Method for preparing white LED

A technology of white light and white glue, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven color of white light and blue light leakage of chips, and achieve the effect of uniform and saturated white light color, low cost and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the preparation method of a white light LED chip provided by the present invention, a specific preparation process thereof will be described below. This embodiment adopts the following steps:

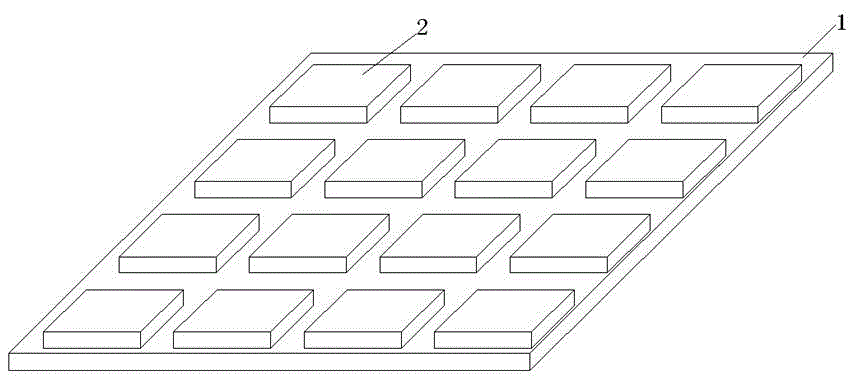

[0018] (1) Die bonding: first fix the flip-chip LED chip 2 on the substrate 1 arranged in an array with flux (such as figure 1 As shown), the substrate 1 is provided with electrical connection lines; then the substrate after die bonding is baked by reflow soldering at a baking temperature of 150°C and a baking time of 8 minutes;

[0019] (2) Paste a fluorescent film on the surface of the LED chip 2, mix the silica gel main agent, curing agent and yellow fluorescent powder in the fluorescent film in a weight ratio of 1:2:0.24, and stir evenly to form a fluorescent film; The excitation wavelength of the yellow phosphor is 560nm;

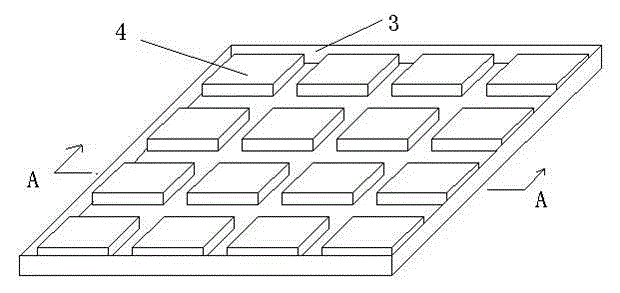

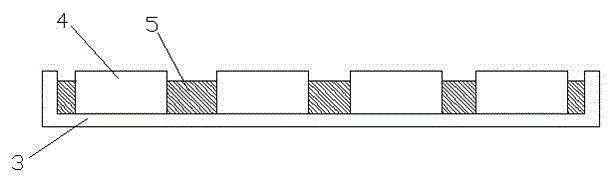

[0020] (3) White glue coating and curing: make a mold 3 corresponding to the substrate 1, such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com