Flow battery system structure

A liquid flow battery and system structure technology, applied in the direction of regenerative fuel cells, etc., can solve the problems of high equipment cost, large power consumption, and affecting battery performance, so as to improve operating efficiency, restore performance, and avoid power loss and interruption The effect of system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

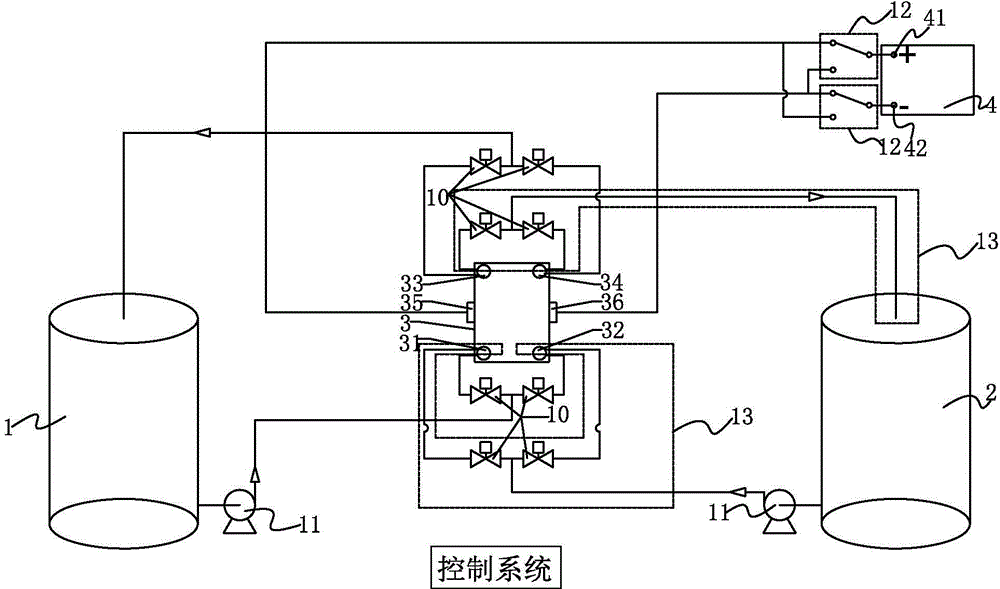

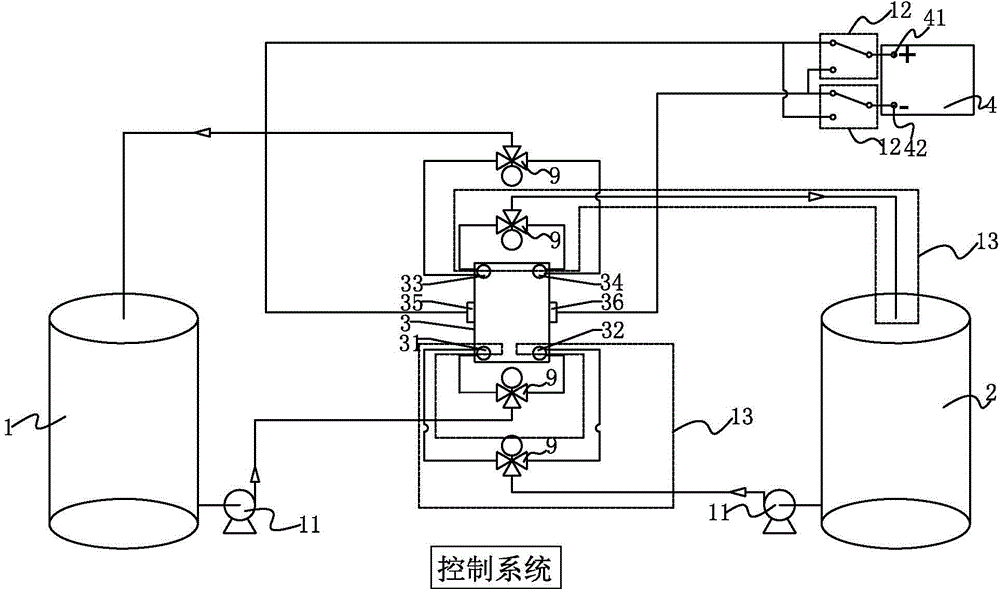

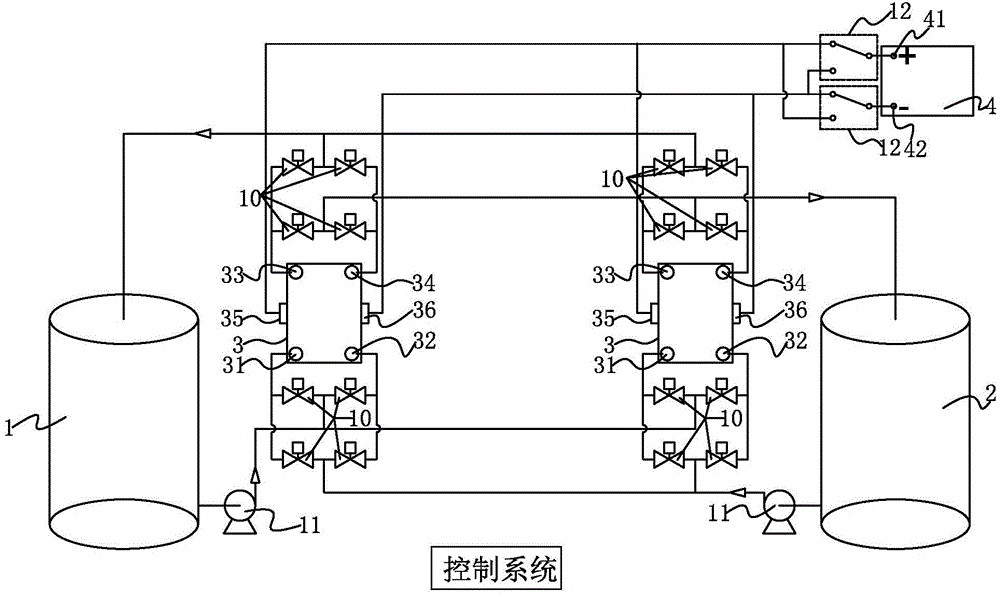

[0034] Such as figure 1 and figure 2The shown structure of a liquid flow battery system includes: at least one electric stack 3, a positive electrode electrolyte storage tank 1, a negative electrode electrolyte storage tank 2, and equipment 4 for power supply and / or electricity use; the electric stack 3 has The first electrical input and output end 35, the second electrical input and output end 36, the first electrolyte inlet 31, the second electrolyte inlet 32, the first electrolyte outlet 33 and the second electrolyte outlet 34; the positive electrode electrolyte storage Both the tank 1 and the negative electrode electrolyte storage tank 2 are connected to the first electrolyte inlet 31 and the second electrolyte inlet 32 of the stack 3; the first electrolyte outlet 33 and the second electrolyte outlet 33 of the stack 3 The outlets 34 are all connected to the positive electrode electrolyte storage tank 1 and the negative electrode electrolyte storage tank 2; the device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com