Three-axis mems inertial sensor system-in-package unit structure

An inertial sensor and system-level packaging technology, which is applied in the direction of navigation through speed/acceleration measurement, can solve the problem that the size and weight are difficult to meet the requirements of miniaturized systems, and cannot meet the high-end inertial sensing field. Consistency and stability are orthogonal Poor compatibility and other issues, to achieve the effect of wide application range, low cost, and submission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, and the following examples are only to illustrate the present invention rather than limit it.

[0022] Package unit structure:

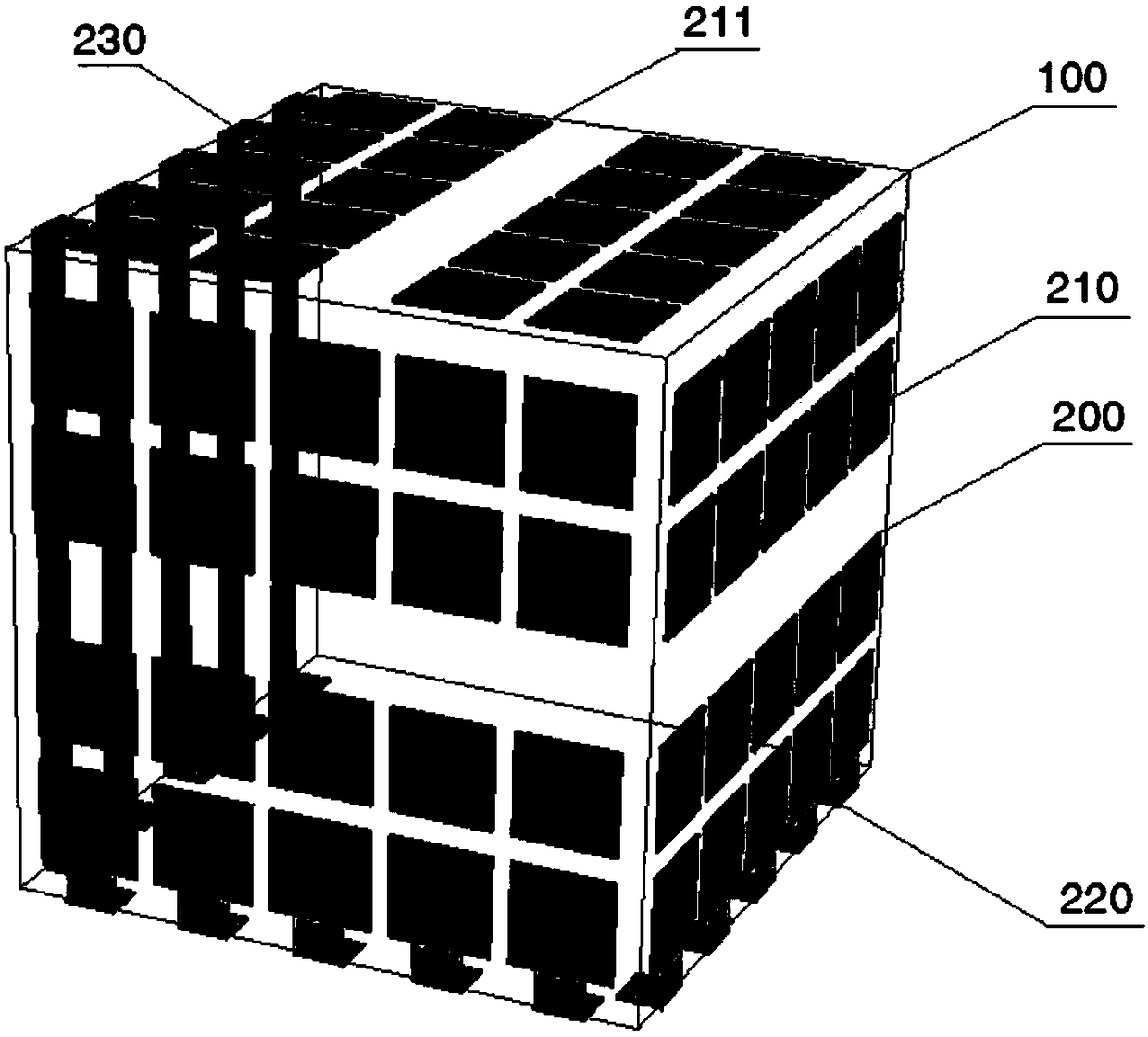

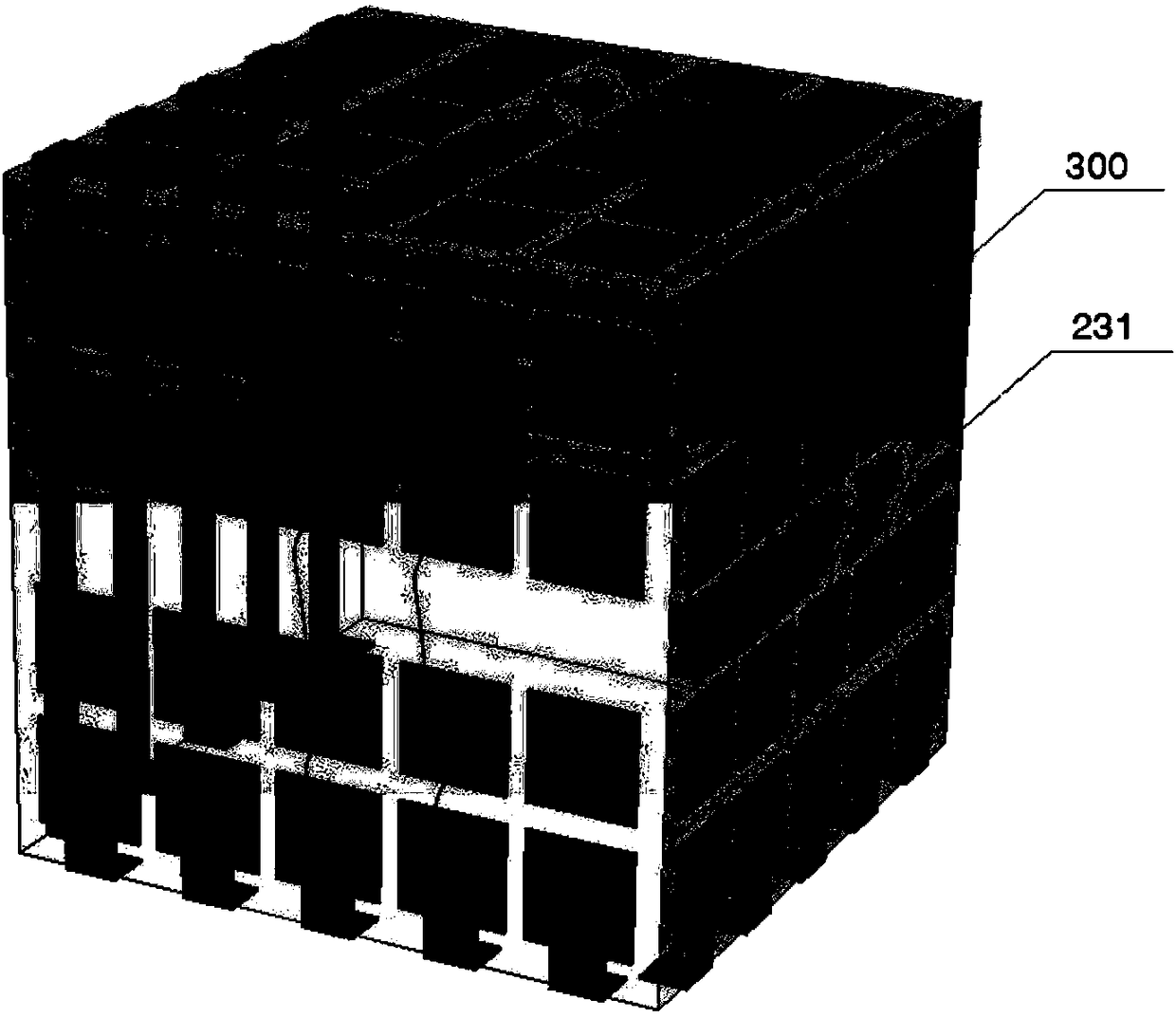

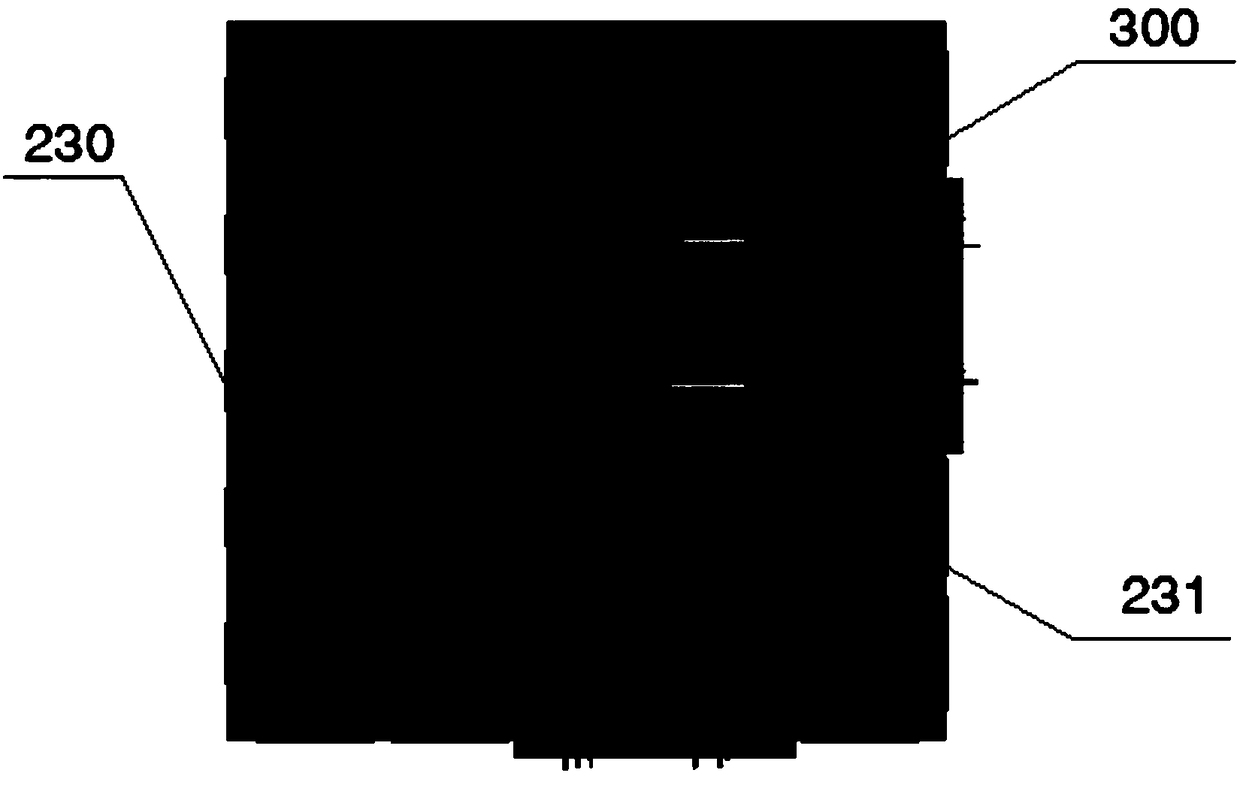

[0023] Such as Figure 1~5 As shown, the three-axis MEMS inertial sensor system-in-package unit structure includes a cuboid (preferably a cube) substrate 100 and a metallization pattern 200 plated on the surface of the substrate 100 for electrical connection. The metallization pattern 200 includes a matrix pattern 210 for soldering on two adjacent side surfaces and the top surface of the substrate 100, a pad 220 provided on the bottom surface of the substrate 100, and a connection pattern 230 for electrically connecting the matrix pattern 210 to the pad 220. . The matrix pattern 210 on each side includes 4*5 (row*column) metallized rectangles 211 . Matrix pattern 210 is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com