / v), 31.5 mg of product 3aa was obtained, with a yield of 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com