Bridge thrusting slip device

A sliding device and jacking technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effect of avoiding rapid changes in structural elevation, preventing void phenomenon, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical features of the present invention more clearly understood, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

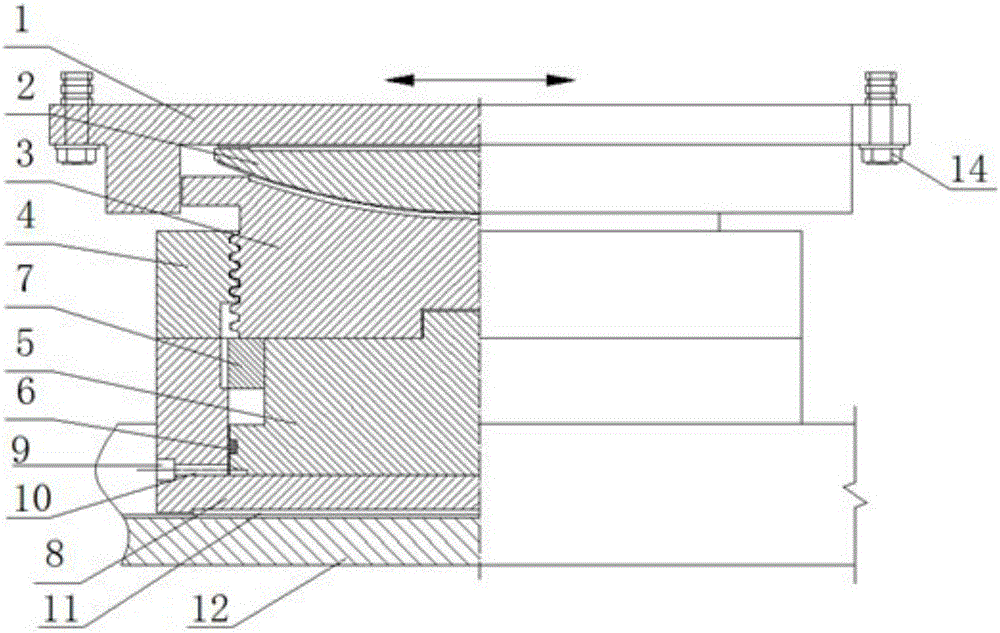

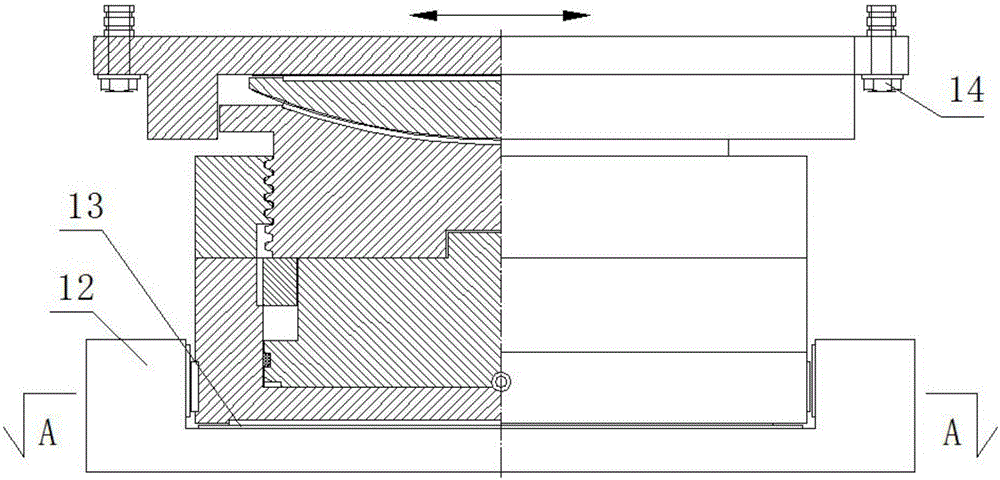

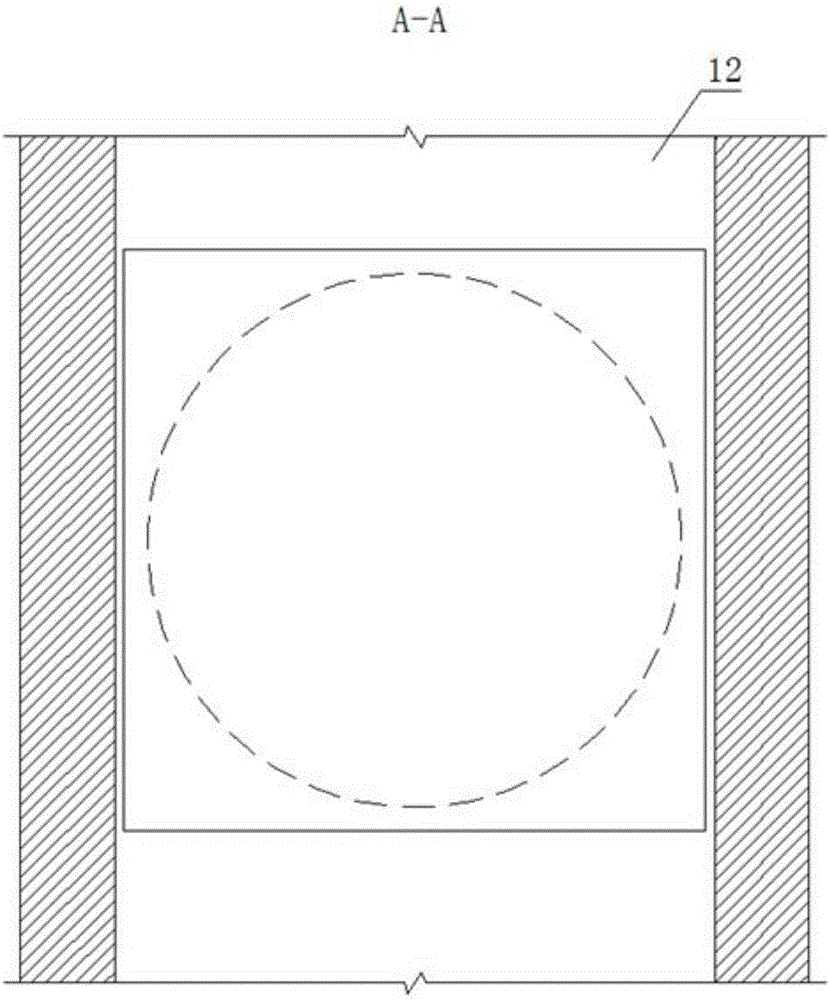

[0023] see figure 1 , figure 2 , image 3 , the bridge pushing and sliding device of the present invention includes an upper support plate 1 and a lower support plate 8, and grooves are respectively arranged on the upper support plate 1 and the lower support plate 8; the grooves of the upper support plate 1 A spherical crown liner 2 is installed inside, the upper plane of the spherical crown liner 2 is in contact with the bottom of the groove of the upper support plate 1, and the lower spherical surface of the spherical crown liner 2 is in contact with the radial direction of the stud 3 The end faces match each other, the stud 3 is threadedly connected to the lock nut 4, the flange on the upper part of the stud 3 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com