Reversed micelle supercritical CO2 dyeing system and method of polyester-cotton blended fabric

A polyester-cotton blended and dyeing system technology is applied in the field of polyester-cotton blended fabric dyeing, which can solve the problems of serious staining, fabric stains, and long dyeing time, achieve high dyeing efficiency, good solubility, and avoid staining and dyeing. spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

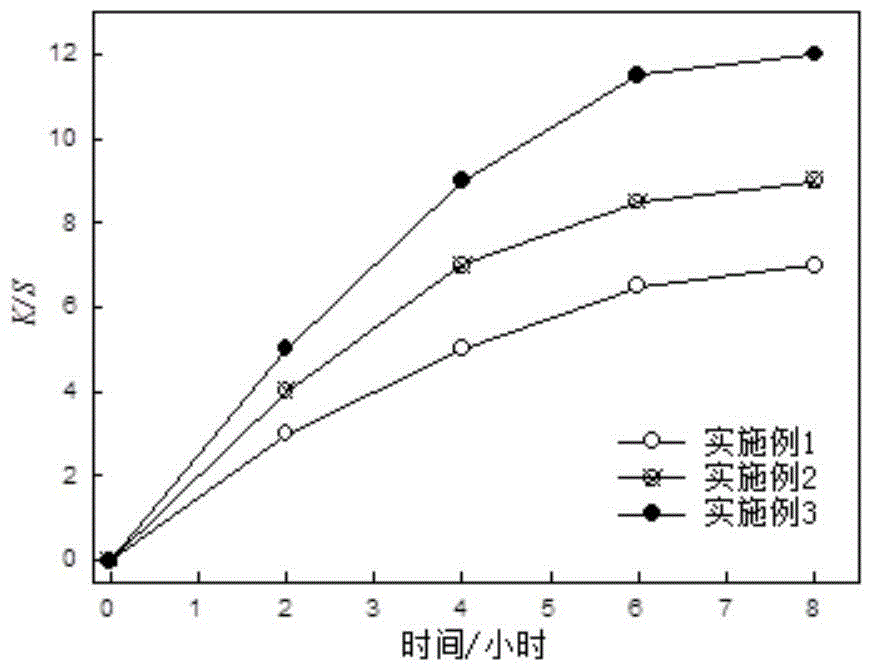

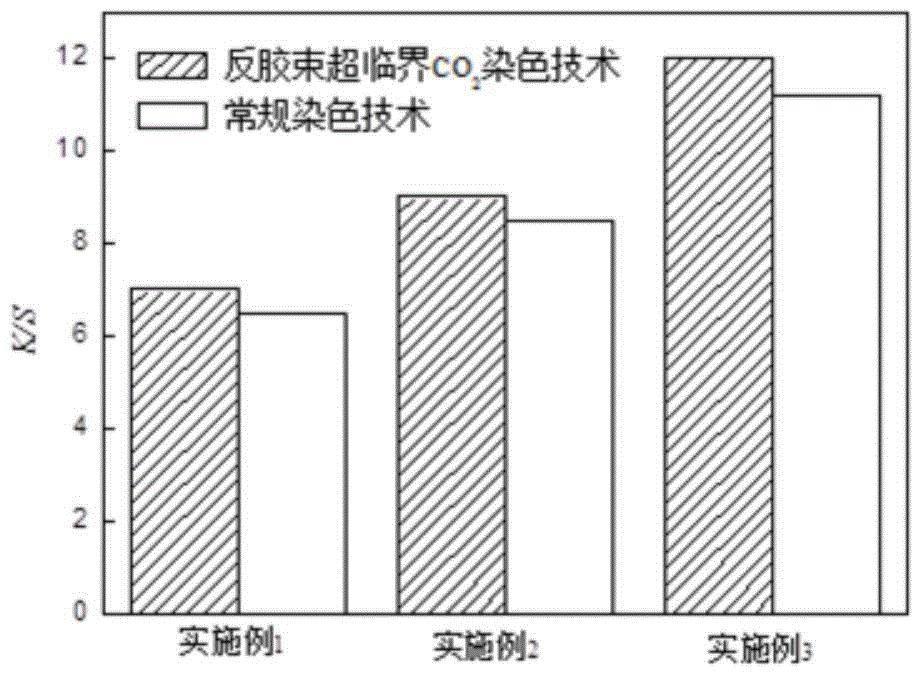

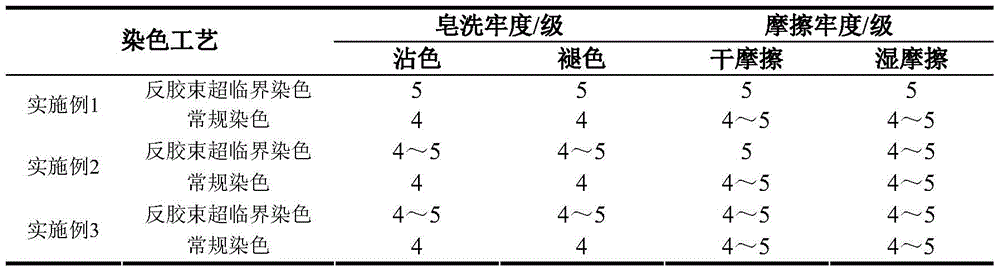

Embodiment 1

[0045] A reverse micellar supercritical CO2 dyeing system for polyester-cotton blended fabrics, comprising the following components in parts by weight:

[0046] Pentaethylene Glycol Monooctyl Ether: 15%

[0047] n-Pentanol: 26%

[0048] Reactive dyes: 0.03%

[0049] Disperse dyes: 0.03%

[0050] Supercritical carbon dioxide: 58.89%

[0051] Distilled water: 0.05%.

[0052] The dyeing method of the reverse micellar supercritical CO2 dyeing system of the polyester-cotton blended fabric comprises the following steps:

[0053] 1), pentaethylene glycol monooctyl ether, n-amyl alcohol, reactive dyes, disperse dyes and supercritical CO2 fluids form reverse micellar systems in a high-pressure container under 10MPa pressure;

[0054] 2) Put the polyester-cotton blended fabric in a high-pressure container, heat the high-pressure container to 40°C, and dye for 150 minutes;

[0055] 3), decompress the high-pressure container to normal pressure, take out the polyester-cotton blended ...

Embodiment 2

[0057] A reverse micellar supercritical CO2 dyeing system for polyester-cotton blended fabrics, comprising the following components in parts by weight:

[0058] Pentaethylene glycol monooctyl ether: 18%

[0059] n-Pentanol: 28%

