High-level roadway communicated drill hole circulating water type mine cooling system and method

A circulating water, high-level technology, applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problems of increasing ventilation and mine air-conditioning cooling, waste of resources, increasing production investment, etc., to improve heat exchange efficiency. , The effect of saving heat demand and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

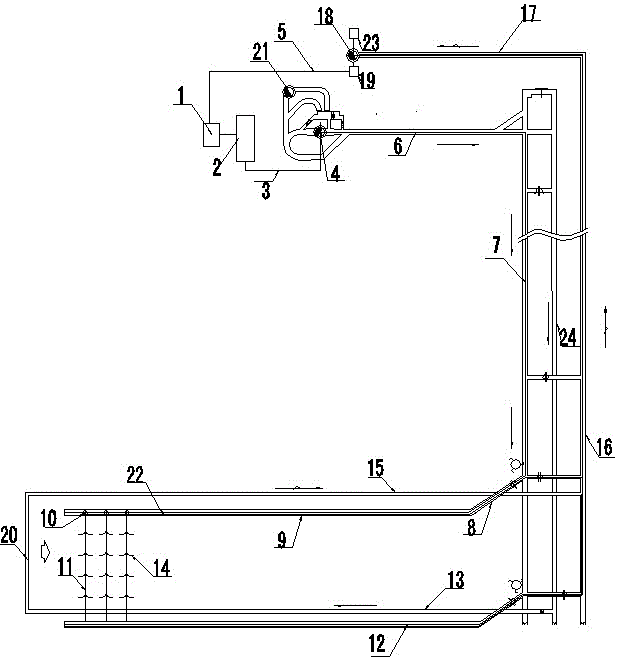

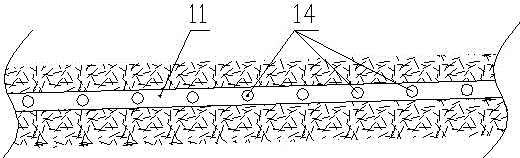

[0032] figure 1 The directions of the solid arrows in each place show the flow direction of the wind at that place; figure 1 The hollow arrow on the left side of the mark 11 shows the direction of excavation and recovery of the mining face.

[0033] In the mine, the recovery working face is located between the first high level roadway 9 and the next working face high level roadway 12, and is located below the floor of the first high level roadway 9 and the next working face high level roadway 12.

[0034] Such as figure 1 and figure 2 As shown, the mine cooling system of high-level lane Unicom borehole circulating water type of the present invention includes a thermal unit 1, the water outlet of the thermal unit 1 is connected with the water inlet of the industrial chiller 2 through a connecting pipeline, and the industrial chiller 2 The water outlet is connected with a water inlet pipeline 3, and the water inlet pipeline 3 leads to the air inlet transportation alley 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com