Flue gas desulfurization and mercury removal device and method

A flue gas and mercury removal technology, which is applied in the direction of separation methods, chemical instruments and methods, and mercury compounds, can solve the problems of high cost of flue gas desulfurization and mercury removal, achieve high desulfurization and mercury removal effects, simple devices, and improve costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

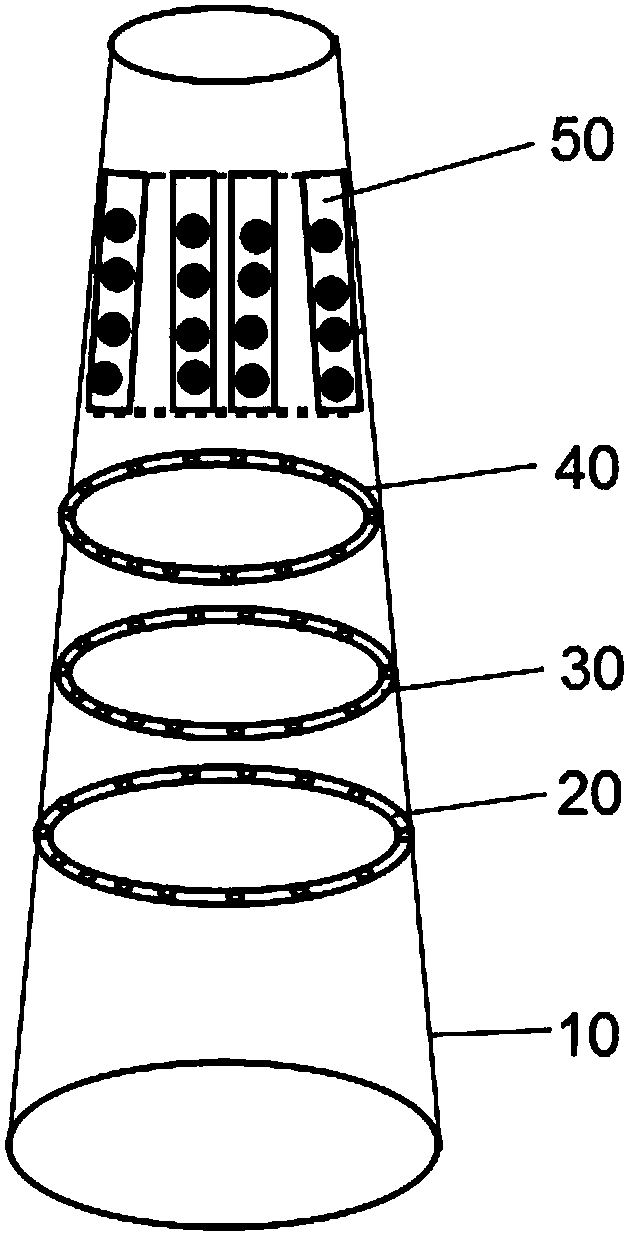

[0051] Taking the flue gas produced by a coal-to-liquid enterprise in Ningxia Hui Autonomous Region as the processing object, install an oxidation slurry spray device, a desulfurization slurry spray device, a hydrogen sulfide gas spray device and a bag filter in the chimney. The structure is as follows figure 1 As shown, where

[0052] The oxidizing slurry includes hypochlorous acid, sodium chloride, calcium bromide and water. The molar ratio of hypochlorous acid, sodium chloride and calcium bromide is 1:2:3, and the mass concentration of hypochlorous acid is 20%;

[0053] The desulfurization slurry includes calcium hydroxide, limestone and water, the weight ratio of calcium hydroxide to limestone is 3:2, and the mass concentration of calcium hydroxide is 20%;

[0054] The bag filter is provided with an adsorption packing layer of brominated activated carbon.

[0055] After stable operation, the average mercury removal rate of flue gas was 94.3%, and the average desulfurization rate w...

Embodiment 2

[0057] Taking the flue gas produced by a coal-to-liquid enterprise in Ningxia Hui Autonomous Region as the processing object, install an oxidation slurry spray device, a desulfurization slurry spray device, a hydrogen sulfide gas spray device and a bag filter in the chimney. The structure is as follows figure 1 As shown, where

[0058] The oxidizing slurry includes hypochlorous acid, sodium chloride, calcium bromide and water. The molar ratio of hypochlorous acid, sodium chloride and calcium bromide is 1:1.5:2.5, and the mass concentration of hypochlorous acid is 20%;

[0059] The desulfurization slurry includes calcium hydroxide, limestone and water, the weight ratio of calcium hydroxide to limestone is 2:1, and the mass concentration of calcium hydroxide is 20%;

[0060] The bag filter is provided with an adsorption packing layer of brominated activated carbon.

[0061] After stable operation, the average mercury removal rate of flue gas was 93.9%, and the average desulfurization ra...

Embodiment 3

[0063] Taking the flue gas produced by a coal-to-liquid enterprise in Ningxia Hui Autonomous Region as the processing object, install an oxidation slurry spray device, a desulfurization slurry spray device, a hydrogen sulfide gas spray device and a bag filter in the chimney. The structure is as follows figure 1 As shown, where

[0064] The oxidizing slurry includes hypochlorous acid, sodium chloride, calcium bromide and water. The molar ratio of hypochlorous acid, sodium chloride and calcium bromide is 1:2.5:3.5, and the mass concentration of hypochlorous acid is 20%;

[0065] The desulfurization slurry includes calcium hydroxide, limestone and water, the weight ratio of calcium hydroxide to limestone is 1:1, and the mass concentration of calcium hydroxide is 20%;

[0066] The bag filter is provided with an adsorption packing layer of brominated activated carbon.

[0067] After stable operation, the average mercury removal rate of flue gas was 92.5%, and the average desulfurization ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com