[0060] Reactive dyes: 0.07%

[0061] Disperse dyes: 0.07%

[0062] Supercritical carbon dioxide: 51.86%

[0063] Distilled water: 2.0%.

[0064] The dyeing method of the reverse micellar supercritical CO2 dyeing system of the polyester-cotton blended fabric comprises the following steps:

[0065] 1), pentaethylene glycol monooctyl ether, n-amyl alcohol, reactive dyes, disperse dyes and supercritical CO2 fluids are formed in a high-pressure container under a pressure of 30Mpa to form a reverse micelle system;

[0066] 2) Put the polyester-cotton blended fabric in a high-pressure container, heat the high-pressure container to 130°C, and dye for 30 minutes;

[0067] 3), decompress the high-pressure container to normal pressure, take out the polyest...

Embodiment 3

[0069] A reverse micellar supercritical CO2 dyeing system for polyester-cotton blended fabrics, comprising the following components in parts by weight:

[0070] Pentaethylene glycol monooctyl ether: 22 parts

[0071] n-pentanol: 29 parts

[0072] Reactive dyes: 0.12 parts

[0073] Disperse dyes: 0.10 parts

[0074] Supercritical carbon dioxide: 42.78 parts

[0075] Distilled water: 6.0 parts.

[0076] The dyeing method of the reverse micellar supercritical CO2 dyeing system of the polyester-cotton blended fabric comprises the following steps:

[0077] 1), pentaethylene glycol monooctyl ether, n-amyl alcohol, reactive dyes, disperse dyes and supercritical CO2 fluids form reverse micellar systems in a high-pressure container under 20MPa pressure;

[0078] 2) Put the polyester-cotton blended fabric in a high-pressure container, heat the high-pressure container to 85°C, and dye for 90 minutes;

[0079] 3), decompress the high-pressure container to normal pressure, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com