Potato planting machine

A potato planter and rack technology, applied in the field of agricultural machinery, can solve the problems of low ditching efficiency, single structure of seeding openers, low efficiency, etc., and achieve the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

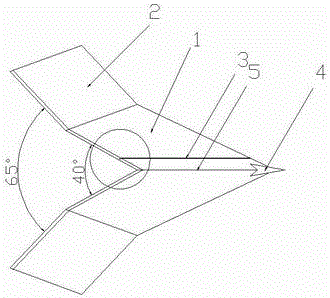

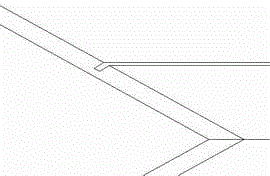

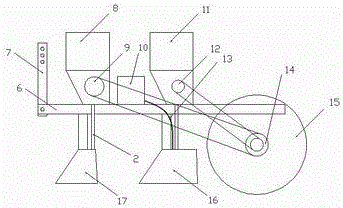

[0016] The specific implementation of the present invention is explained below.

[0017] Such as figure 1 Shown, a kind of potato planting machine comprises frame 6; Be arranged on the fertilizer box 8 on the frame, be arranged on the fertilizer device in the fertilizer box, the fertilizer device sprocket wheel 9; Seed material box 11, be arranged on seed material Seed metering device in the box, seed metering device sprocket wheel; Water tank 10 and water pipe 13; Ground wheel 15; The fertilizer and the fertilizer sprocket of the fertilizer discharger are installed in the fertilization box. The fertilizer discharger includes a fertilizer shaft. The top of the fertilizer discharger in the fertilizer discharge box is a funnel-shaped structure. The box first falls into the fertilizer groove of the fertilizer shaft through the funnel-shaped structure, and the fertilizer shaft rotates under the drive of the sprocket of the fertilizer discharger. The fertilizer in the fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com