Time-controlled release MT (metoprolol tartrate) pellets and preparation method thereof

A technology of metoprolol tartrate and tartaric acid, which is applied in directions such as pharmaceutical formulations, microcapsules, and drug combinations, can solve problems such as unsatisfactory drug release speed and limited pore-forming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] a. Prescription and preparation of metoprolol tartrate drug-loaded pellets (1000 grains):

[0050]

[0051] Preparation process: HPMC is added to 80% ethanol solution of metoprolol tartrate, and talcum powder is added under continuous stirring. A fluidized bed is used to apply the drug in the way of bottom spraying, and after the drug application is completed, the fluidized drying is continued at 39° C. for 2 hours to prepare the drug-loaded pellets.

[0052] B, prescription and preparation of metoprolol tartrate swelling layer pellets (1000 grains):

[0053] CC-Na: 56.875g

[0054] PVPK90: 8.125g

[0055] Preparation process: disperse croscarmellose sodium in water, dissolve polyvinylpyrrolidone K90 in ethanol, and mix the two solutions to obtain a swelling layer coating solution. Fluidized bed coating is adopted, and the swelling layer is coated on the drug-loaded pellet core by bottom spraying technology.

[0056] C, prescription and preparation of metoprolol ...

Embodiment 2

[0060] a. Prescription and preparation of metoprolol tartrate drug-loaded pellets (1000 grains):

[0061]

[0062] B, prescription and preparation of metoprolol tartrate swelling layer pellets (1000 grains):

[0063] CC-Na: 56.875g

[0064] PVPK90: 8.125g

[0065] C, prescription and preparation of metoprolol tartrate time-released pellets (1000 grains):

[0066]

[0067] The preparation method is the same as in Example 1.

Embodiment 3

[0069] a. Prescription and preparation of metoprolol tartrate drug-loaded pellets (1000 grains):

[0070]

[0071] B, prescription and preparation of metoprolol tartrate swelling layer pellets (1000 grains):

[0072] CC-Na: 56.875g

[0073] PVPK90: 8.125g

[0074] C, prescription and preparation of metoprolol tartrate time-released pellets (1000 grains):

[0075]

[0076] The preparation method is the same as in Example 1.

