Pulp production equipment and production process

A technology of pulp and equipment, applied in the field of pulp production equipment and production technology, can solve the problems of increasing the process, not ensuring the accuracy of pressure measurement, affecting the normal operation of slag removal equipment, etc., and achieving the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

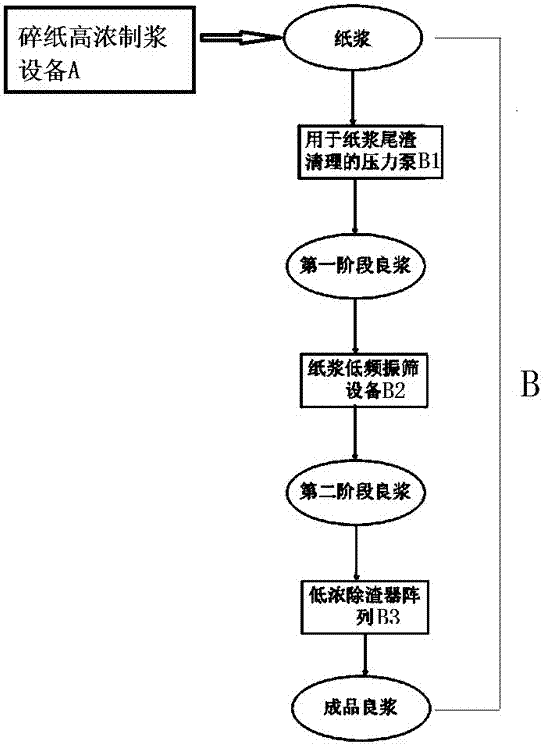

[0057] When this equipment cleans pulp, the pulp passes through the pressure pump used to clean pulp tailings to form the first-stage good pulp, the first-stage good pulp passes through the pulp low-frequency vibrating screen equipment to form the second-stage good pulp, and the second-stage good pulp is passed through The array of low-consistency slag cleaners is used to produce good pulp.

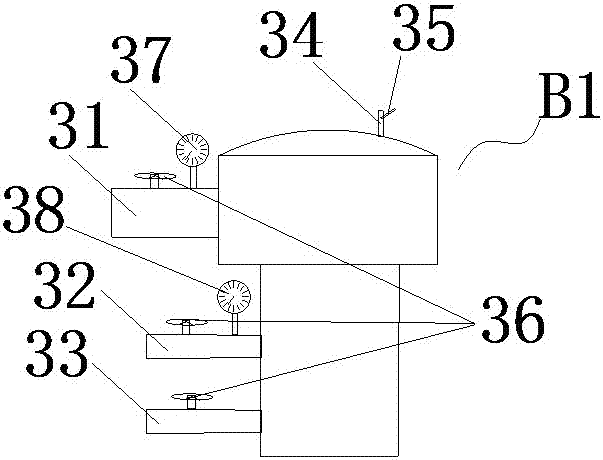

[0058] In the process of the first stage of good pulp, the pressure pump collects the pulp through the slurry inlet pipe 31, and the impurities in the pulp are filtered out by the impurity trap in the screening part to form a slurry, and the slurry is discharged through the slurry outlet pipe 33 , the filtered pulp becomes the good pulp in the first stage and flows to the pulp low-frequency vibrating screen equipment through the good pulp outlet pipe. The pressure in the pump keeps increasing. When the pressure difference between the slurry inlet pipe 31 and the good slurry outlet pipe 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com