Modal test device

A modal test and test bench technology, applied in the testing field, can solve the problems of poor consistency, poor repeatability, high cost, etc., and achieve the effect of convenient and fast test, high efficiency and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below. This embodiment is especially suitable for modal tests of microstructures. The self-contained test bench can solve the excitation problem of microstructures as a whole, such as the modal test of the automatic hammer excitation method of the traveling wave tube. However, the embodiments of the present invention are not limited thereto.

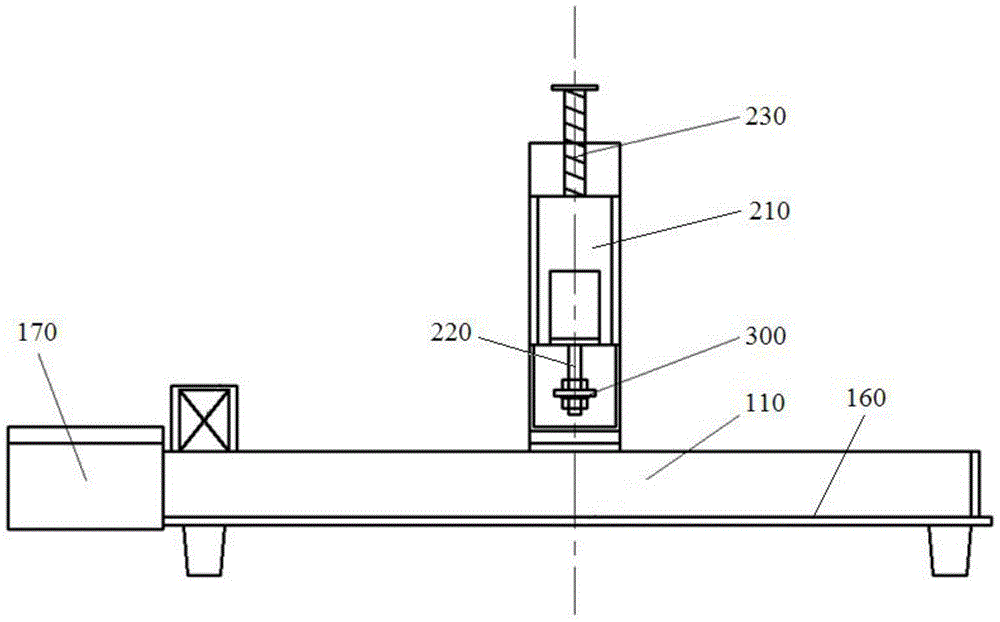

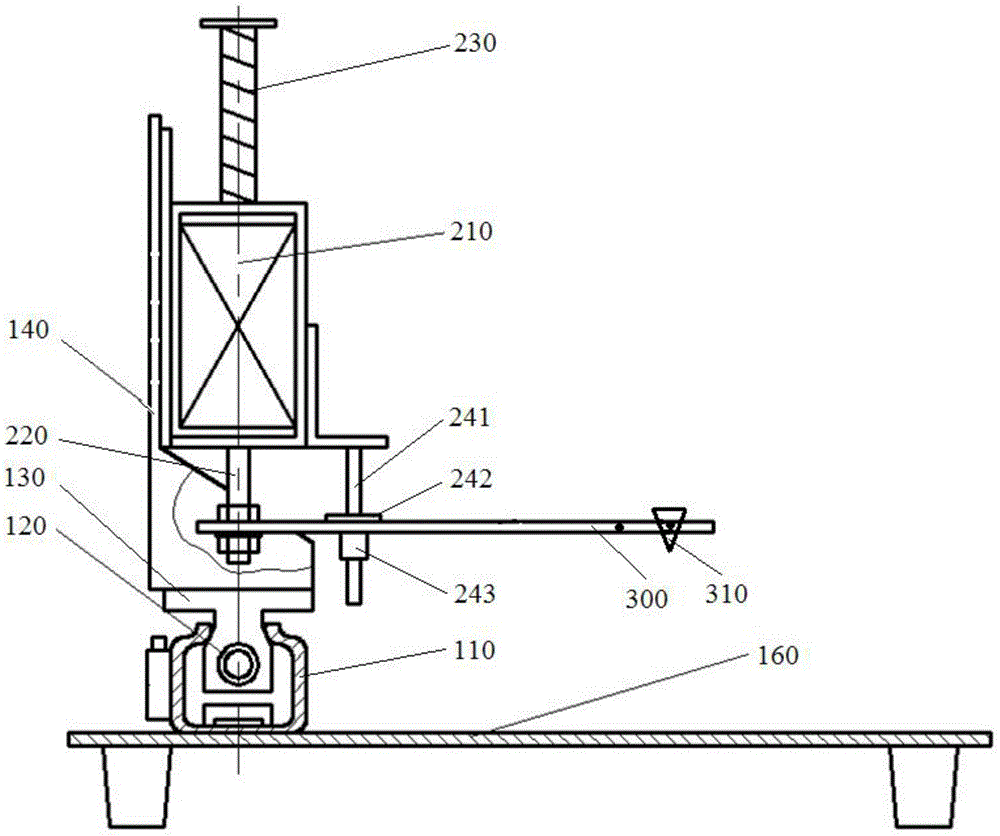

[0022] Such as Figures 1 to 2 As shown, the modal test device includes: a base, a translation mechanism installed on the base, and an excitation mechanism installed on the translation mechanism; wherein, the excitation mechanism includes an exciter, and a hammer handle 300 docked with the exciter, and the hammer handle 300 is provided with a hammer head 310, the hammer head 310 itself is a force-sensing element, or the hammer head 310 is provided with a force-sensing element, for example, the hammer head itself is an integrated force-sensing probe, and the force-sensing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com