Aerobic-anoxic-anaerobic biochemical reactor and continuous sewage processing method

A biochemical reactor and reactor technology, applied in the field of denitrification and phosphorus removal, sewage biological decarbonization, aerobic-anoxic-anaerobic biochemical reactor and continuous sewage treatment, can solve sludge confusion and different impacts The treatment effect of the workshop section, the large area of the reactor, etc., achieve the effect of maintaining the flow direction of sewage, improving the efficiency of sewage treatment, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

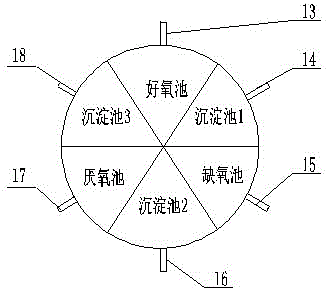

[0031] The biochemical reactor of the invention is used for a separate denitrification process.

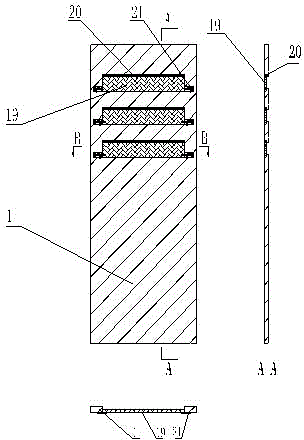

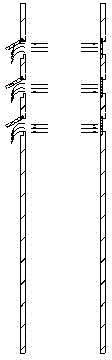

[0032] The conversion of nitrogen in the biological denitrification process of sewage mainly includes nitrification and denitrification, in which nitrification is carried out under aerobic conditions, and denitrification is carried out under anoxic conditions. First of all, close all the non-return water-passing plates on the partitions 1 and 5 with the bolts, open the water-passing holes of the aerobic tank and the sedimentation tank 2, and close the other water-passing holes, so that the sewage passes through the water-passing holes of the aerobic tank It enters through the mouth and exits through the water outlet of the sedimentation tank 2. Due to the function of the non-return water filter, the sewage overflows in a clockwise direction, that is, flows through the aerobic tank-sedimentation tank 1-anoxic tank-sedimentation tank 2 in sequence. Sewage enters the aerobic tank at...

Embodiment 2

[0035] The biochemical reactor of the invention is used for a separate phosphorus removal process.

[0036] The most basic principle of biological phosphorus removal is to use the characteristics of anaerobic phosphorus release and aerobic phosphorus uptake by phosphorus-accumulating microorganisms in an anaerobic-aerobic or anaerobic-anoxic alternate operation system to achieve the purpose of phosphorus removal. For this process, the anaerobic tank and the aerobic tank are required, and all the non-return water plates on the partitions 3 and 5 are closed with the plugs, and the water outlets of the anaerobic tank and the sedimentation tank 1 are opened, and the other water outlets are are all closed, so that the sewage enters through the water hole of the anaerobic tank and exits from the water hole of the sedimentation tank 1. Due to the function of the non-return water plate, the sewage overflows in a clockwise direction, that is, the process is anaerobic tank-sedimentation...

Embodiment 3

[0039] The biochemical reactor of the invention is used for the process of denitrification and dephosphorization.

[0040] The ammonification of nitrogen in the biological denitrification process of sewage can be carried out under aerobic or anaerobic conditions, nitrification is carried out under aerobic conditions, denitrification is carried out under anoxic conditions, and biological phosphorus removal requires anaerobic ponds and The joint effect of aerobic tank, then can open the water-passing orifice in anaerobic tank and sedimentation tank 2 at this moment, close other water-passing orifice, make sewage enter by the water-passing orifice of anaerobic tank, by sedimentation tank 2 out of the water hole. Due to the function of the check water plate, the sewage overflows in a clockwise direction, that is, the technological process is anaerobic pond-sedimentation pond 3-aerobic pond-sedimentation pond 1-anoxic pond-sedimentation pond 2. At this moment, all non-return water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com