Flexible containers having flexible valves

A flexible container and container technology, applied in the field of containers, can solve the problems of unsightly, difficult to distribute flow products, limit decoration size and shape, etc., and achieve the effect of not easy to wear, low complexity and easy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

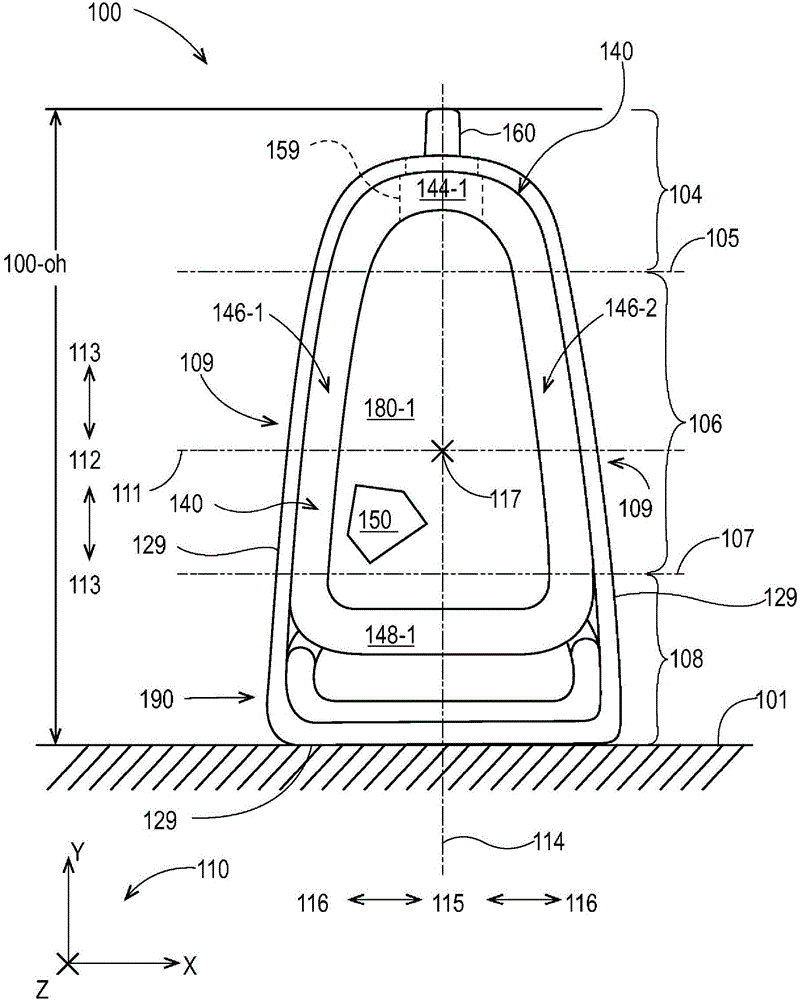

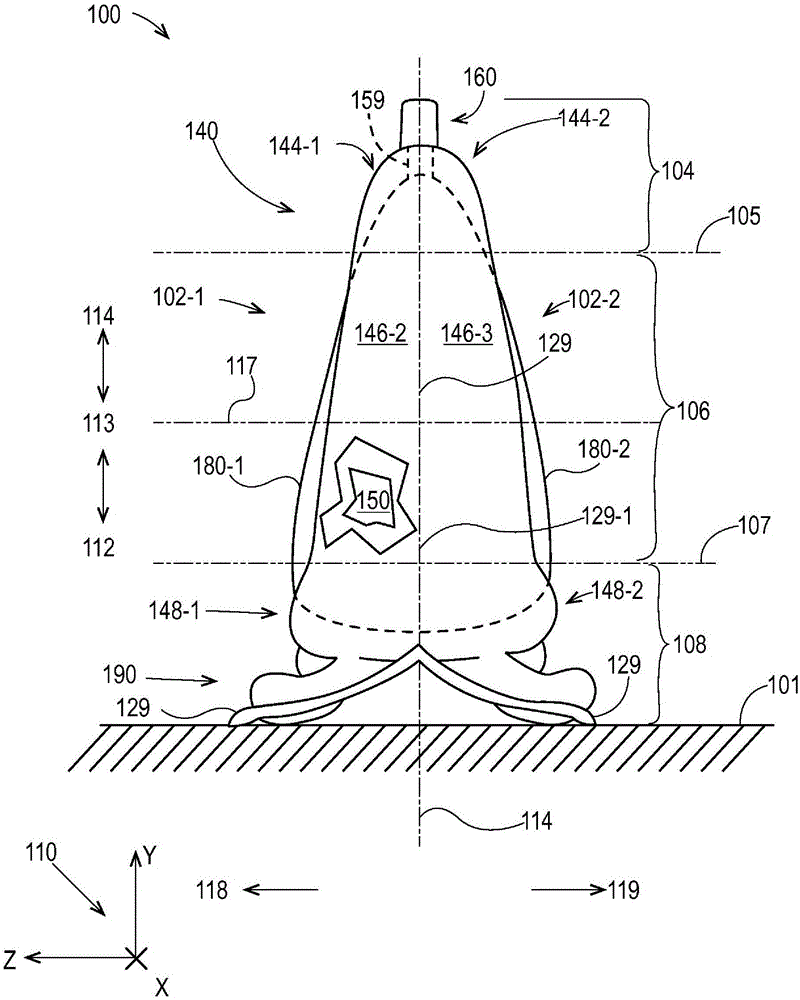

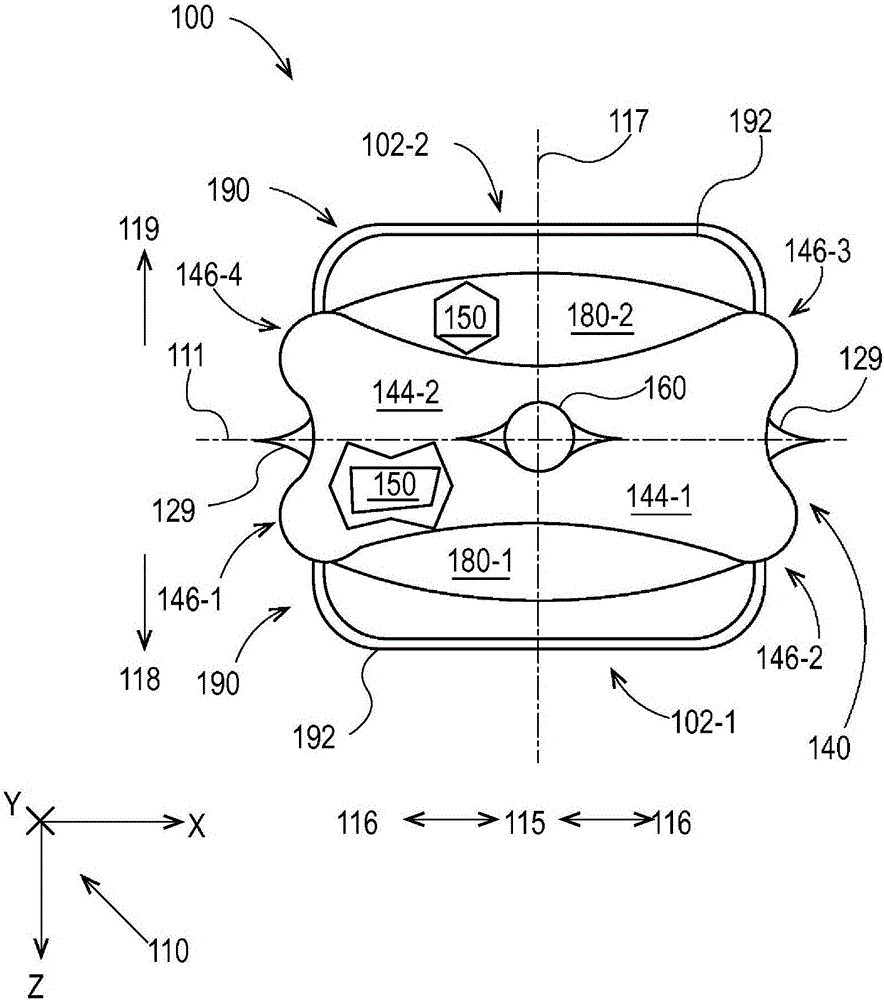

[0104] The present disclosure describes various embodiments of containers made from flexible materials. Because these containers are made of flexible materials, these containers can be less expensive to manufacture, can use less material and can be easier to decorate when compared to conventional rigid containers. First, these containers can be less expensive to manufacture because the transformation of flexible materials (from sheet form to finished product) generally requires less energy and complexity than the formation of rigid materials (from block form to finished product). Second, these containers can use less material because they are constructed with a novel support structure that does not require the use of thick core walls used in conventional rigid containers. Third, these flexible containers can be more easily decorated because the flexible material can be easily printed on before it is formed into a container. Fourth, these flexible containers are less prone to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com