Cutting blender mixer used for hay automatic discharging, pressing and filtering

An automatic unloading and mixing machine technology, applied in cutting equipment, applications, agricultural machinery and implements, etc., can solve the problems of affecting work and different lengths of forage, and achieve the effect of improving efficiency, improving collection efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

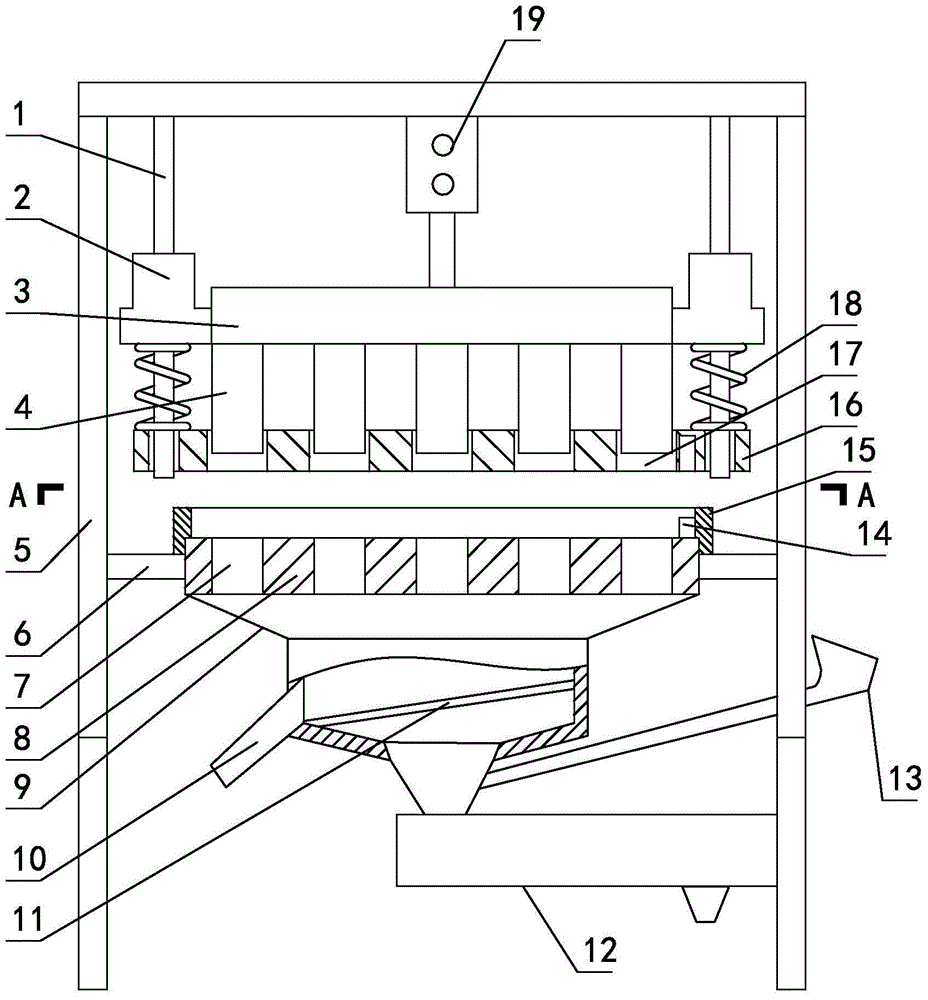

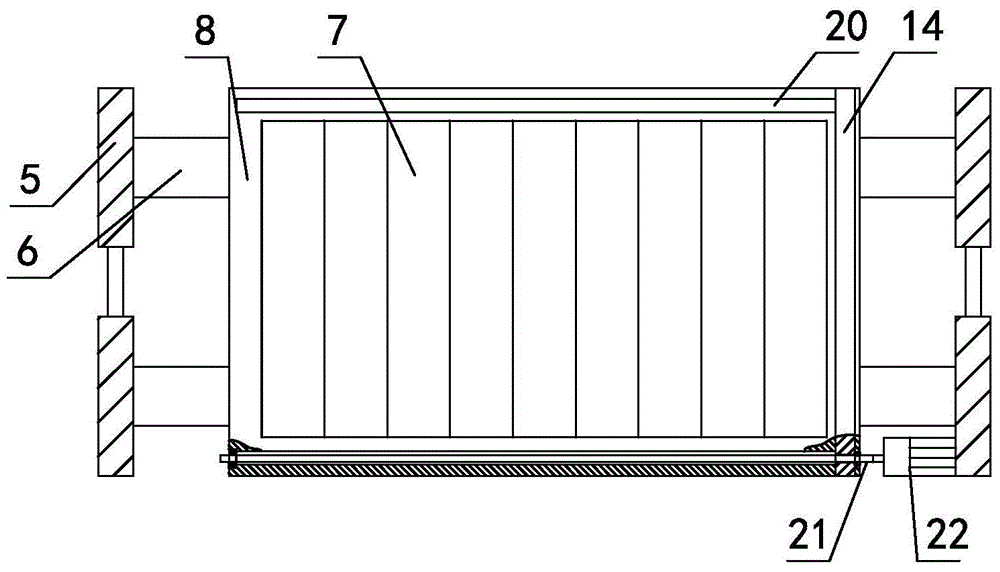

[0024] like figure 1 , figure 2 As shown, the cutting and mixing machine for automatic unloading, pressing and filtering of forage includes a support 5 with a door-type structure as a whole, and a moving knife and a static knife for mutual cutting and cooperation are sequentially arranged in the support 5 from top to bottom. The moving knife includes a knife seat 3, several cutter heads 4 are installed at the bottom of the knife seat 3, the top of the knife seat 3 is connected with a power mechanism 19 for the up and down movement of the knife seat 3, the power mechanism 19 is fixed on the top of the support 5, and the static knife includes a static Knife plate 8, on the static knife plate 8, there is a knife hole 7 that communicates up and down and cuts with the cutter head 4. The static knife plate 8 is arranged on the support 5, and the top of the static knife plate 8 is provided with a The slide plate 14 that slides left and right on the surface, the front and rear lengt...

Embodiment 2

[0028] A further change is made on the basis of the first embodiment, the power mechanism 19 is changed into an air cylinder, the cylinder body of which is fixed on the bracket 5 , and the piston rod is connected to the tool seat 3 . Others are the same as embodiment one.

Embodiment 3

[0030] Further changes are made on the basis of Embodiment 1, and the power mechanism 19 is changed. The power mechanism 19 includes a screw and a nut that cooperate with each other. Only free rotation can be done on the support 5, and the nut is driven by a gear set. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com