Heavy aromatic oil hydrofining catalyst and method for producing BTX from heavy aromatic oil

A technology for hydrofining and aromatic oil, applied in the fields of hydrofining aromatics, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems affecting BTX yield and catalyst service life, etc. , to achieve the effects of improving comprehensive economy, saving energy consumption, and increasing BTX yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

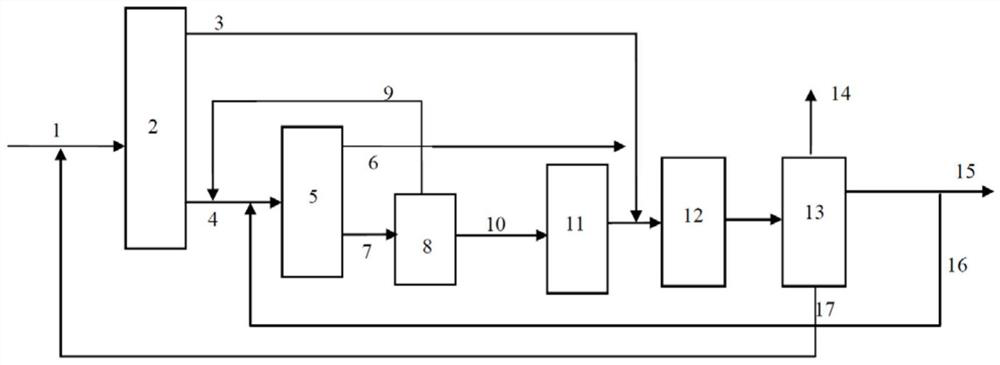

Method used

Image

Examples

preparation example Construction

[0032] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned heavy aromatic oil hydrotreating catalyst, which includes:

[0033] 1) mixing and roasting the natural sponge powder and aluminum hydroxide dry rubber powder to obtain the carrier;

[0034] 2) impregnating the carrier in an impregnating solution, followed by drying and roasting to obtain the heavy aromatic oil hydrofining catalyst, the impregnating solution includes an aqueous solution of a precursor of a metal active component, and the precursor The aqueous solution also contains a nonionic surfactant, wherein the precursor of the metal active component is selected from water-soluble compounds containing metal elements of Group VIB and / or Group VIII.

[0035] In some more specific embodiments, the step 1) specifically includes: drying and pulverizing the natural sponge to obtain a natural sponge powder, then mixing the dry aluminum hydroxide powder with the nat...

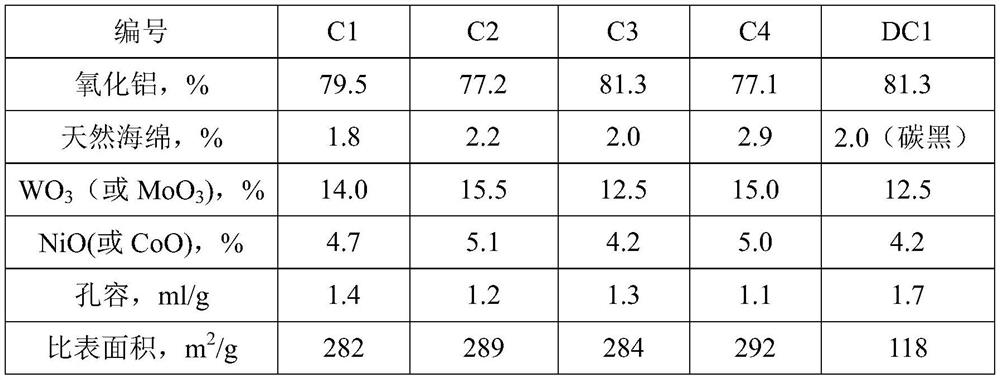

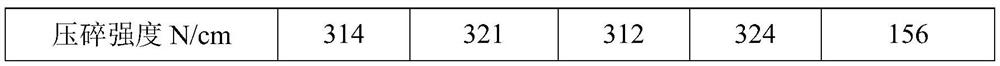

Embodiment 1

[0078] First, 3.0 g of natural sponge is blast-dried, the blower wind speed is 4 m / s, the drying temperature is 55 ° C, the blast drying time is 15 hours, and then pulverized to obtain a natural sponge powder with a particle size of 1500 mesh; Mix well with 160g of aluminum hydroxide dry rubber powder (80% on a dry basis). During the mixing process, add extrusion aids, such as citric acid, in an amount that meets the needs of the carrier; after mixing evenly, the mixture is dried and roasted Get the carrier. The drying temperature is 120° C., and the drying time is 5 hours; the calcination temperature is 500° C., and the calcination time is 1 hour.

[0079] To the prepared tungsten-cobalt impregnation solution, the concentration is 23.0g metal (calculated as oxide, tungsten / cobalt ratio 3:1) / 100mL solution, 100ml in total, add lauryl alcohol polyether, the amount added is based on the total mass of the carrier Add 2% to 10% of the solution to make an aqueous solution, impregn...

Embodiment 2

[0081] First, 3.6g of natural sponge is blast-dried, the blower wind speed is 3 m / s, the drying temperature is 50°C, and the blast drying time is 10h, and then pulverized to obtain a natural sponge powder with a particle size of 1000 mesh; the natural sponge powder is dried at room temperature Mix well with 180g aluminum hydroxide dry rubber powder (dry basis is 70%). During the mixing process, add extrusion aids, such as citric acid, in an amount to meet the carrier molding; after mixing evenly, the mixture is dried and roasted Get the carrier. Wherein the drying temperature is 160°C, and the drying time is 7 hours; the calcination temperature is 400°C, and the calcination time is 15 hours.

[0082] To the molybdenum-cobalt impregnation solution that has been prepared above, the concentration is 26.0g metal (calculated as oxide, molybdenum / cobalt ratio 3:1) / 100mL solution, add 100ml of lauryl alcohol polyether, the amount added is based on the total mass of the carrier Add 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com