White-light LED chip packaging structure and manufacturing method thereof

A technology of LED chip and packaging structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc. It can solve the problems of blue light leakage around the chip, the utilization rate of light has not been effectively improved, and the color of white light is uneven, so as to improve the welding yield. , It is convenient to polish the electrode and avoid the effect of blue light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

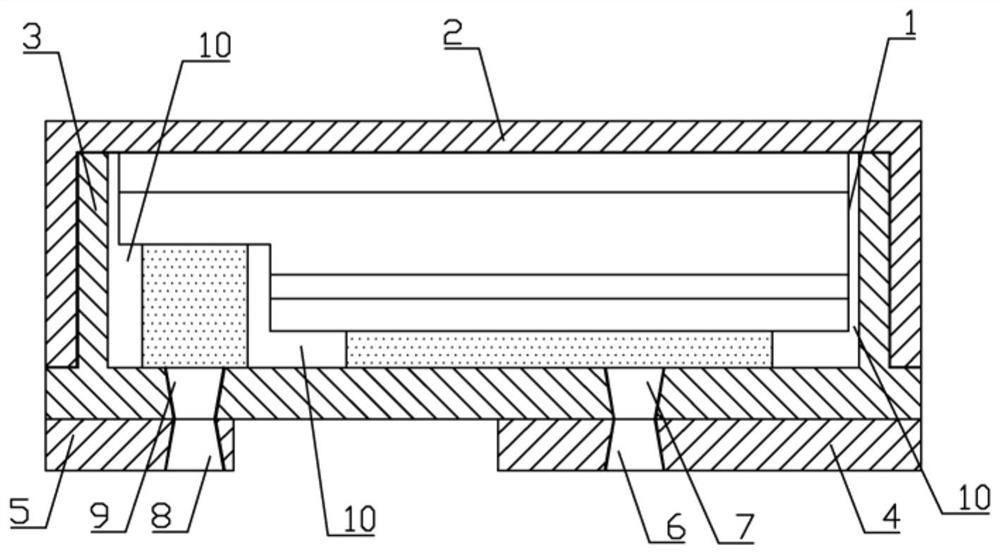

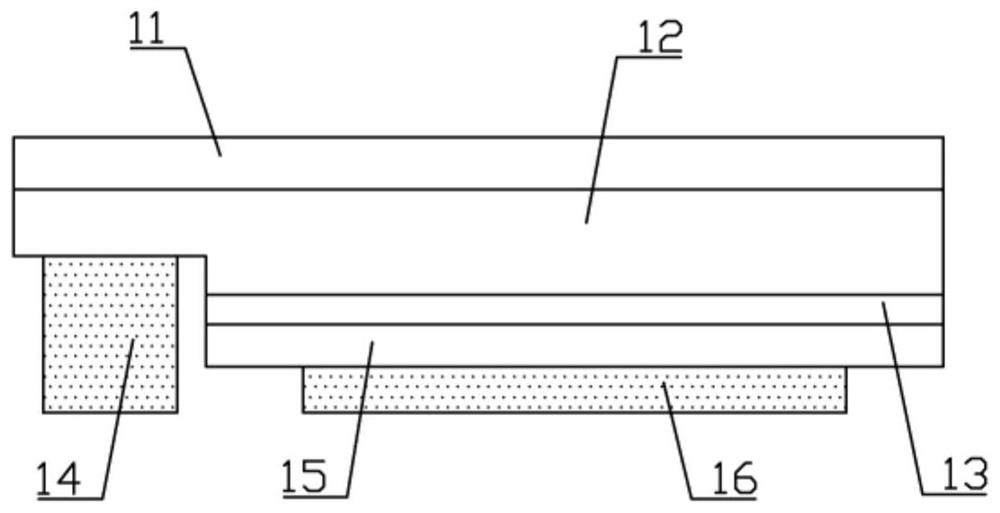

[0033] Such as figure 1 and to figure 2 As shown, a packaging structure of a white LED chip includes a blue LED chip 1, a fluorescent shell 2 for converting light color and a high-reflection white plastic shell 3. The reflective white plastic shell 3 is embedded in the fluorescent shell 2 and forms a closed space with the fluorescent shell 2. The blue LED chip 1 is packaged in the closed space. The LED blue light chip 1 includes a substrate layer 11 and N-type GaN grown on the front surface of the substrate layer 11. Layer 12, the light-emitting layer 13 grown on the front side of the N-type GaN layer 12, the N-type conductive layer 14 grown on the front side of the N-type GaN layer 12, the P-type GaN layer 15 grown on the front side of the light-emitting layer 13, and the P-type GaN layer grown on the front side of the P-type GaN layer. The P-type conductive layer 16 on the front side of the GaN layer 15; the outer bottom surface of the highly reflective white plastic shell...

