A high-temperature flue gas mercury removal device and process

A technology for high-temperature flue gas and mercury removal, which is applied in combined devices, gas treatment, gaseous effluent wastewater treatment, etc., can solve the problems of high equipment investment, high cost of activated carbon, and unfavorable industrial applications, so as to avoid resource waste and improve condensation. and effect, the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

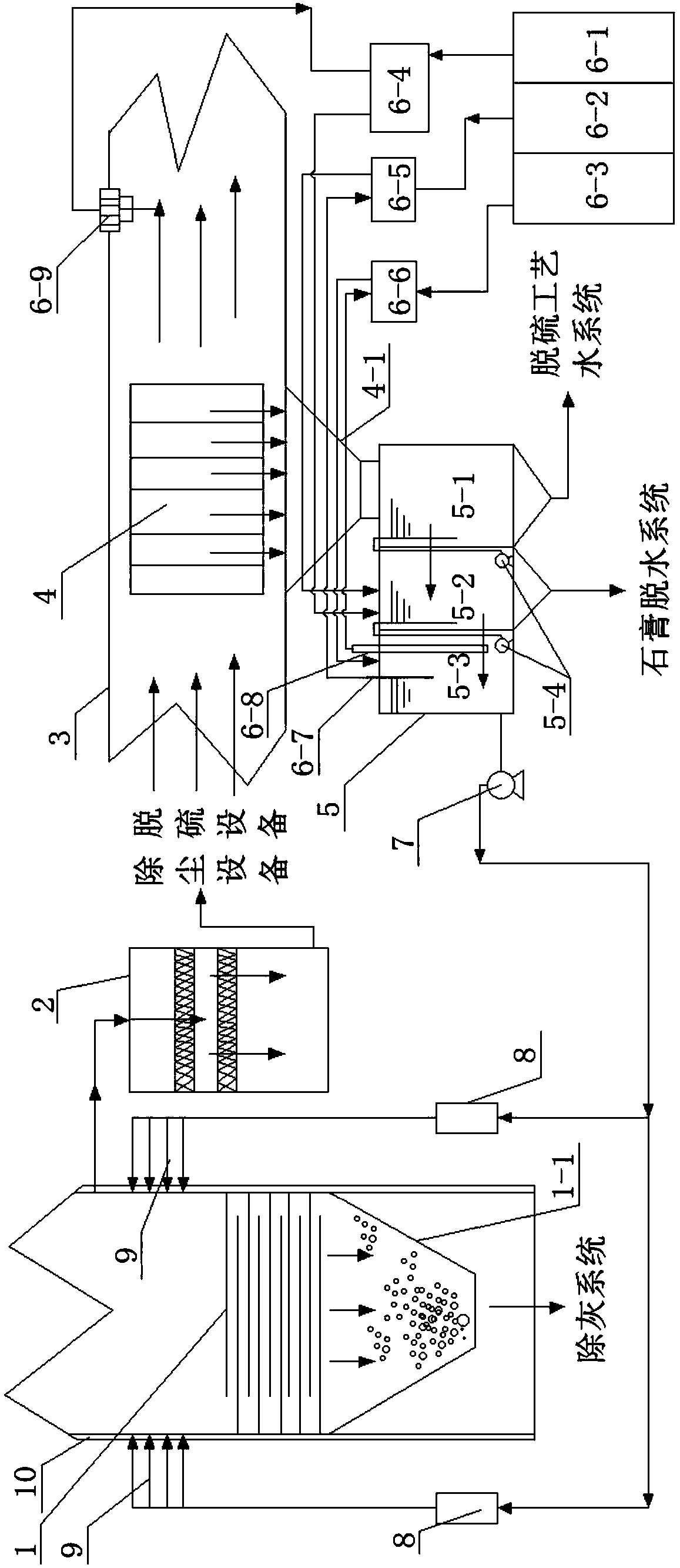

[0034] figure 1 It is a structural principle diagram of an embodiment of the present invention. As shown in the figure, a high-temperature flue gas mercury removal device includes a water-saving condenser 4, a triple water tank 5, a dosing system, an ultrasonic atomization system, and a water-saving condenser 4 is embedded and installed in the exhaust pipe 3, the water outlet of the water-saving condenser 4 is connected to the triple water tank 5, the triple water tank 5 is connected to the dosing system, the water outlet of the triple water tank 5 is connected to the ultrasonic atomization system, and the ultrasonic atomization system is set in the province In the boiler flue 10 above the coal heater 1, the flue gas passes through the economizer 1 and the ultrasonic atomization system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com