Cut noodle preservation method

A technology of cutting noodles and distilled water, applied in food preservation, food science, application and other directions, can solve the problems of short shelf life of cut noodles, and achieve the effect of reducing impact, avoiding adhesion, and facilitating daily life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

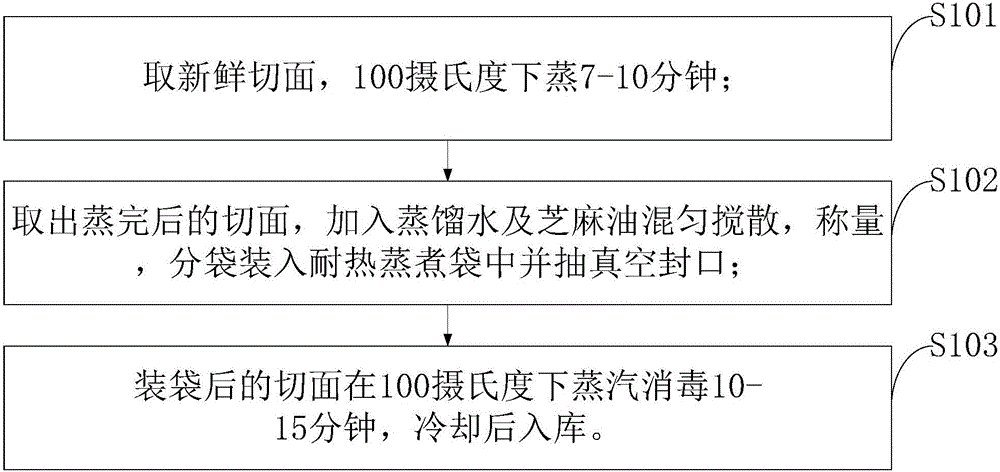

[0014] Such as figure 1 As shown, the cut surface quality preservation method of the embodiment of the present invention comprises the following steps:

[0015] S101, take fresh cut noodles and steam at 100 degrees Celsius for 7-10 minutes;

[0016] S102. Take out the sliced noodles after steaming, add distilled water and sesame oil, mix well, weigh them, put them into heat-resistant retort bags and seal them in vacuum;

[0017] S103. Steam sterilize the cut noodles after bagging for 10-15 minutes at 100 degrees Celsius, and put them into storage after cooling.

[0018] Further, add 100ml of distilled water and 10ml of sesame oil after steaming every 500g of cut noodles.

[0019] The present invention does not use preservatives, so that the shelf life of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com