Compound digital servo actuator

A digital servo and actuator technology, applied in the direction of servo meter circuit, servo motor assembly, fluid pressure actuator, etc., to achieve the effect of digital control, low cost, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

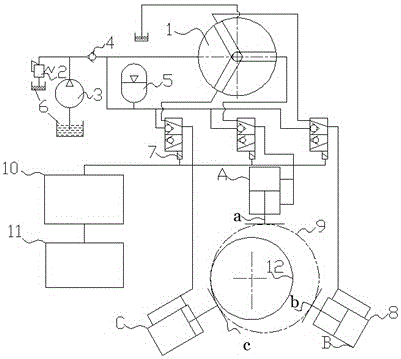

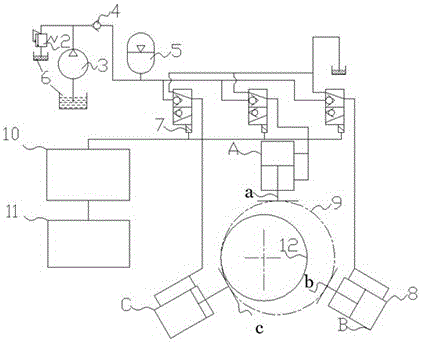

[0029] Such as figure 1 As shown, the actuator is composed of rotary oil distribution valve 1, overflow valve 2, oil pump 3, check valve 4, accumulator 5, oil tank 6, two-position two-way solenoid valve 7, hydraulic cylinder 8, internal meshing gear 9. It is composed of an external meshing pinion 12, a power amplifier 10 and a controller 11.

[0030] figure 1 The middle hydraulic cylinder 8 adopts the form of three hydraulic cylinders distributed on the circumference, and this mechanism can also choose to use the mode of five or seven hydraulic cylinders evenly distributed on the circumference, and its principle remains the same, but the step angle changes. The following takes three hydraulic cylinders as an example to illustrate its working process. After increasing the number of hydraulic cylinders, its working process and principle are the same.

[0031] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com