Method for making fabric of automobile-trunk cover plate

A technology for a trunk lid and a manufacturing method, which is applied to chemical instruments and methods, vehicle components, lamination auxiliary operations, etc., can solve the problems of affecting the appearance, the edges cannot be completely aligned, and the cost is high, and the effect of solving the high cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Examples of these preferred embodiments are illustrated in the accompanying drawings. The embodiments of the invention shown in and described with reference to the drawings are merely exemplary, and the invention is not limited to these embodiments.

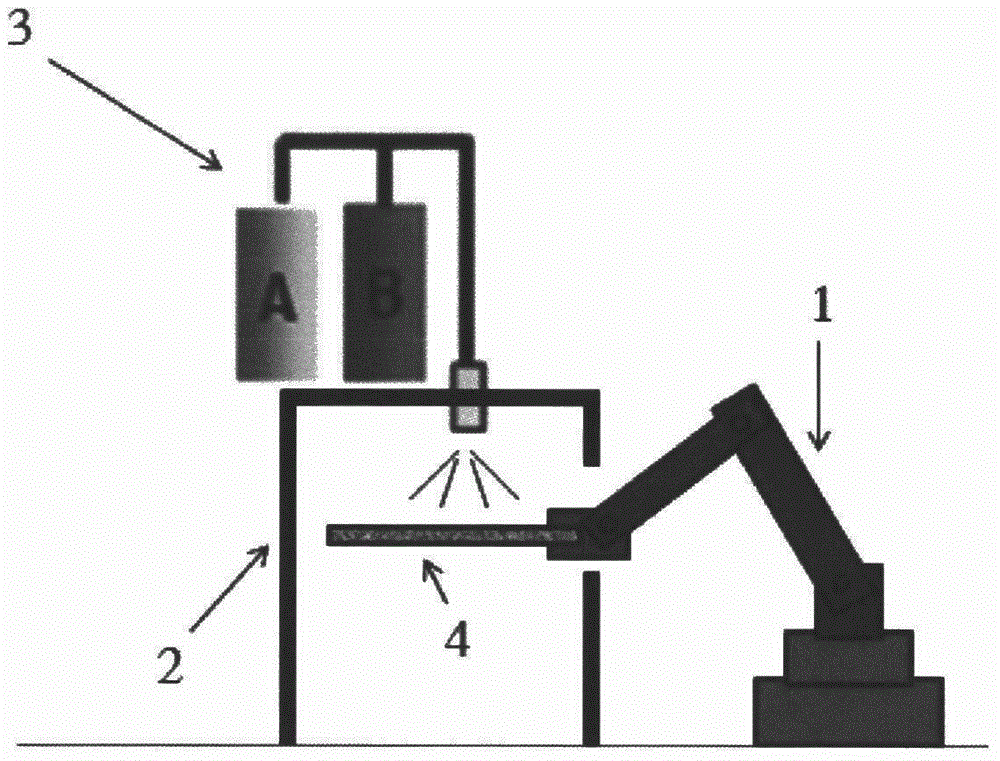

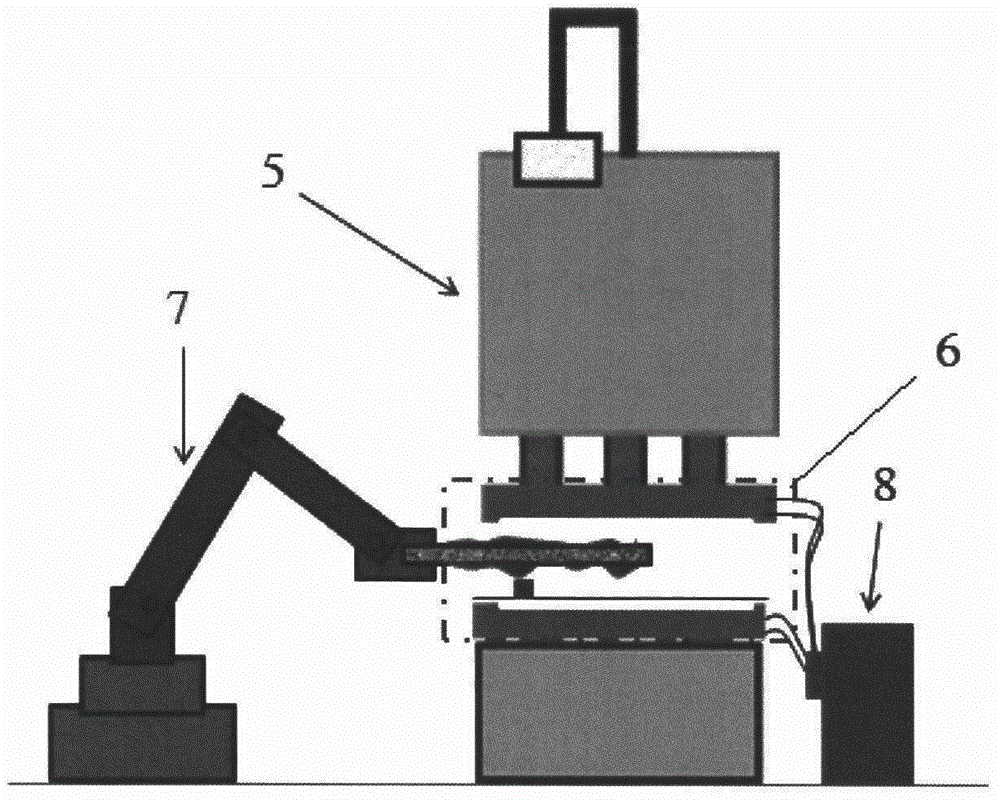

[0039] The method for manufacturing the fabric of the trunk cover of an automobile comprises the following steps.

[0040] 1. Cutting

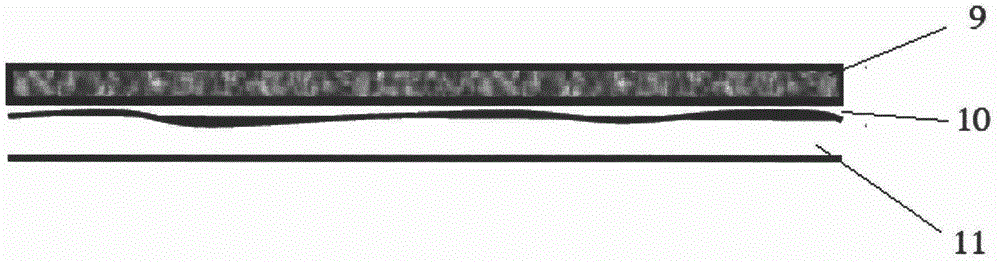

[0041] The glass fiber layer sheet and the honeycomb paperboard are cut into suitable blanks, and then a laminated structure is formed, and the laminated structure includes a glass fiber layer, a honeycomb paper core and a glass fiber layer formed sequentially.

[0042] Two, spray PU (polyurethane)

[0043] The stacked glass fiber layer and honeycomb p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com