Electric heating kettle capable of filling water from kettle wall

An electric kettle and kettle wall technology, which is applied to water-boiling utensils, kitchen utensils, household utensils, etc., can solve the problems of low possibility of mass production, high production cost, inconvenience and the like, and achieve low manufacturing cost and convenient structural manufacturing. , the effect of short paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

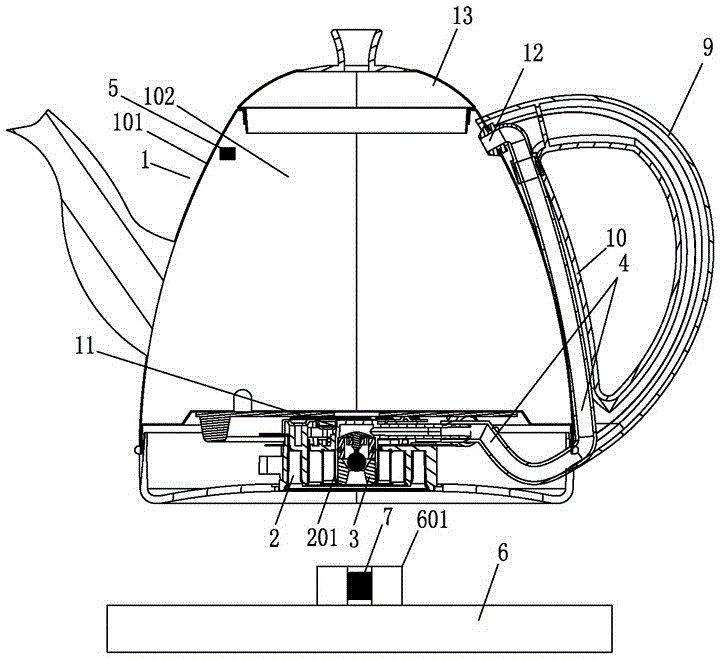

[0030] The first embodiment: as Figure 1 to Figure 3 as well as Figure 5 As shown, an electric kettle with water on the wall of the kettle includes a kettle body 1 and a kettle cover 13. A thermostat upper seat 2 is installed at the bottom of the kettle body 1. The thermostat upper seat 2 is provided with a central channel 201, and the central channel 201 A water inlet tube 11 is sleeved inside, one end of the water inlet tube 11 is connected to a water source, and the other end is connected with a water inlet pipe 4, and the water inlet pipe 4 extends upward along the kettle wall 101 of the kettle body 1 and connects with the inner chamber 102 of the kettle body 1. Pass.

[0031] The electric kettle with this structure utilizes the water inlet cylinder in the central channel 201 of the upper seat 2 of the thermostat. When the water enters the water inlet cylinder, it enters the inner cavity of the kettle body through the water inlet pipe along the wall of the kettle to rea...

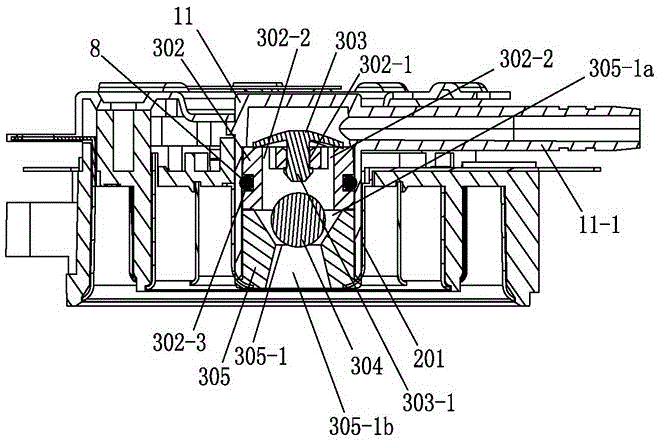

Embodiment approach

[0033] A water inlet valve core 3 with automatic opening and automatic sealing functions is installed in the water inlet cylinder 11. The water inlet valve core 3 includes a water inlet connecting frame 302, a variable leak-proof cap 303, a leak-proof steel ball 304 and a water inlet sealing sleeve. 305, the bottom of the water inlet cylinder 11 is connected to the water source, the top of the water inlet cylinder 11 is connected to the water inlet pipe 4, and a water inlet sealing sleeve 305 is fixed in the water inlet cylinder 11 near the bottom, and a central water inlet is provided in the water inlet sealing sleeve 305. Channel 305-1, the leak-proof steel ball 303 is placed on the upper end of the central water inlet channel 305-1, and the central water inlet channel 305-1 is sealed under the action of gravity, and the water inlet connecting frame 302 is installed above the water inlet sealing sleeve 305 , the variable leak-proof cap 303 is buckled on the central connection...

no. 2 example

[0042] The second embodiment: as Figure 4 As shown, similar to the first embodiment, the difference is that, after the water inlet pipe 4 extends upward along the kettle wall 101 of the kettle body 1, passes through the kettle cover 13 through the second water inlet joint 14 and connects with the kettle body 1 The inner cavity 102 communicates; as another embodiment, the water inlet pipe 4 may not be limited to be connected to the kettle wall 101, but may also extend out of the kettle wall 101 to connect with the kettle lid 13, and be connected to the kettle lid 13 through the second water inlet joint 14. The water outlet on the top can also use the kettle wall 101 to fill the water and then discharge the water through the kettle cover 13, which can also achieve the purpose of facilitating the water outlet; its advantage is: when the kettle body 1 is glass, the kettle cover 13 is correspondingly set to a glass body. The invented water inlet pipe 4 is connected with the pot li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap