Calculation method for radiating and ventilating air speed of main transformer chamber of transformer substation

A calculation method and the technology of the main transformer room, which are applied in the field of power transmission and distribution, can solve the problems of reduced design ventilation, noise pollution, and low ventilation volume, so as to improve the ventilation volume, ensure normal operation, and overcome the problems of low estimation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical scheme of the present invention, the inventors of the present invention will describe in detail below through specific examples:

[0017] A method for calculating the heat dissipation ventilation wind speed of a substation main transformer room of the present invention comprises the following steps:

[0018] Step 1. The main sources of heat in the main transformer room include the following four items: the heat converted by the reactive power loss of the main transformer, the heat generated by the fully insulated copper tube busbar under the working current, and the heat transfer to the main transformer room under the combined effects of outdoor air temperature and sunshine 1. Calculate the calorific value of the lighting fixtures in the main transformer room, and estimate the calorific value in the main transformer room. The calorific value is about 0.30-0.37% of the rated capacity of the main transformer.

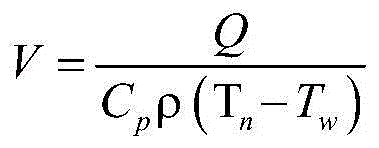

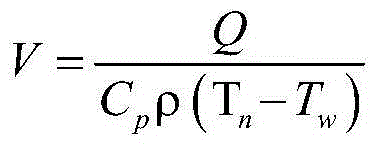

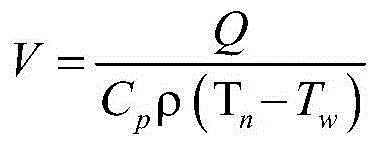

[0019] Step 2. Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com