Desilting method of gravel bed dredging system of immersed tube tunnel

A technology of immersed tube tunnel and subgrade bed, which is applied in the desilting field of gravel subgrade bed dredging system of immersed tube tunnel, which can solve the problems of affecting the installation accuracy of immersed tube, being easily affected by water flow, and poor anti-silting effect, etc. , to achieve the effect of good desilting effect, easy operation and strong operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

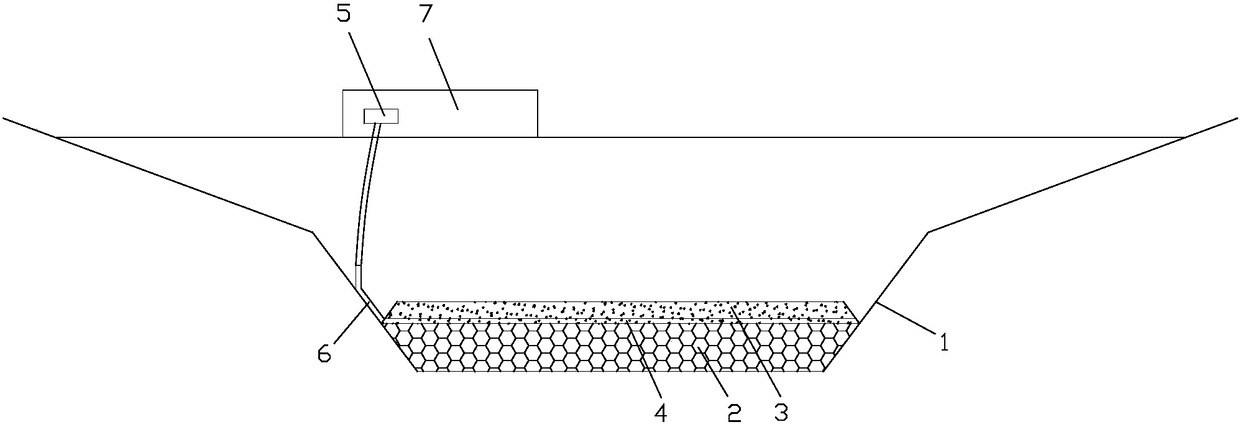

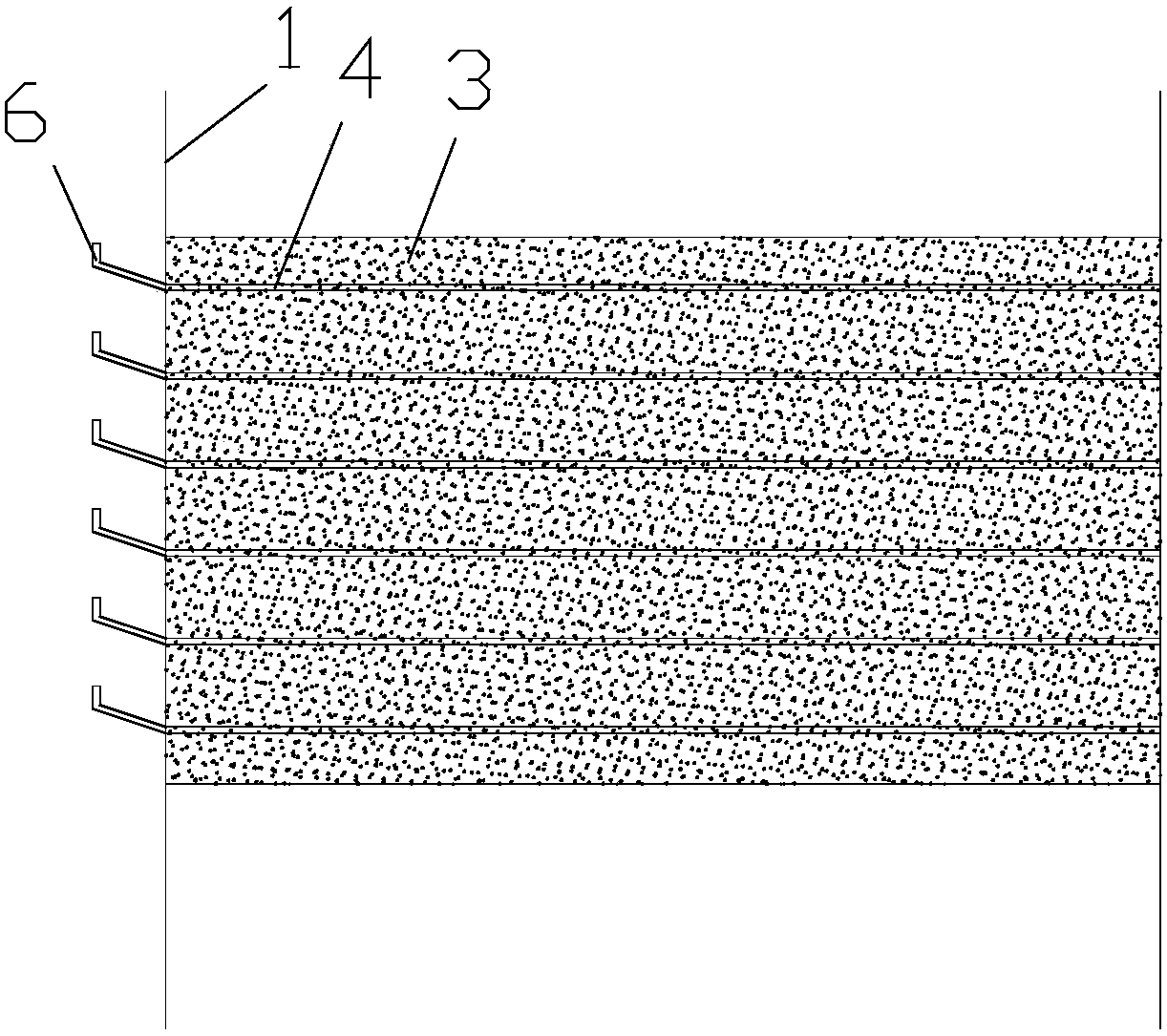

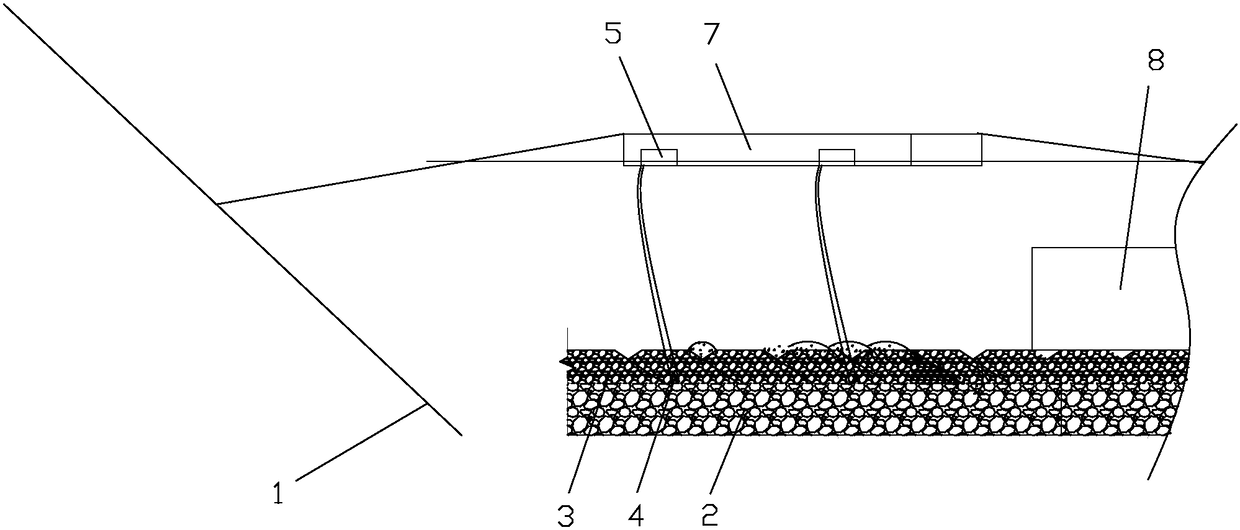

[0026] Such as Figures 1 to 3 As shown, the crushed stone bed dredging system of the immersed tube tunnel includes a foundation tank 1, and a bed is laid in the foundation tank 1, and the bed includes a block stone layer 2 and a crushed stone layer 3 arranged from bottom to top. The gravel layer 3 is provided with a dredging pipe 4 , and the wall of the dredging pipe 4 has holes, and the dredging pipe 4 is connected with a dredging pump 5 .

[0027] During construction, the foundation trench 1 is excavated first, then the subbase is treated, and then block stones are thrown into the foundation trench, and the block stones are rammed into a block stone layer 2 . Then the dredging pipe 4 is hoisted and deposited on the block stone layer 3 . Then lay the crushed stone layer 3 above the block stone layer 2 on which the dredging pipe 4 has been laid, and the dredging pipe 4 is embedded in the crushed stone layer 3, and the foundation bed is laid. Finally, connect the dredging pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com