Processing method for surface of workpiece using rotating cutting tool

一种切削工具、加工方法的技术,应用在用于产生装饰表面效果的工艺、制造工具、机械表面处理等方向,能够解决刀痕不足装饰花纹焕发美观等问题,达到提高美观的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

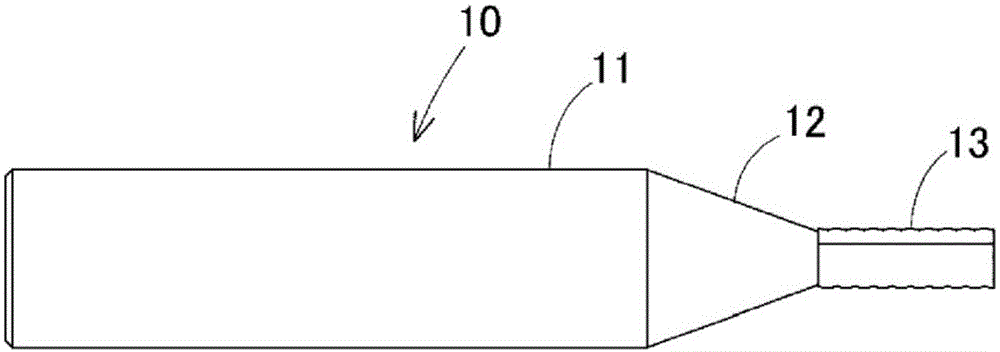

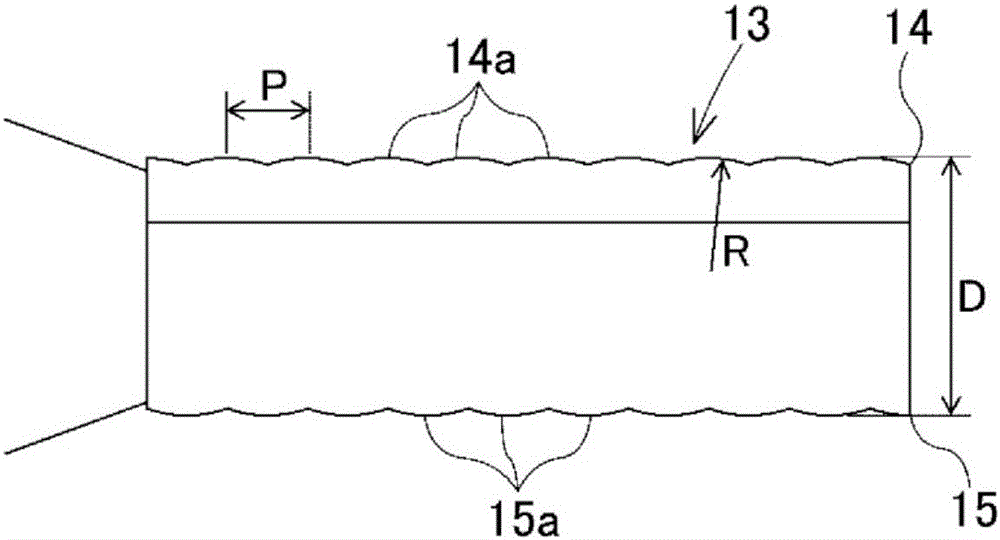

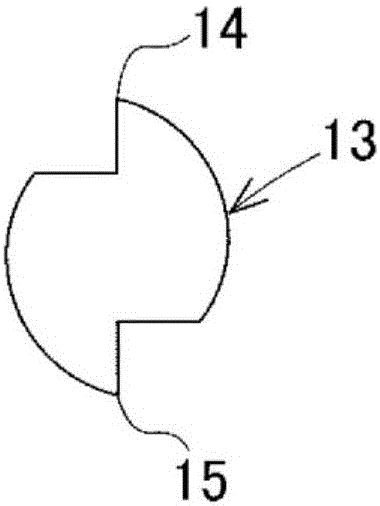

[0070] Embodiments of the present invention will be described below using the drawings. figure 1 A rotary cutting end mill (hereinafter referred to as an end mill) 10 according to Example 1 is shown in front view, Figure 2A , Figure 2B The main body 13 of the end mill 10 is shown in an enlarged front view as well as in an enlarged side view. The end mill 10 is coaxially provided with a small-diameter body 13 at the end of a large-diameter shank 11 via a connecting portion 12 , and is provided at two positions spaced apart at equal intervals in the circumferential direction of the outer periphery of the body 13 and extends in the direction of the rotation axis. A pair of cutting edges 14,15. That is, the number Z of cutting edges of the end mill 10 is two. The cutting edges 14, 15 are continuously formed with a plurality of split edges 14a, 15a at the same pitch P (same length) in the rotation axis direction. The cutting edges of the split blades 14a and 15a have an arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com