Permanent magnet torque converter

A torque converter and permanent magnet technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve problems such as wear environment, reduce the size of the transmitted torque, and increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

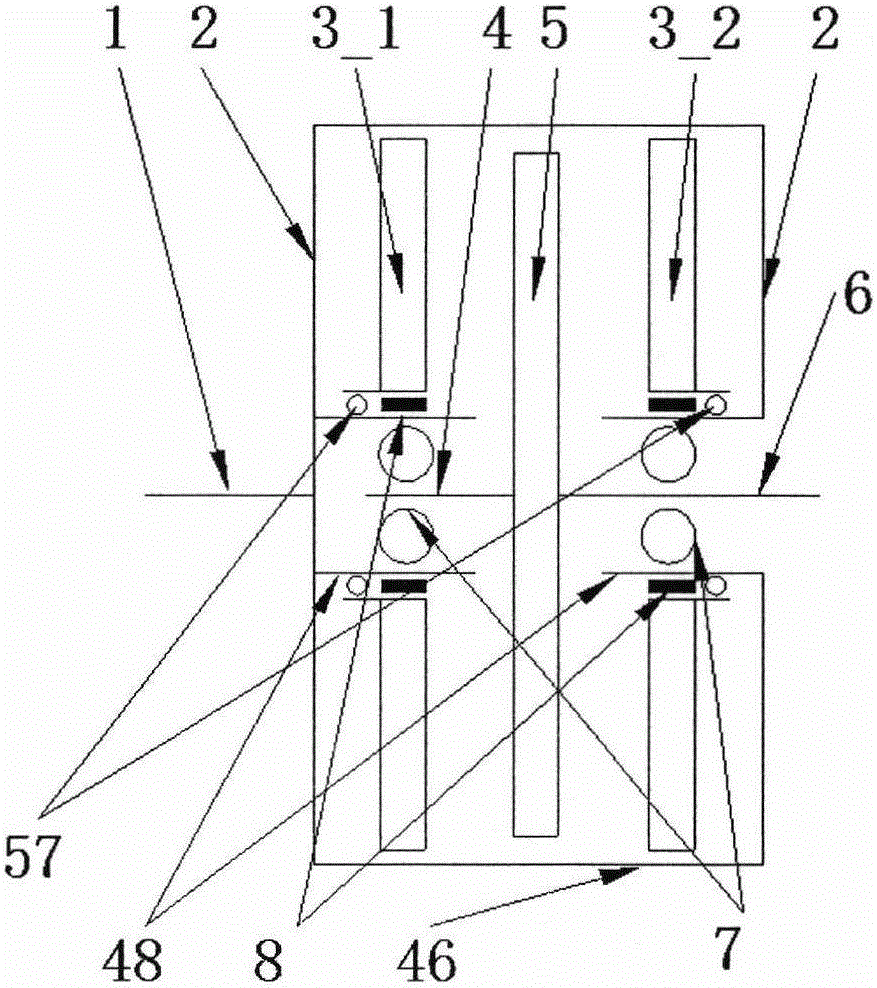

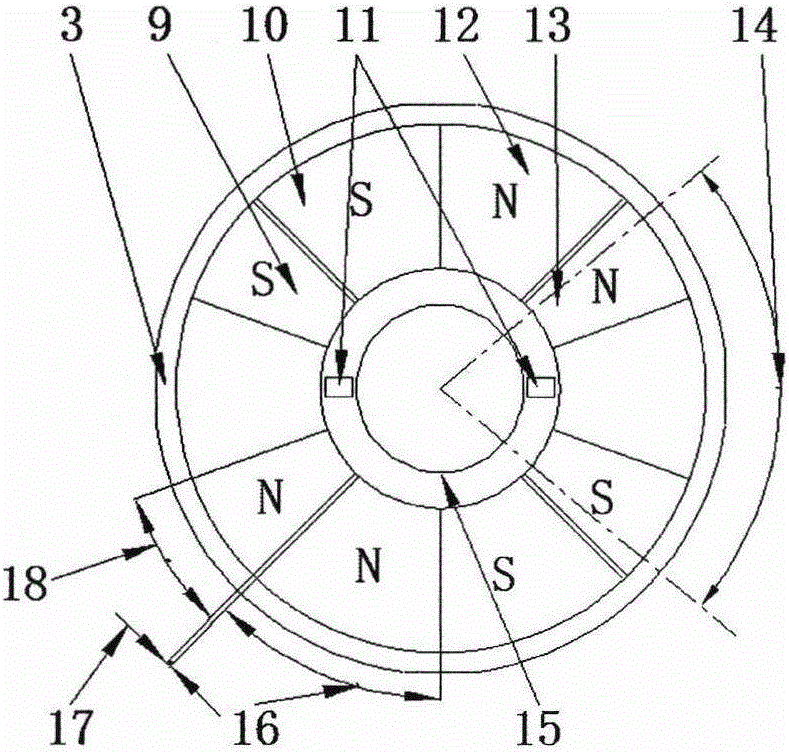

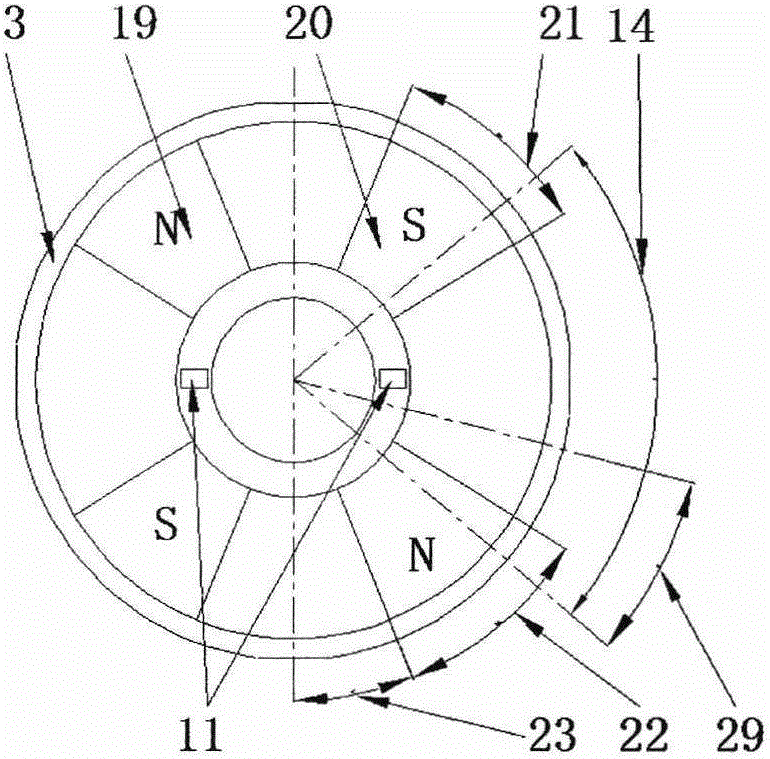

[0025] Refer to attached figure 1 - attached Figure 13, a permanent magnet torque converter is characterized in that: the input shaft 1 is coaxially connected to the disk frame 2, the diameter of the disk frame 2 is 260mm, the diameter of the complex disk 3 is 235mm, and the complex disk 3 is equipped with a positive fan-shaped main magnet 10. Forward secondary magnet 9, reverse sector-shaped main magnet 12 and reverse sector-shaped secondary magnet 13, the inner diameter of the forward sector-shaped main magnet 10 is 100 mm, the outer diameter is 220 mm, and the sector angle is 42°. Sector-shaped auxiliary magnet 9 has an inner diameter of 100mm, an outer diameter of 220mm, and a sector angle of 20°. The inner diameter of the reverse sector-shaped main magnet 12 is 100mm, an outer diameter of 220mm, and a sector angle of 42°. The reverse sector-shaped secondary magnet 13 The inner diameter is 100mm, the outer diameter is 220mm, and the sector angle is 20°. There are 8 perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sector angle | aaaaa | aaaaa |

| Sector angle | aaaaa | aaaaa |

| Sector angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com