Airfoil robust optimization design method based on non-probability interval analysis model

A technology of interval analysis and design method, which is applied in gene models, calculations, instruments, etc., and can solve the problems of poor robustness and low efficiency of optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, design examples of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the selected examples are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

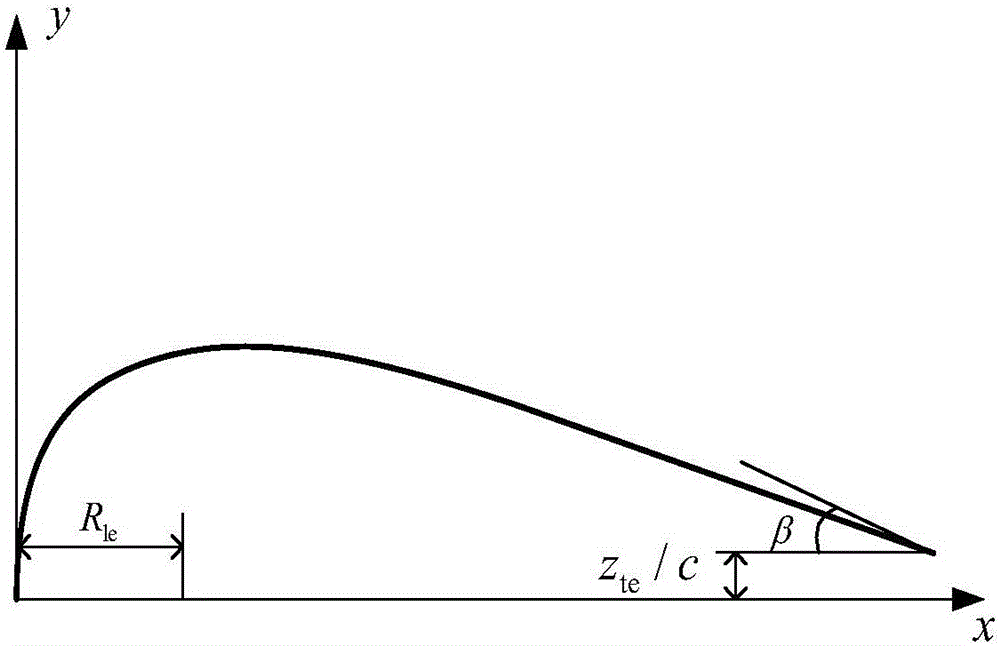

[0058] (1) With the NACA0012 airfoil as the initial airfoil, use the type function / shape function conversion CST method to set the expression of the parameterized airfoil curve, and the geometric meaning of some parameters is as follows figure 1 shown.

[0059] (2) Extract the geometric parameters in the CST method as optimal design variables, and the value ranges of each optimal variable are shown in Table 3:

[0060] Table 3 Value range of airfoil optimization design variables

[0061]

[0062] (3) The Mach number Ma of the future flow is used as an uncertain design parameter, its interval is Ma∈[0.74,0.76], and the center value is Ma c =0.75, the interval radius is ΔMa=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com