A kind of preparation method of white light LED chip

An LED chip, white light technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems such as the utilization rate of light has not been effectively improved, with yellow or blue light spots, LED chips can not reach, etc. Light utilization, small light-emitting angle, uniform spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment adopts the following steps:

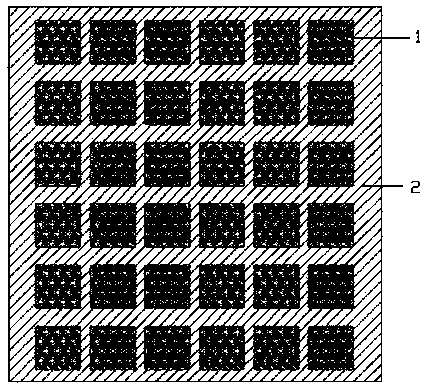

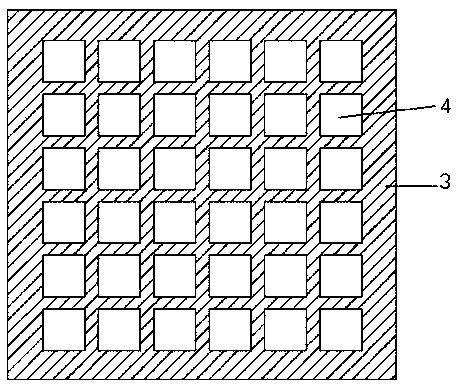

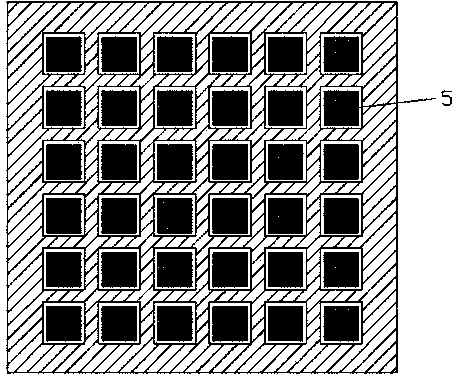

[0017] Prepare the mold: eg figure 1 In the mold shown, the shaded part is raised upwards, and the raised height is the same as the height of the flip chip. The length and width of the raised part are slightly larger than the LED chip; prepare high-reflective white glue; preheat the mold, figure 1 The concave part of the mold shown is evenly sprayed with release agent; figure 1 As shown, apply the high-reflective white glue slurry on the side of the mold sprayed with film release agent, and the resin scraper moves at a speed of 0.1-5mm / s. The speed of the scraper is controlled by the motor and the cylinder, and the white glue and the mold Scrape to the same plane; transfer the mold to a high-temperature oven and bake at 100-200°C for 30-200 minutes; figure 2 As shown in the transfer film tool, place the remaining high-reflective white plastic screen frame on the high-temperature resistant high-temperature film or UV film;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com