Vibrating and beating filter press capable of realizing one-time pulling-open

A technology of filter press and vibrating shaft, which is applied in the field of filter press, can solve the problems of low work efficiency, heavy workload of manual slag removal, and production accidents of spraying materials, etc., and achieves simple structure, good effect of cake falling and slag removal, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

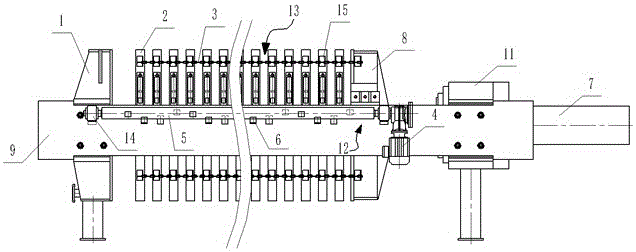

[0012] Below in conjunction with accompanying drawing, specific embodiment is further elaborated:

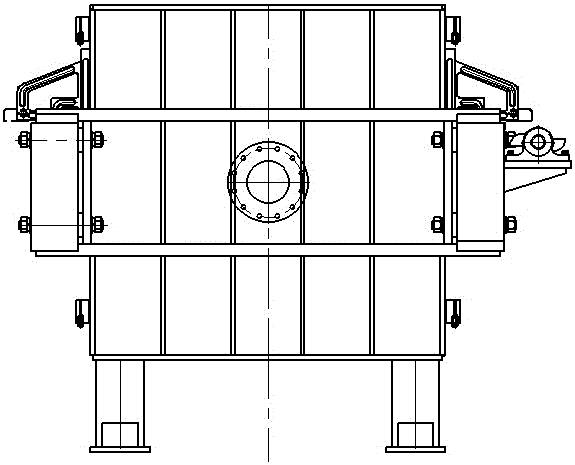

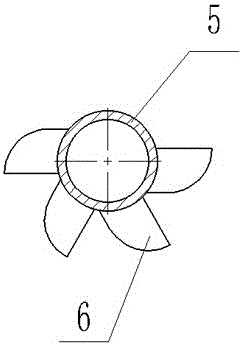

[0013] Such as Figure 1 to Figure 4 As shown, a one-time pulling and vibrating filter press includes an oil cylinder seat 11, a thrust plate 1, a pressing plate 8, a main beam 9, a filter plate 2, and an oil cylinder 7, and also includes a vibrating mechanism 12 and a primary plate pulling mechanism. 13. The rapping mechanism 12 includes the rapping shaft 5, the reduction motor 4 and the bearing 14, the bearing 14 is installed on the side of the main beam 9, the reduction motor 4 is installed on the side of the main beam 9, and the two ends of the rapping shaft 5 are installed on the bearing 14 On the top, one end of the rapping shaft 5 is also installed on the reduction motor 4, and there are regularly arranged claws 6 on the rapping shaft 5, and the primary pulling mechanism 13 includes an L-shaped chain plate 15, a chain 3, and an L-shaped chain The plate 15 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com