Visible light-based flue gas mercury removal method and circular spraying-type mercury removal device employing same

A visible light and mercury removal technology, applied in the field of environmental pollution prevention and control, can solve the problems of increasing the commercial value of fly ash, large flow resistance of flue gas, and inconspicuous removal effect, so as to improve the efficiency of flue gas purification, reduce costs, reduce smoke The effect of gas cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

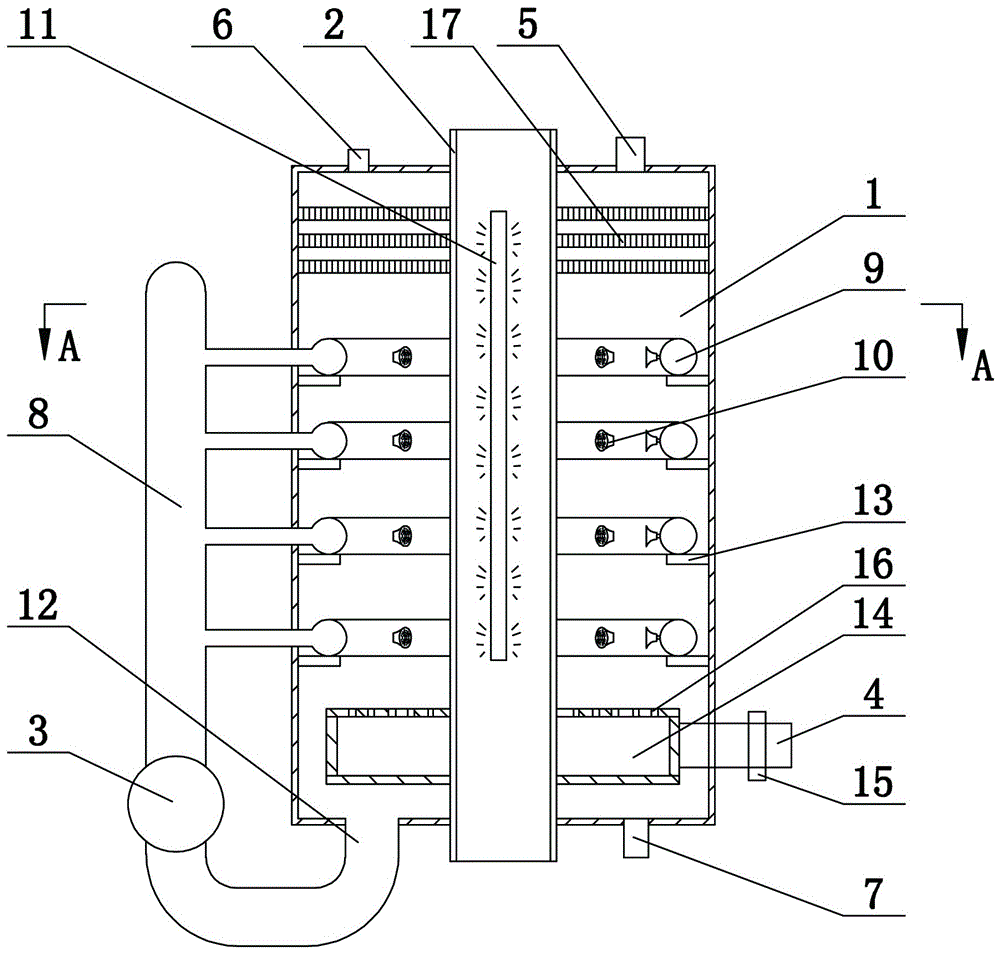

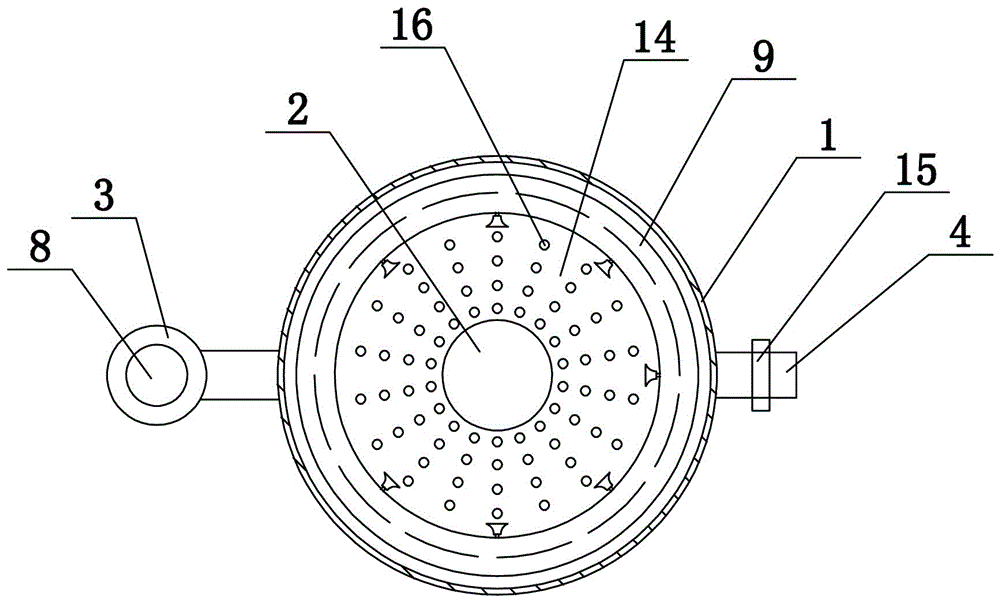

[0040] Such as figure 1 , figure 2 As shown, a ring spray mercury removal device for flue gas mercury removal based on visible light includes a reactor 1, a central quartz glass tube 2, a circulation pump 3, an air intake pipe 4, an exhaust port 5, a liquid inlet 6, Liquid discharge port 7, circulation pipe 8, ring nozzle pipe 9 and sprinkler head 10, the bottom of the reactor 1 is connected to the inlet pipe 4, the bottom of the reactor 1 is provided with an air distribution box 14, and the air distribution box 14 is connected to the inlet pipe 4 to enter A one-way valve 15 is arranged on the air pipe 4, and an air distribution hole 16 is evenly arranged on the top plate of the air distribution box 14, and the central quartz glass tube 2 is installed in the reactor 1, and the central quartz glass tube 2 is connected with the reaction vessel. The reactor 1 is sealed and tightly connected, the central quartz glass tube 2 is provided with a visible light source 11, the reactor...