Embodiment 2

[0041] A method for manufacturing a white light LED chip packaging structure, comprising the following steps:

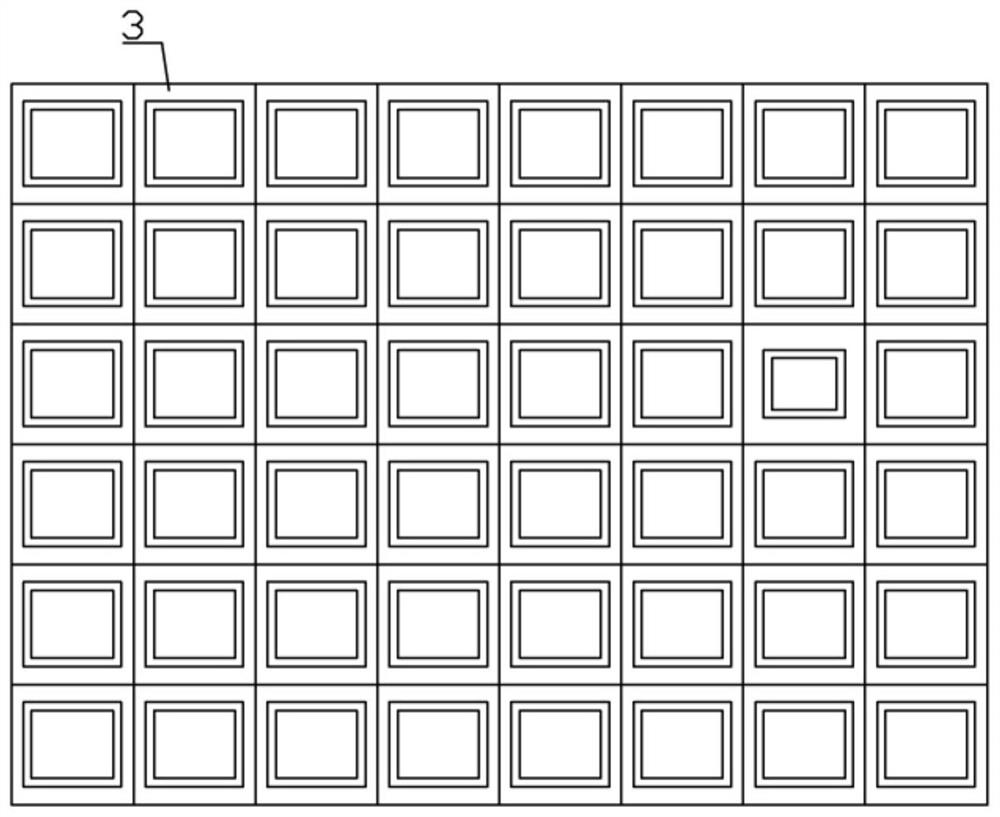

[0042] S1, such as image 3 As shown, make a highly reflective white plastic case 3;

[0043] S2, such as Figure 4 As shown, make a fluorescent shell 2 for converting light color;

[0044] S3, such as Figure 5 As shown, the P-type electrode 4 and the N-type electrode 5 are attached to the outer bottom surface of the high-reflection white plastic shell 3 respectively, and the P-type electrode 4 and the outer bottom surface of the high-reflection white plastic shell 3, the N-type electrode 5 and the high-reflection white plastic shell 3 are made respectively. The through hole on the outer bottom surface of the white plastic shell 3;

[0045] S4, such as Image 6 As shown, the blue LED chip 1 is inverted in the highly reflective white plastic shell 3, and the transparent epoxy resin 10 is filled in the gap between the fluorescent shell 2 and the blue LED chip 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com