A Rotatable Low-Frequency Ultrasonic Atomizing Cultivator

An ultrasonic atomization and cultivator technology, which is applied in cultivation, soilless cultivation, botany equipment and methods, etc., can solve the problems of insufficient sunlight in the shadow of three-dimensional cultivation, achieve larger amplitude, improve utilization efficiency, and increase atomization volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

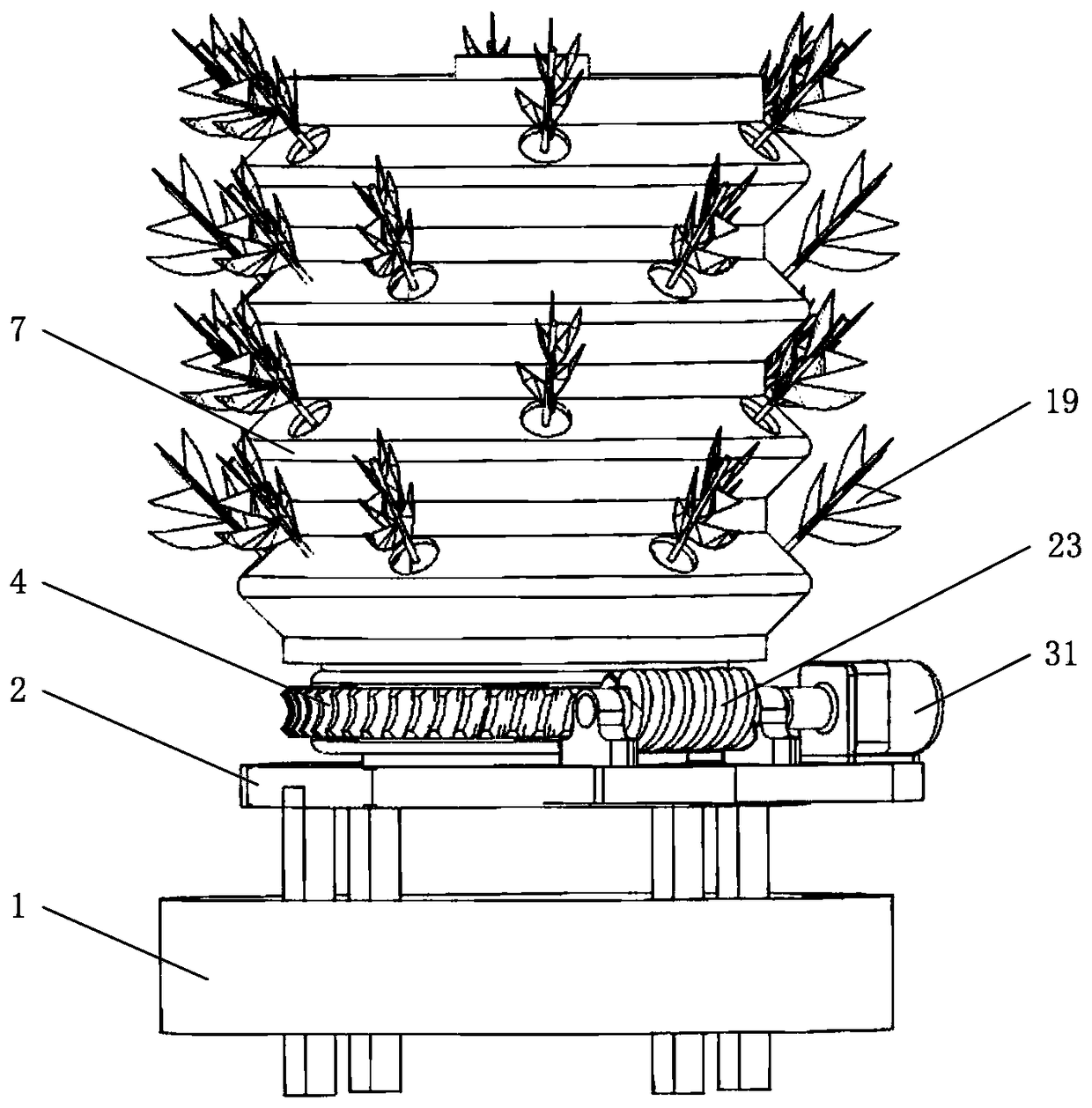

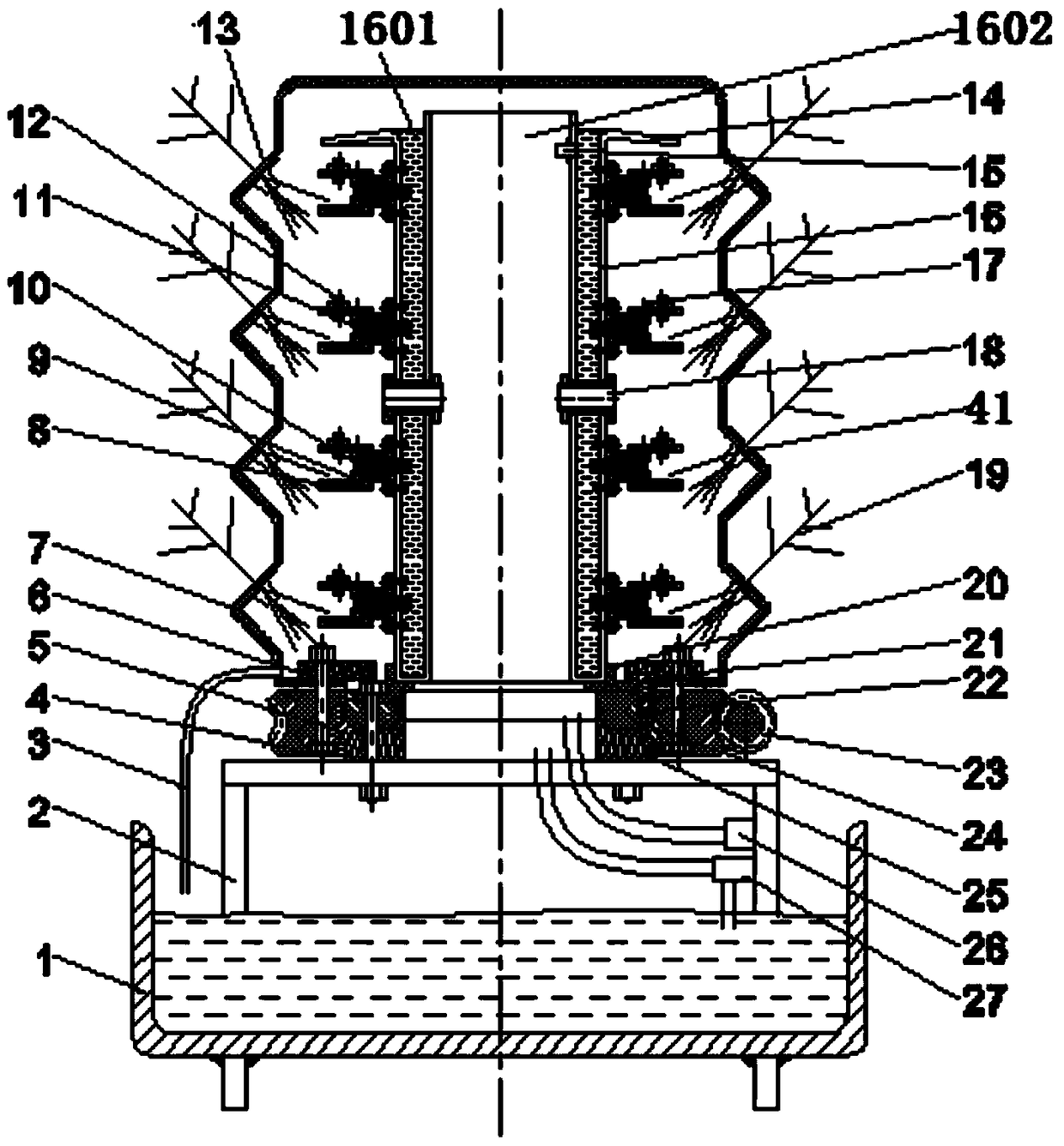