Embodiment 2

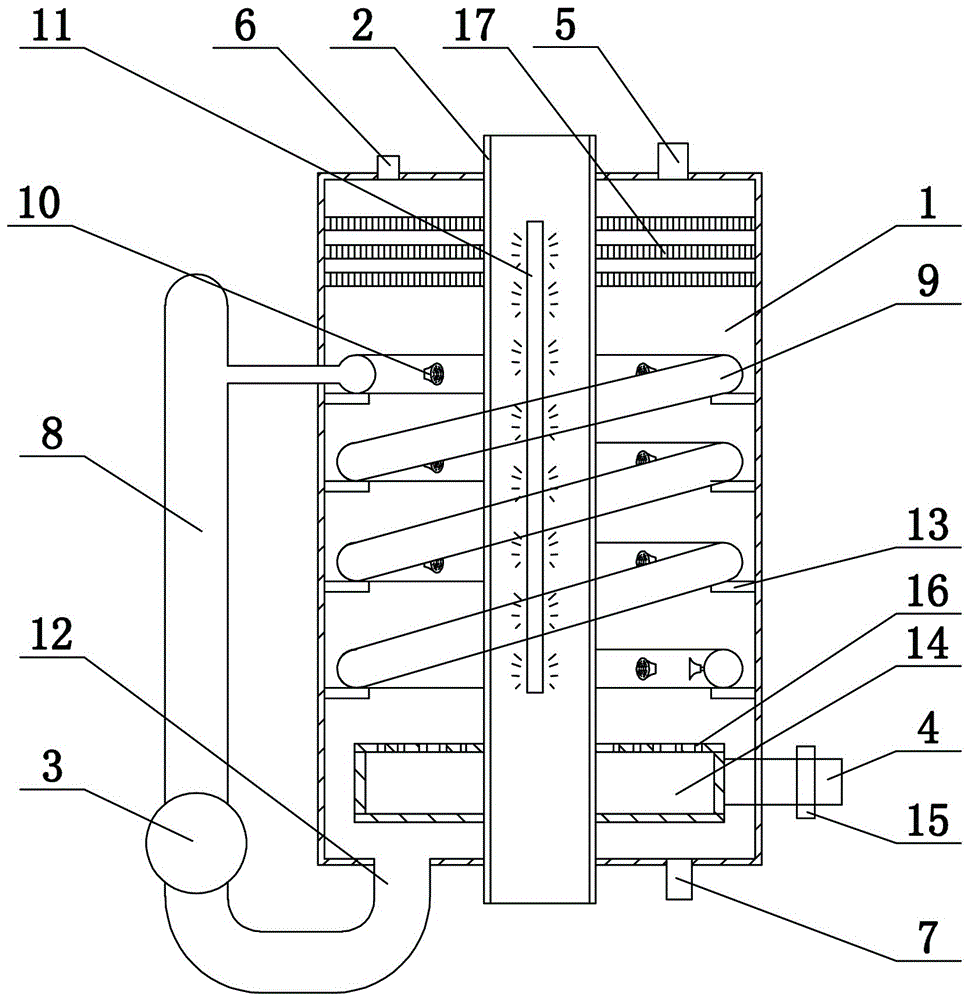

[0064] Such as image 3 As shown, repeating Example 1, there are the following differences, the ring nozzle 9 is centered on the central quartz glass tube 2 and spirally wound on the inner wall of the reactor 1 from top to bottom, and the ring nozzle 9 is evenly arranged with multiple 10 sprinkler heads. The inner wall of the reactor 1 is spirally provided with a support plate 13 , the ring nozzle 9 is placed on the support plate 13 , and the support plate 13 supports the ring nozzle 9 .

[0065] This embodiment adopts composite catalyst The method for removing mercury from coal-fired flue gas is as follows:

[0066] 1. Catalyst preparation

[0067]1) Add 50-350 ml of glacial acetic acid into 0-300 ml of deionized water, stir evenly for 10-30 minutes, add 0.16 mol of KI, stir magnetically for 20-60 minutes, add 0.08 mol of bismuth nitrate and 0.08 mol of silver nitrate to obtain the catalyst Solution, denoted as A solution;

[0068] 2) Add 50-350 ml of glacial acetic a...

Embodiment 3

[0082] Repeat Example 1, with the following differences:

[0083] This embodiment adopts composite catalyst The method for removing mercury from coal-fired flue gas is as follows:

[0084] 1. Catalyst preparation

[0085] 1) Add 50-350 ml of glacial acetic acid into 0-300 ml of deionized water, stir evenly for 10-30 minutes, add 0.18 mol of KI, stir magnetically for 20-60 minutes, add 0.09 mol of bismuth nitrate and 0.09 mol of silver nitrate to obtain the catalyst Solution, denoted as A solution;

[0086] 2) Add 50-350 ml of glacial acetic acid into 0-300 ml of deionized water, stir evenly for 10-30 minutes, add 0.02mol of KBr, stir magnetically for 20-60 minutes, add 0.01mol of bismuth nitrate and 0.01 mol of silver nitrate to obtain visible light catalyst Solution, denoted as B solution;

[0087] 3) Under magnetic stirring, mix solution B with solution A, stir magnetically for 20 to 60 minutes, let it stand for 5 to 10 hours, then place it under a 60 to 150 watt ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com