Temperature measuring device and method for graphene drilling machining

A temperature measurement and graphene technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as poor stability and complex structure, and achieve the effect of ensuring quality, reducing defects, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

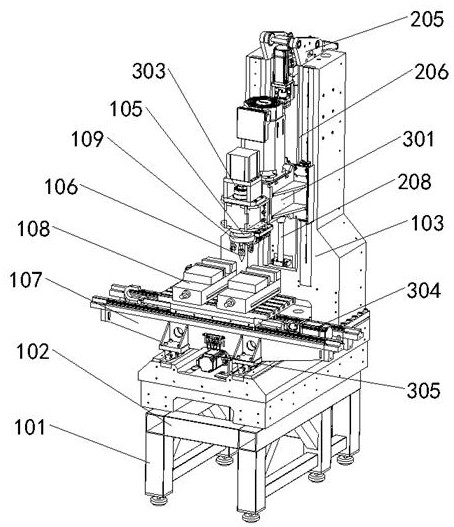

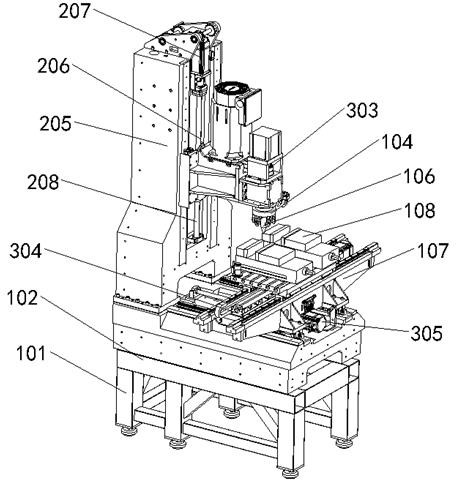

[0047] The first aspect of the present invention provides a temperature measuring device for graphene drilling, including a base 101 and a workbench 102 installed on the base 101 .

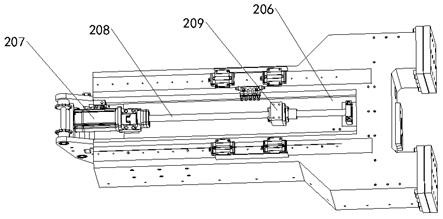

[0048] like figure 1 , 4 , 5, the workbench 102 is provided with a drilling assembly 103 and a temperature measurement assembly 104, the drilling assembly 103 includes a machining spindle 105, a spindle holder 301, a drill 106, an adjustment table 107 and a The clamping device 108 on 107, the temperature measurement assembly 104 includes an annular mounting frame 109, a heat radiation receiver 201, a converter, and a signal processor, and the annular mounting frame 109 is fixedly installed on the processing spindle 105.

[0049] The bottom of the annular mounting bracket 109 is provided with several telescopic rods 202 at intervals in the circumferential direction, and the bottoms of the several telescopic rods 202 are connected with an angle rotation mechanism 203, and the angle rotation mechani...

Embodiment 2

[0063] Another aspect of the present invention provides a temperature measurement method for graphene drilling, such as Image 6 shown, including the following steps:

[0064] S102: collecting the thermal radiation light emitted by different regions of the drill bit or workpiece through several thermal radiation receivers, and obtaining the electrical signal corresponding to the thermal radiation optical signal;

[0065] S104: amplifying and converting the electrical signal to obtain temperature data of different regions of the drill bit or the workpiece;

[0066] S106: Perform fitting analysis on the obtained temperature data to obtain the overall temperature value of the drilling area;

[0067] S108: Cool the drill bit according to the overall temperature value of the drilling area, so that the temperature in the drilling area remains within a certain range;

[0068] S110: Adjust the technological parameters of the drill bit according to the overall temperature value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com