Anti-twist device for rotor hub attachment fatigue test

A technology of fatigue test and rotor hub, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of affecting the monitoring of test status, the noise of the test environment, and the inability to apply the force of variable pitch rods, etc. problems, to achieve the effects of improved test efficiency, stable test bench, and small load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below.

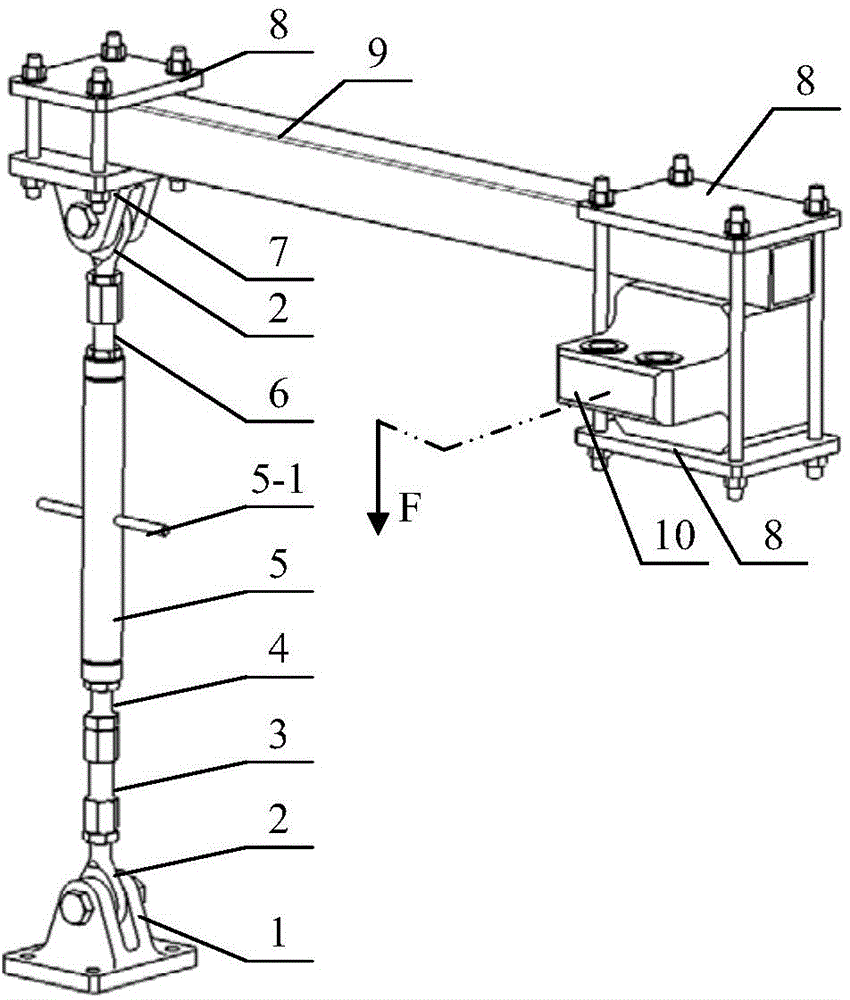

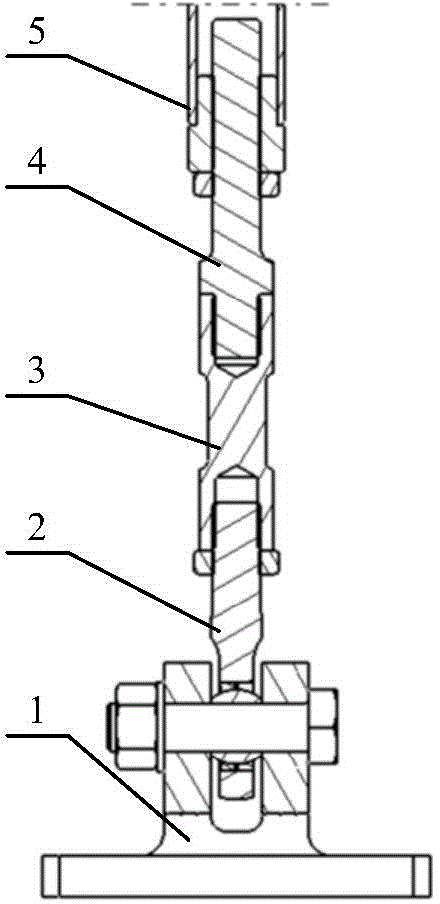

[0018] Such as figure 1 , figure 2 As shown, the present invention is an anti-twist device for a fatigue test of a rotor hub connector, comprising: a fixed support 1, two shank joint bearing assemblies 2, a force measuring rod 3, a left threaded screw joint 4, an adjustment sleeve Pipe assembly 5, right threaded screw joint 6, connecting support 7, compression plate 8, pressure beam 9, simulated paddle root joint 10; fixed end of fixed support 1 is fixedly connected with test bench, fixed support 1 The other end is fixedly connected to one end of a shank joint bearing assembly 2, and one end of the force measuring rod 3 is connected to the other end of the shank joint bearing assembly 2; the other end of the force measuring rod 3 is connected to one end of the left threaded screw joint 4; The other end of the left threaded screw joint 4 is connected to one end of the adjustment sleeve assembly 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com