Karst cave backfilling and squeezing hammer and squeezing device

A technology of extruding device and extruding hammer, applied in filling and other directions, can solve the problems of reducing construction efficiency, increasing mechanical shifts and labor, and affecting the construction progress of project punching piles, so as to improve construction efficiency and improve karst caves. The effect of backfilling efficiency and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

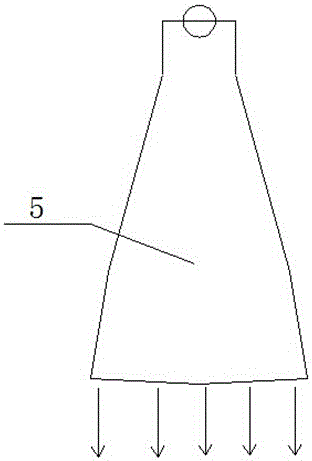

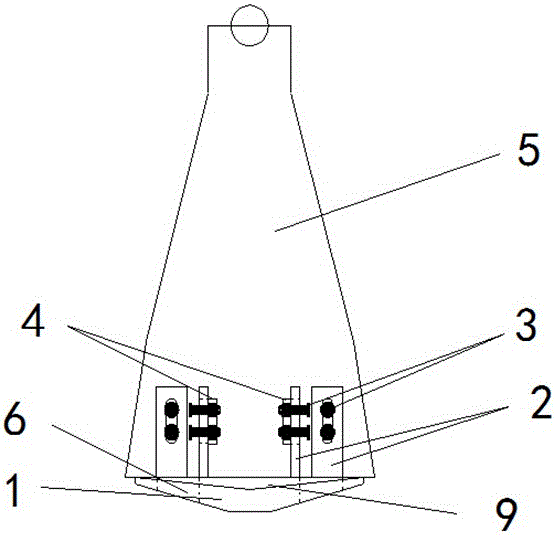

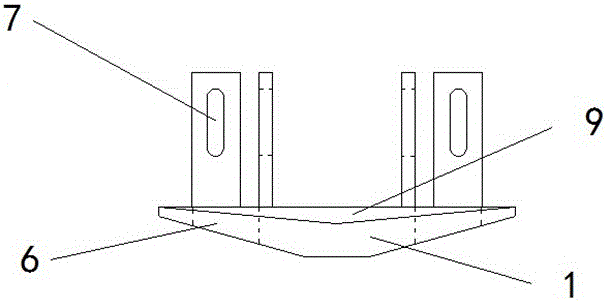

[0025] A karst cave backfill extrusion hammer, comprising an extrusion hammer body 1, the extrusion hammer body 1 is conical, and the extrusion hammer body 1 is provided with multiple grooves 9 and a plurality of pressure relief holes 6; wherein The groove 9 is located on the upper surface of the hammer body 1 and distributed across, the pressure relief hole 6 runs through the hammer body 1 and is evenly distributed along the circumference of the hammer body 1; the groove 9 is a right angle three Prism, the slope is inclined from the outside to the center; the pressure relief hole 6 is a fan-shaped hole.

Embodiment 2

[0027] A karst cave backfill extrusion device, comprising a hammer 5 and an extrusion hammer body 1, the extrusion hammer body 1 is fixed below the impact hammer 5, the extrusion hammer body 1 is conical, and the extrusion hammer body 1 is provided with a plurality of grooves 9 and a plurality of pressure relief holes 6; wherein the grooves 9 are located on the upper surface of the hammer body 1 and distributed across them, and the pressure relief holes 6 run through the body of the extrusion hammer 1 and Evenly distributed along the circumference of the extrusion hammer body 1; the groove 9 is a right-angled triangular prism, and the slope is inclined from the outside to the center; the pressure relief hole 6 is a fan-shaped hole.

[0028] It also includes a fixed steel plate 2, a high-strength bolt 3 and a fixed wing plate 4; wherein the fixed steel plate 2 is welded and fixed on both sides of each groove 9, and the fixed steel plate 2 is provided with an adjustable bolt anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com