Spraying system for waste gas purifying tower

A spray system and exhaust gas purification technology, applied in chemical instruments and methods, use of liquid separators, dispersed particle separation, etc., can solve the problems of small pipe nozzle flow and spray area, easy clogging of pipe nozzles, and large number of nozzles. , to achieve the effect of easy mass production, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

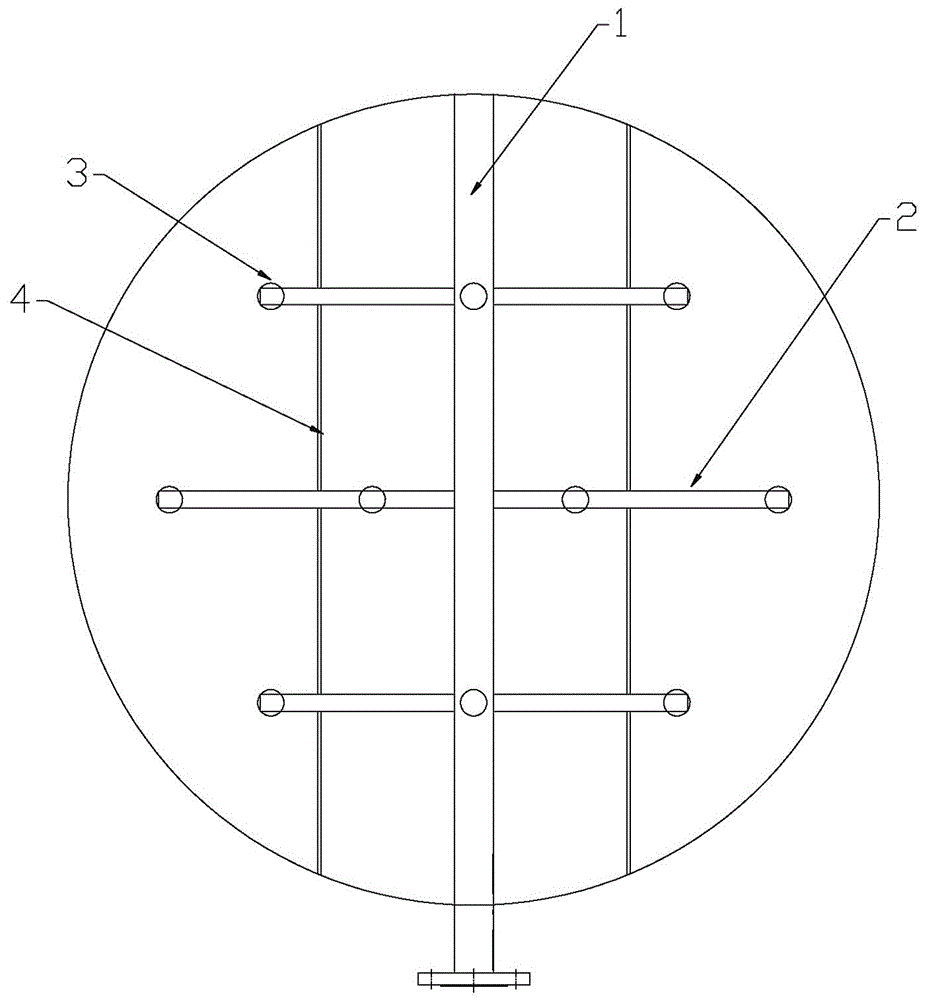

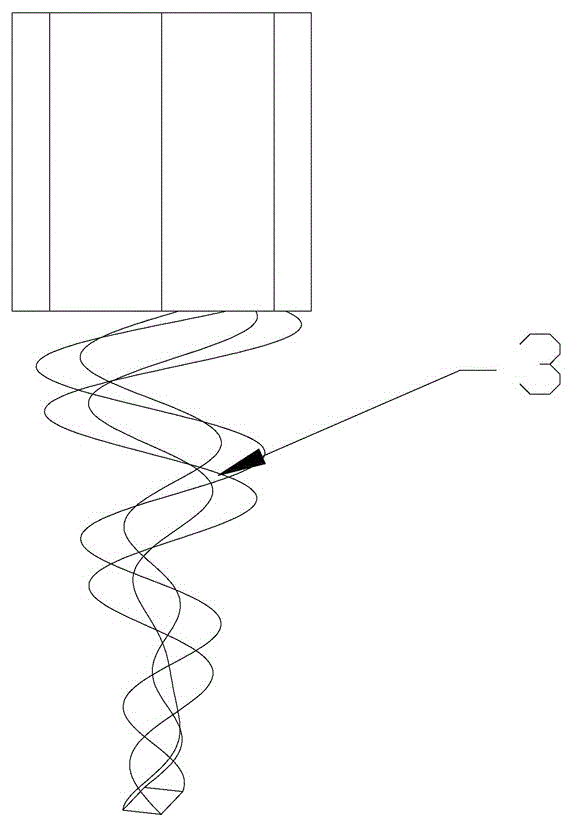

[0015] Such as Figure 1-2 Shown: a spraying system for exhaust gas purification tower, including spraying main pipe 1, spraying branch pipe 2 is evenly erected on spraying main pipe 1, and in order to strengthen the stability of spraying branch pipe 2, spraying branch pipe 2 Supported by a flat steel frame 4; 2-4 spiral nozzles 3 are uniformly arranged at the bottom of the spray branch pipe 2, and the water flow entering the spiral nozzle 3 from the spray branch pipe 2 passes through the layered interface of the spiral to produce a layered spray, the above The spiral nozzle 3 is made by injection molding, casting or kiln sintering.

[0016] In the present invention, the spiral nozzle 3 is evenly arranged at the bottom of the spray branch pipe 2. Since the interior of the spiral nozzle 3 has no structure, it is a smooth passage, a typical impact-type d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com