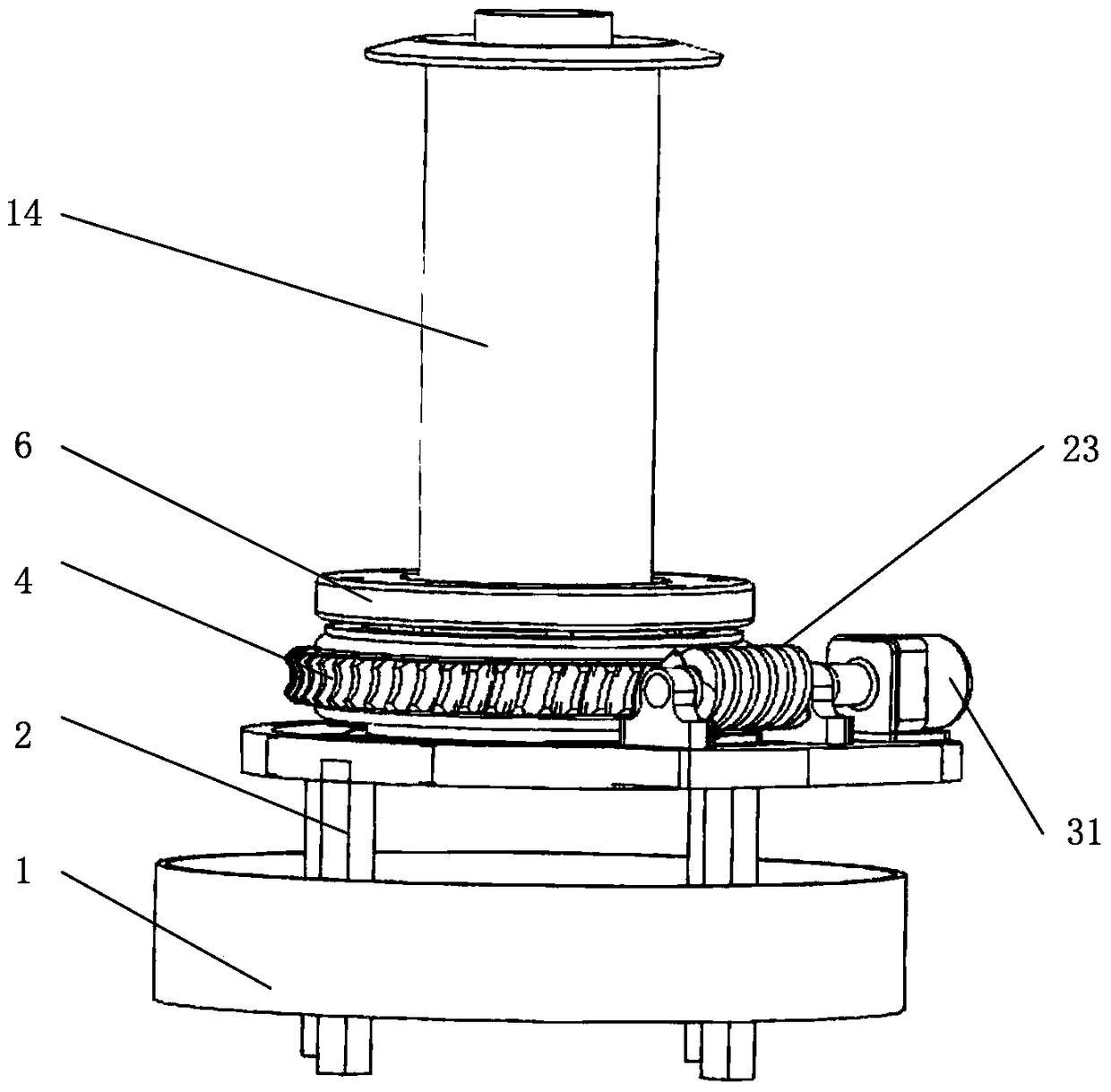

[0042] figure 1 , 2 Shown in and 3 is an embodiment of the rotatable low-frequency ultrasonic atomizing cultivator of the present invention, a kind of rotatable low-frequency ultrasonic atomizing cultivator, including nutrient solution pool 1, support 2, rotating platform, liquid storage Barrel 16, several atomizing nozzles, field planting barrel 7, air pump 26, replenishment pump 27, worm screw 23 and motor 31.

[0043] The bracket 2 is set in the nutrient solution pool 1; the rotating platform is set on the bracket 2; the planting bucket 7 is fixed on the rotating platform. Several planting holes 13 are evenly distributed on the barrel wall of the planting barrel 7, and a planting cup 41 is arranged in the described planting hole 13, and the roots of the plants 19 are placed in the cup 41 for planting. The planting bucket 7 can rotate 360 degrees under the drive of the rotating platform, so that the plants 19 in all directions of the column type planting bucket 7 can abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com