A kind of ionic liquid with adjustable polarity and its preparation method and application

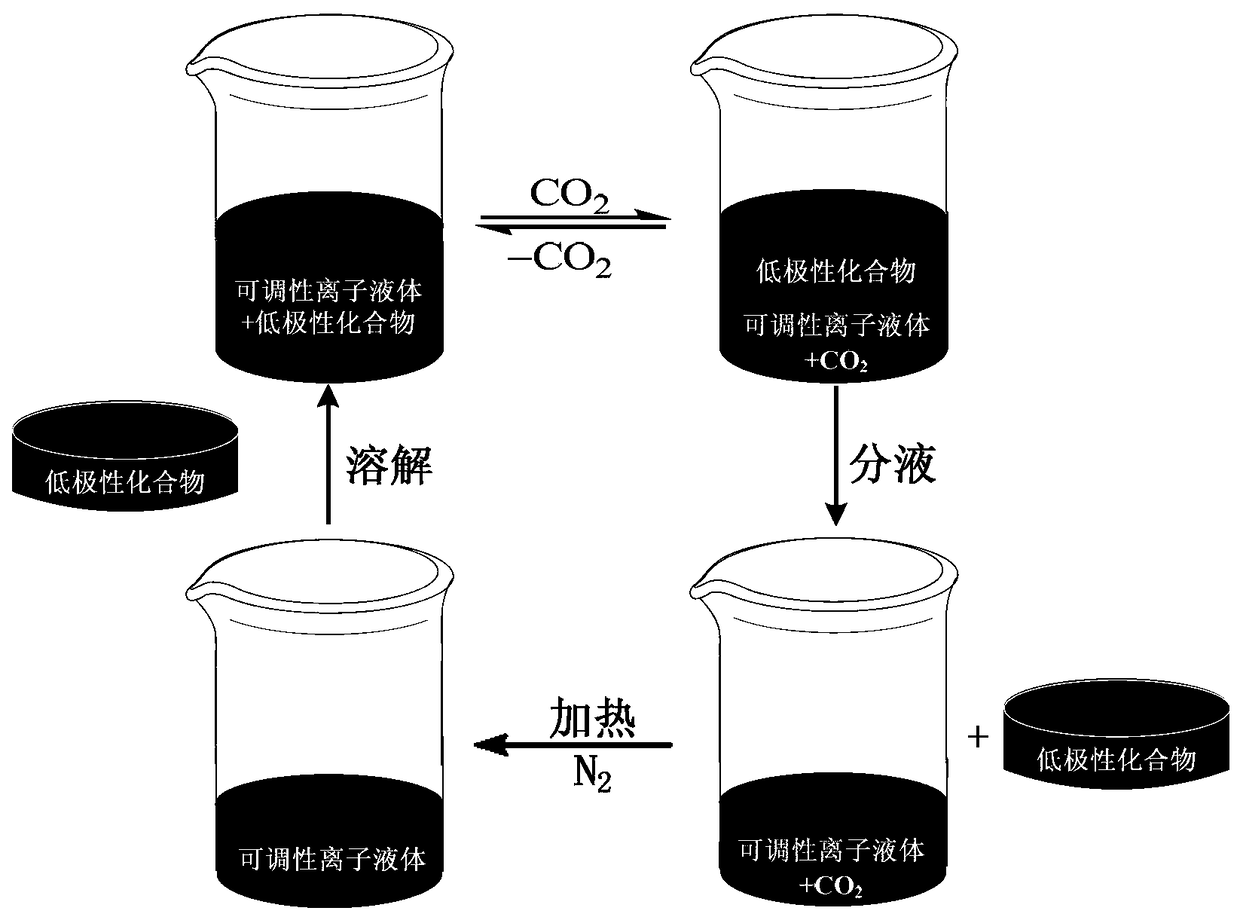

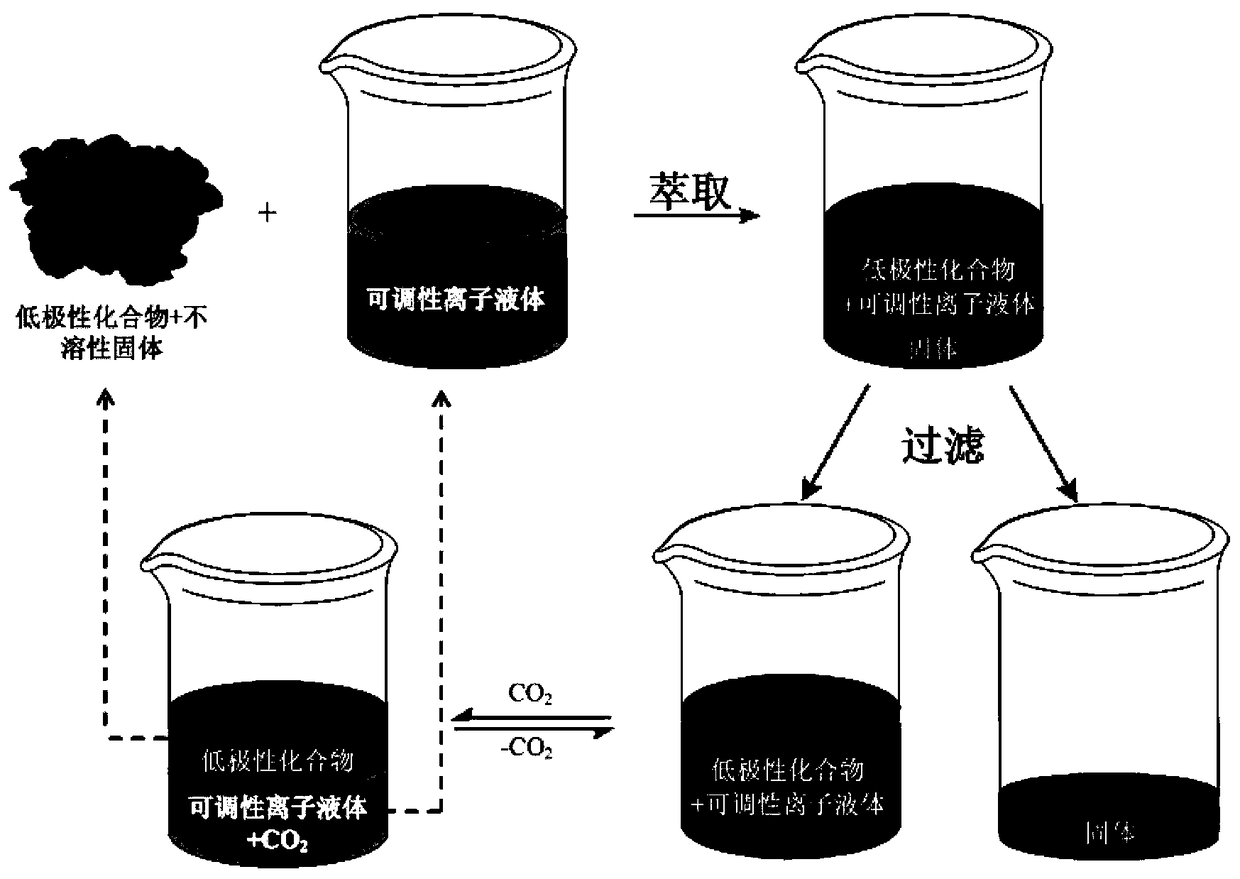

An ionic liquid, polar technology, applied in extraction purification/separation, organic chemistry, etc., can solve the problems of strong volatility and high viscosity of single-component polar adjustable solvents, achieve good economic benefits, good repeatability, synthesis The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The synthesis device of the ionic liquid is a three-necked flask equipped with a stirring paddle and a dropping funnel. Weigh a certain amount of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), add it into a three-necked flask and stir. Accurately weigh TFE according to the ratio of DBU to 2,2,2-trifluoroethanol (TFE) molar ratio of 1:1 and add it to the dropping funnel. Control the reaction temperature to 0°C, open the dropping funnel, and slowly drop TFE into the kettle. After the dropwise addition, continue to stir in the kettle for 0.5h. Afterwards, the solution was rotated and evaporated under reduced pressure at 30 °C for 2 h to remove excess TFE, and the polarity-tunable ionic liquid [DBUH + ][TFE - ]. The experimental raw materials did not require any drying treatment.

Embodiment 2

[0052] The synthesis device of the ionic liquid is a three-necked flask equipped with a stirring paddle and a dropping funnel. Weigh a certain amount of tetramethylguanidine (TMG), add it into a three-neck flask and stir. Accurately weigh TFE according to the ratio of TMG to 2,2,2-trifluoroethanol (TFE) molar ratio of 1:0.5 and add it to the dropping funnel. The reaction temperature was controlled at 5°C, the dropping funnel was opened, and TFE was slowly added dropwise into the kettle. After the dropwise addition, continue to stir in the kettle for 2h. Afterwards, the solution was rotary evaporated under reduced pressure at 50 °C for 3 h to remove excess TMG, and the polarity-tunable ionic liquid [TMGH + ][TFE - ]. The experimental raw materials did not require any drying treatment.

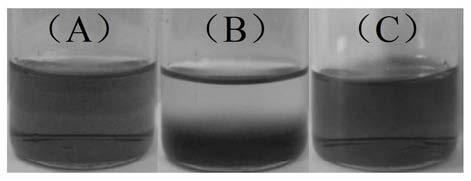

[0053] Carry out to the ionic liquid of embodiment 1, embodiment 2 1 H. 13 C NMR analysis is compared with DBU, TMG, TFE standard spectra, and the analysis data is recorded in the followi...

Embodiment 3

[0058] The synthesis device of the ionic liquid is a three-necked flask equipped with a stirring paddle and a dropping funnel. Weigh a certain amount of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), add it into a three-necked flask and stir. Accurately weigh TFP according to the ratio of DBU to 2,2,3,3-tetrafluoropropanol (TFP) molar ratio of 1:1.1 and add it to the dropping funnel. Control the reaction temperature to 10°C, open the dropping funnel, and slowly drop TFP into the kettle. After the dropwise addition, continue to stir in the kettle for 2.5h. Afterwards, the solution was rotated and evaporated under reduced pressure at 55 °C for 4 h to remove excess TFP, and the polarity-tunable ionic liquid [DBUH + ][TFP - ]. The experimental raw materials did not require any drying treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com