Method And Apparatus To Determine An Effective Temperature Of Coolant Fluid For A Heat Generating Device

A fluid temperature and heating device technology, applied in the temperature field, can solve problems such as reducing motor torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

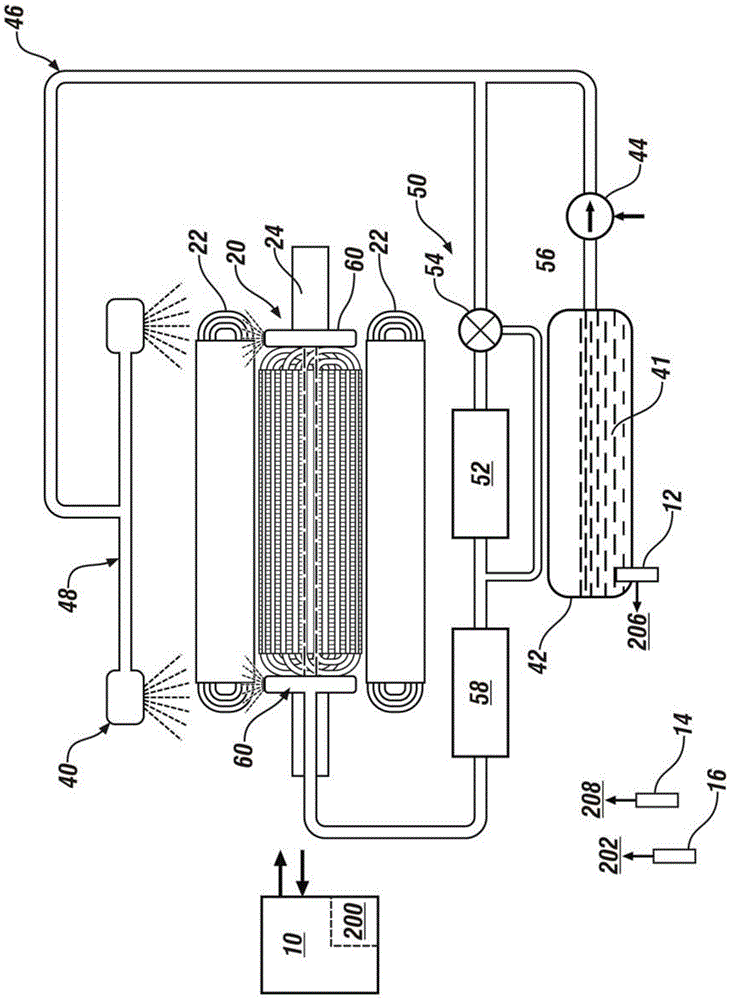

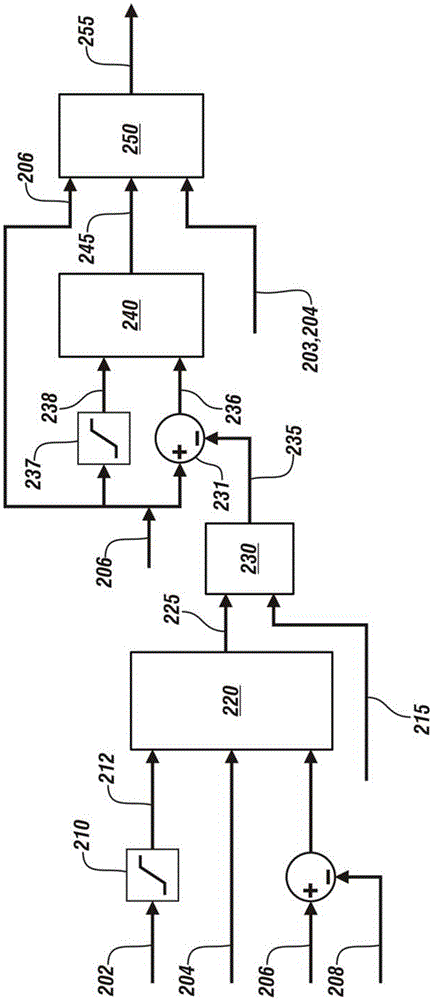

[0018] Referring now to the drawings, in which the description is for the purpose of illustrating certain particular embodiments only and not for the purpose of limiting them, figure 1 Elements of an electrically driven motor / generator (electrical machine) 20 , associated cooling / lubrication system 40 and controller 10 executing a control routine 200 are schematically shown. As described herein, the electric machine 20 is used to generate traction on the vehicle, although the invention is not so limited. The motor 20 is an example of a heat generating device. Other heat generating devices employing embodiments of the controller 10 and associated cooling / lubrication system 40 executing the control routine 200 may be considered within the scope of the present invention.

[0019] The electric machine 20 includes a stator 22 and a coaxial rotor 24, and may be any suitable electric machine, such as an asynchronous motor or a synchronous motor. In one embodiment, electric machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com