Coarse aggregate voidage testing device and method

A testing device and coarse aggregate technology, applied in measurement devices, analysis materials, permeability/surface area analysis, etc., can solve the problems of large error in the results of coarse aggregate porosity, large influence of human factors, etc., and achieve convenient operation. , the principle is simple, the effect of high value precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

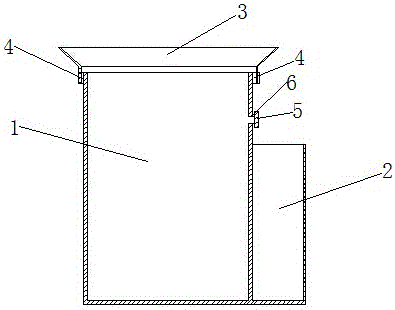

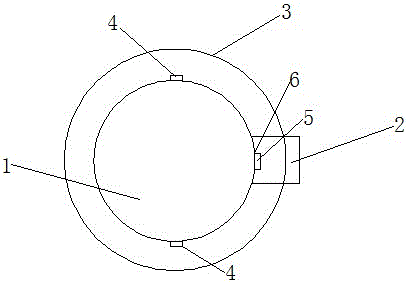

[0035] like figure 1 and figure 2 As shown, a coarse aggregate porosity test device includes a volume liter 1 and a water holding device 2, the volume liter 1 is a barrel structure, the side wall of the volume liter 1 is provided with openings, and the lower part of the outer wall of the volume liter 1 is also A water holding device 2 is provided, and the water holding device 2 is located below the opening, and a water gate 5 is provided on the outside of the opening, and a sealing strip 6 is also provided between the water gate 5 and the opening. The top is also provided with a protective cover 3, and the bottom of the protective cover 3 is provided with a protective cover support 4, and the protective cover 3 is fixed on the top edge of the volume liter 1 by the protective cover support 4.

[0036] The volume liter 1 is a cylindrical barrel structure.

[0037] The volume of the volume liter 1 is 10L, 20L or 30L.

[0038] The method using described a kind of coarse aggreg...

Embodiment 2

[0061] The device is the same as in Example 1.

[0062] The method using described a kind of coarse aggregate porosity testing device may further comprise the steps:

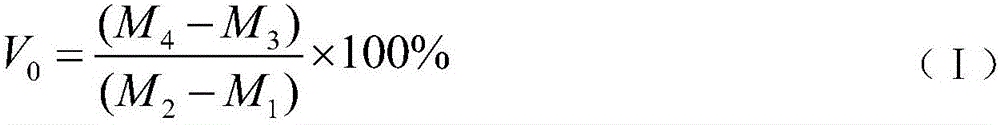

[0063] S1, volume liter calibration: use a balance to weigh the volume liter of 10L and the mass of the water holding device 2, denoted as M 1 , put the 10L volume liter on the level ground or workbench, inject water into the 10L volume liter, when it is about to be filled, slow down the injection speed, stop water injection when the water overflows slightly, let it stand for 10 seconds, open the water gate 5, Put water into the water storage device 2, wipe the outer surface of the 10L volume liter with a rag, move the 10L volume liter and the water storage device 2 to the platform scale, weigh the 10L volume liter, water and the total volume of the water storage device 2 Mass, denoted as M 2 ;

[0064] S2, porosity measurement: including the following sub-steps:

[0065] S21. Put the coarse aggregate to be ...

Embodiment 3

[0085] The device is the same as in Example 1.

[0086] The method using described a kind of coarse aggregate porosity testing device may further comprise the steps:

[0087] S1, volume liter calibration: use a balance to weigh the volume liter of 10L and the mass of the water holding device 2, denoted as M 1 , put the 10L volume liter on the level ground or workbench, inject water into the 10L volume liter, when it is about to be filled, slow down the injection speed, stop water injection when the water overflows slightly, let it stand for 12 seconds, open the water gate 5, Put water into the water storage device 2, wipe the outer surface of the 10L volume liter with a rag, move the 10L volume liter and the water storage device 2 to the platform scale, weigh the 10L volume liter, water and the total volume of the water storage device 2 Mass, denoted as M 2 ;

[0088] S2, porosity measurement: including the following sub-steps:

[0089] S21. Put the coarse aggregate to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com