Rice dumpling packing machine and packing method thereof

A packaging machine and rice dumpling technology, applied in packaging and other directions, can solve the problems of inability to realize packaging box forming, filling and separation, etc., and achieve the effect of facilitating later separation, reducing strength and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

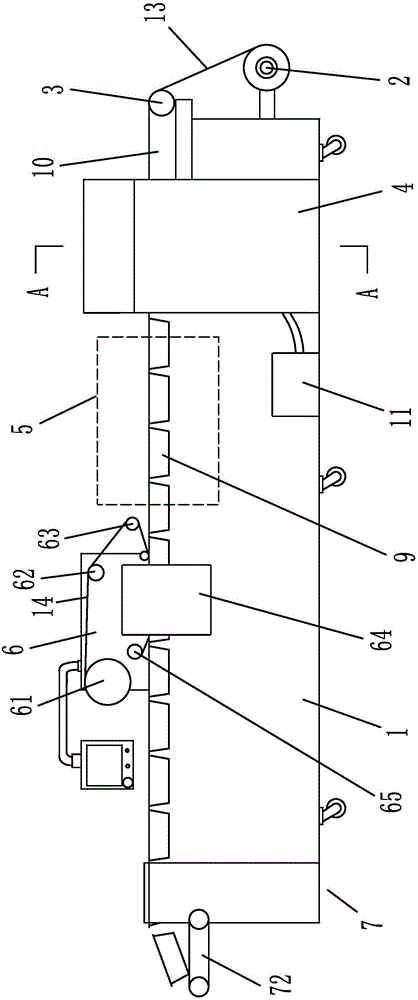

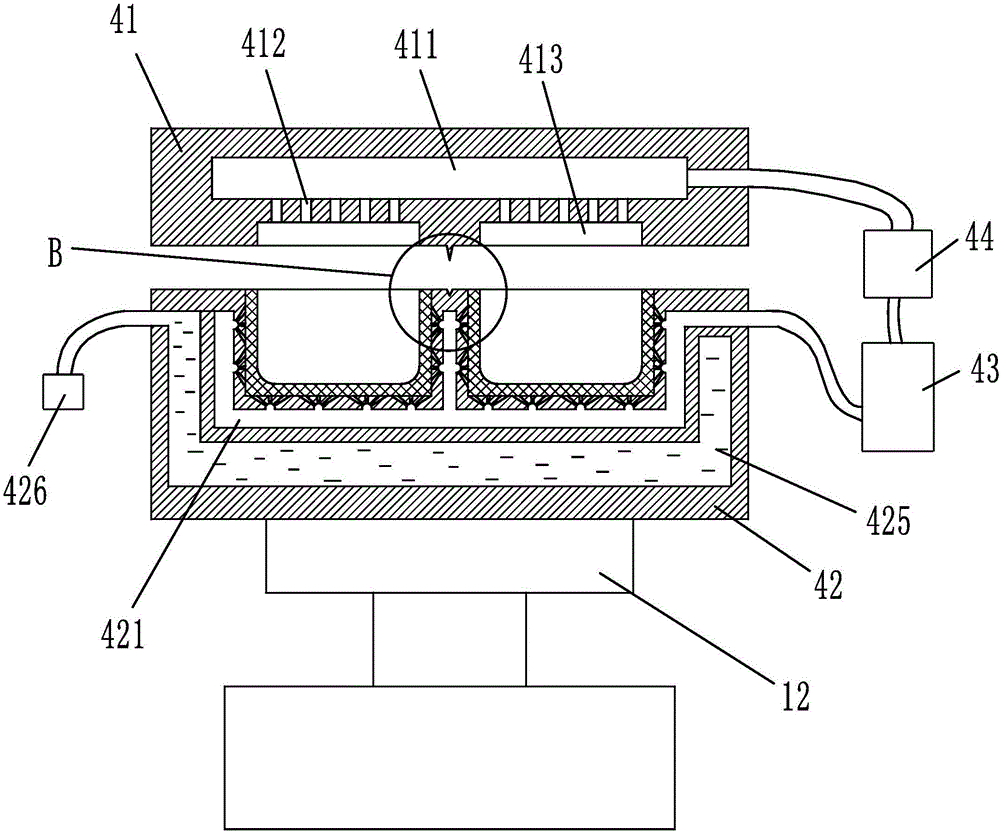

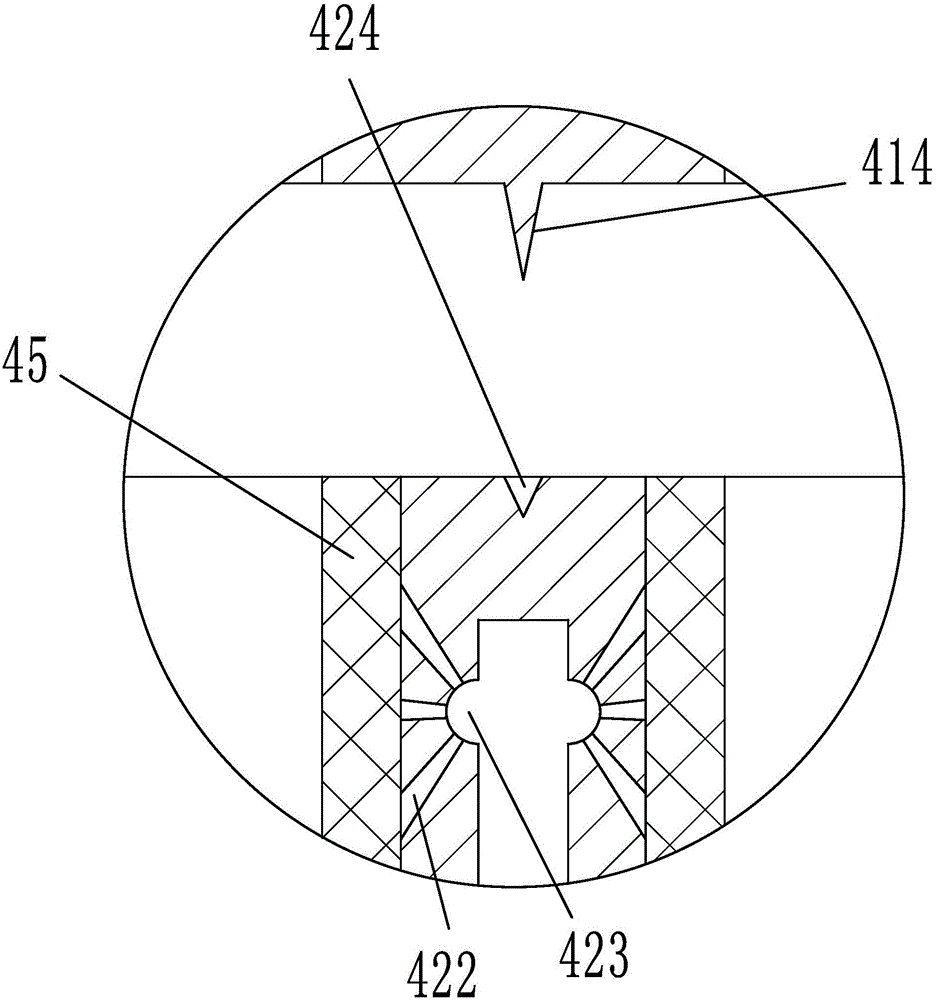

[0027] Embodiment 1: as figure 1 Shown, a kind of zongzi packaging machine comprises frame 1, control unit 11 and feed mechanism 10 positioned on the frame, also includes bottom film winding mechanism 2, bottom film output mechanism 3 arranged in sequence along the feed direction , packaging box forming device 4, rice dumpling filling area 5, top film capping mechanism 6. The frame is provided with a packing box separating mechanism 7, and the packing box separating mechanism is located at the end of the feeding direction. like Figure 9 As shown, the packaging box separation mechanism includes two guide plates 71, which are symmetrically arranged in an inverted "eight" shape. One end of the two guide plates is provided with a conveyor belt 72, and the height of the conveyor belt is smaller than that of the feed mechanism. The packaging box molding device includes an upper mold 41 and a lower mold 42. The bottom of the lower mold is provided with a lifting mechanism 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com