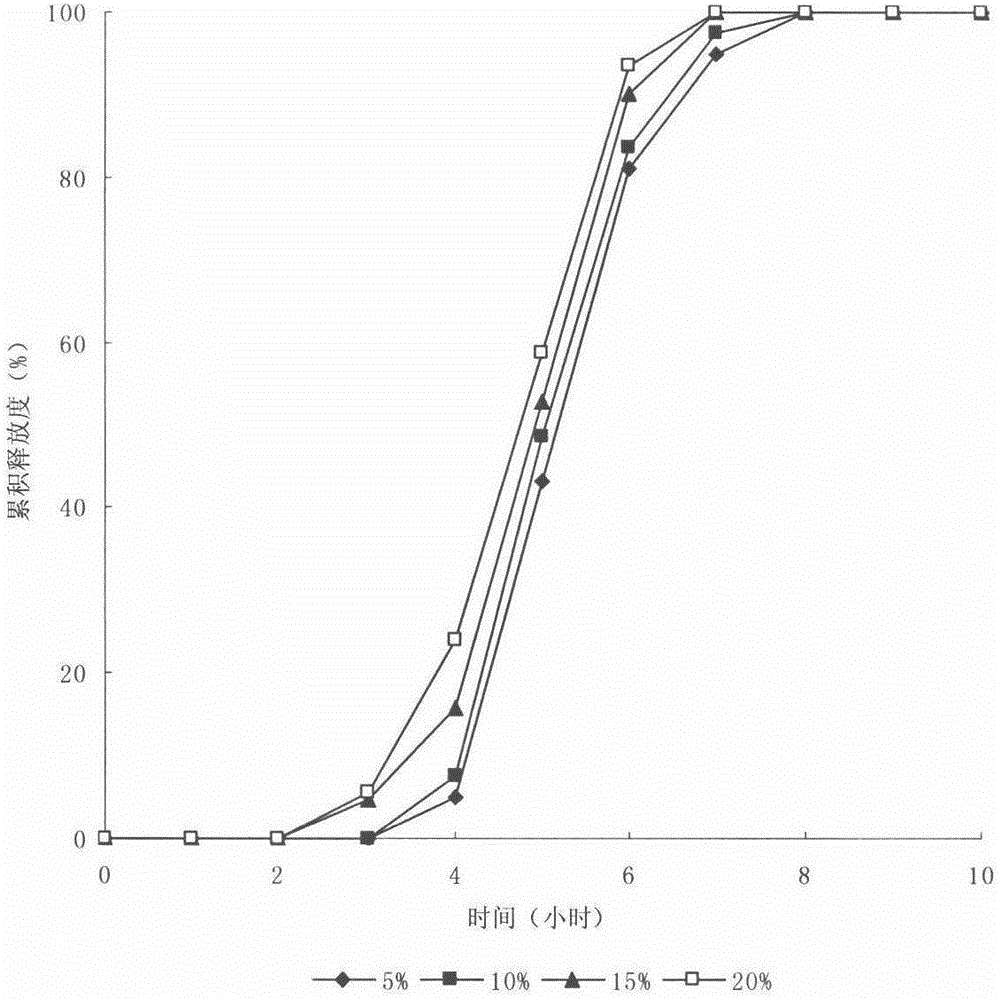

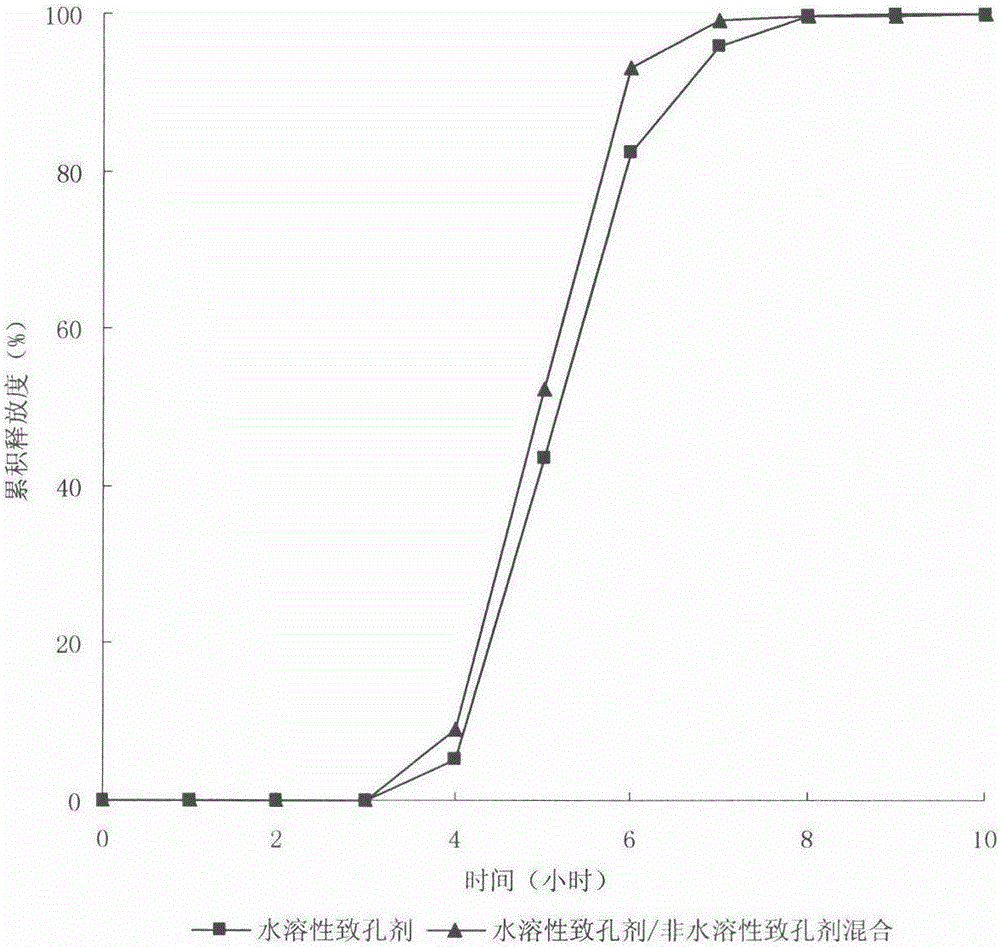

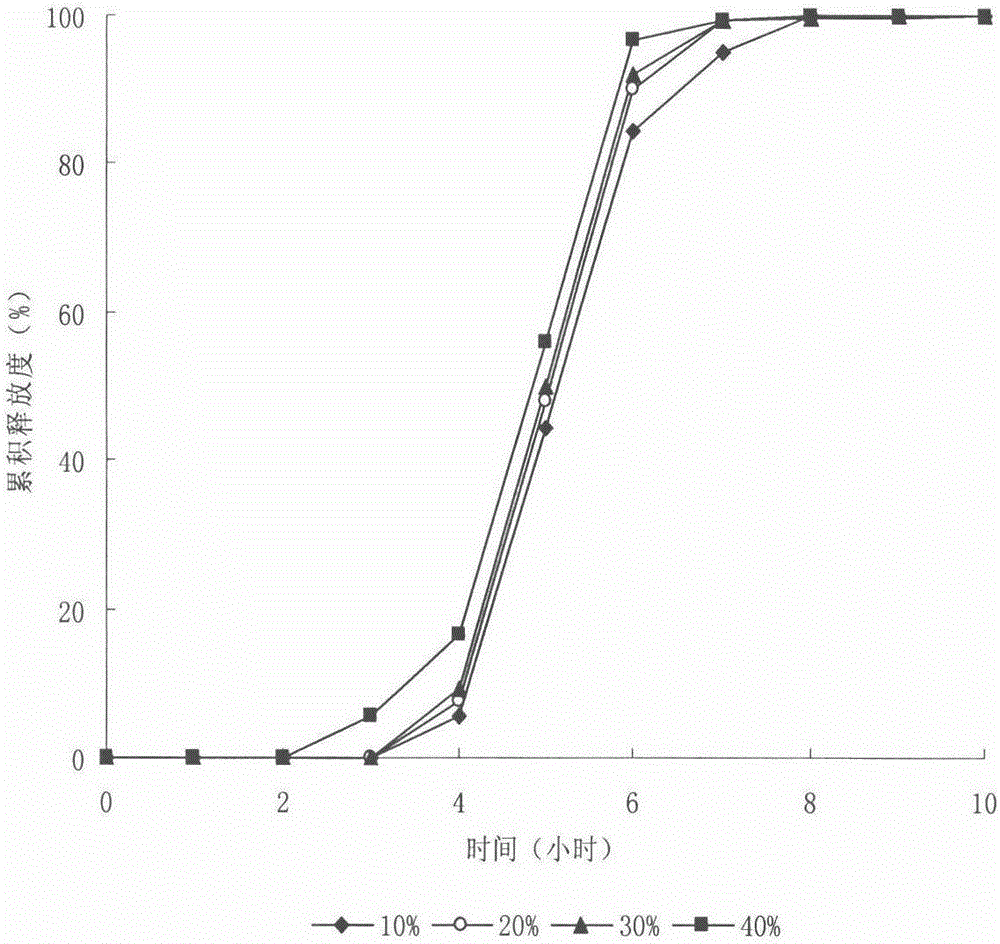

[0077] Table 1 Embodiment 1~3 cumulative release (%)

[0078] time (h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com