Device for manually pouring foaming and carbonated beverages

A technology for carbonated beverages and beverages, applied in dispensing devices, valve devices, liquid distribution, etc., can solve the problems of equipment firmness and durability reduction, achieve rapid replacement and maintenance, high reliability and maintainability, and improve durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

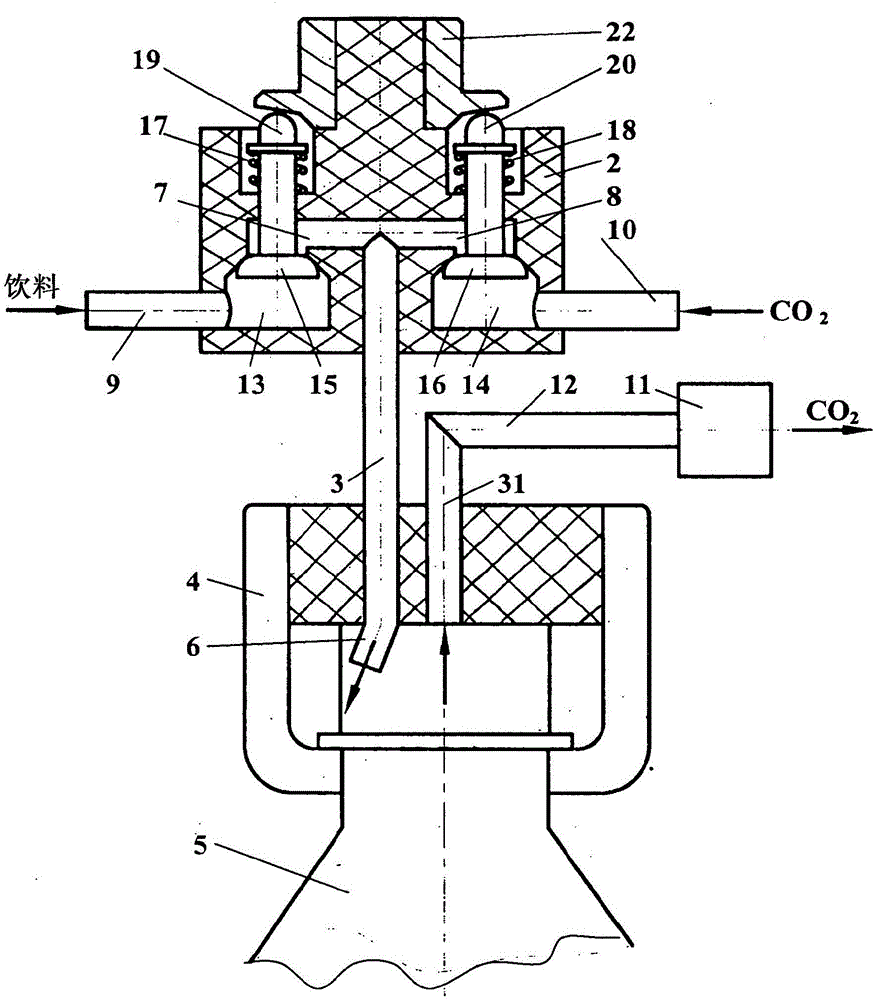

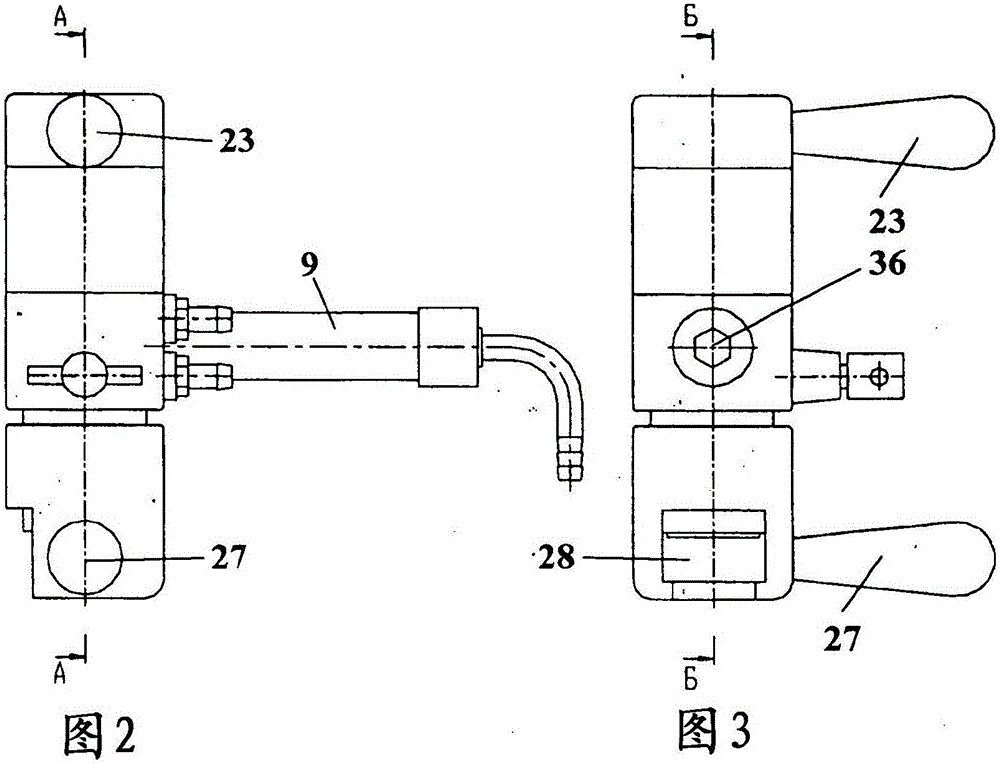

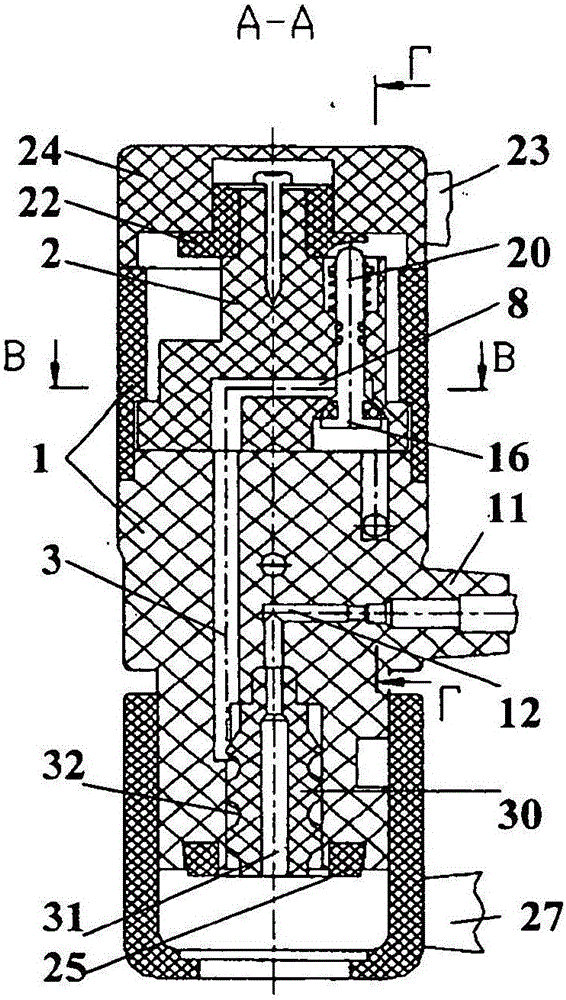

[0029] Devices for manual dispensing of sparkling and carbonated beverages ( Figures 1 to 5 ) comprising: an aggregate housing (aggregatehousing) 1 with a three-way flow switch 2, a discharge channel 3, and a unit 4 for securing the neck of a plastic bottle 5 to the open end 6 of the discharge channel 3 and positioned around the channel 3 . The discharge channel 3 is connected to the beverage supply fitting 9 and the gas supply fitting 10 via intermediate channels 7 and 8 arranged in the flow switch 2 . A control valve 11 is mounted in the housing 1 and connected to the cavity of the container 5 via a channel 12 . A three-way flow switch 2 is located within and removable from the housing 1 , said three-way flow switch being fixed to the housing 1 with a threaded connection.

[0030] The intermediate channels 7 and 8 of the flow switch 2 comprise axially symmetrical chambers 13 and 14 with valve seats and valves 15 and 16 with return springs 17 and 18 mounted in said valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com