Upward flanging device for stamped pieces

A technology of stamping parts and components, which is applied in the field of flanging devices, can solve problems such as insufficient upturning force, insufficient installation surface area, and inability to install upturning inserts, etc., and achieves the effect of reasonable structural layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

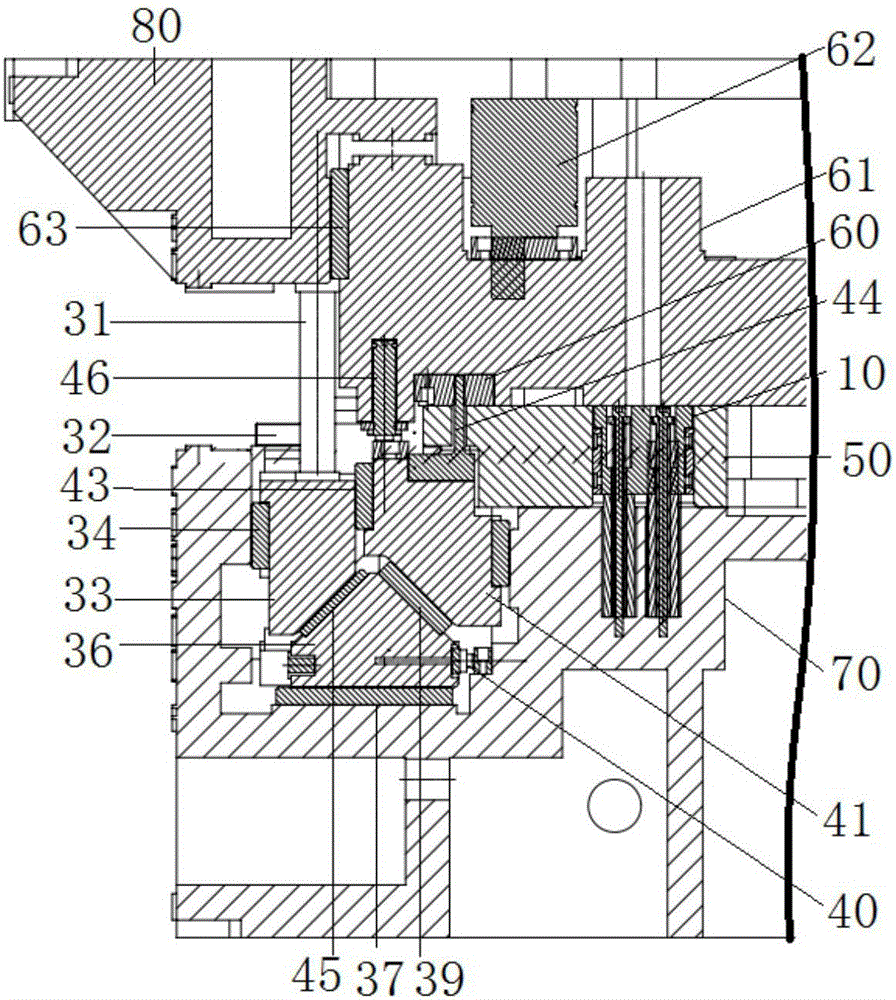

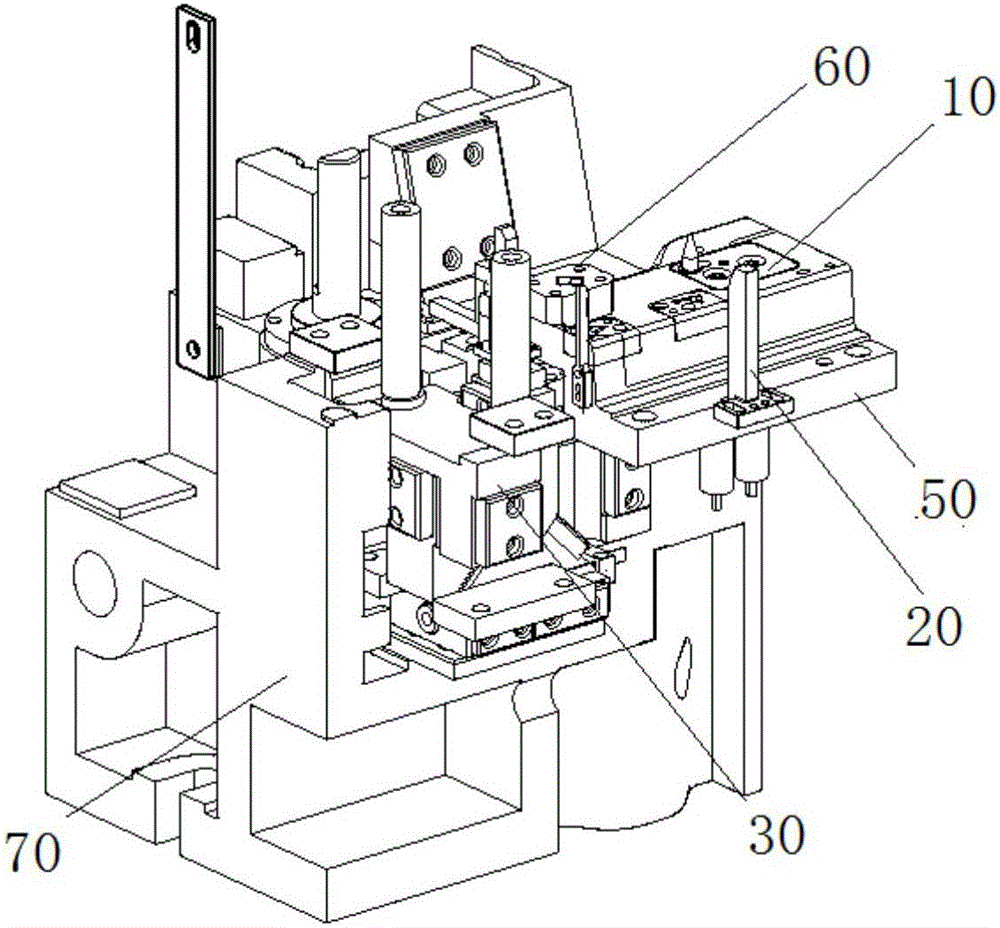

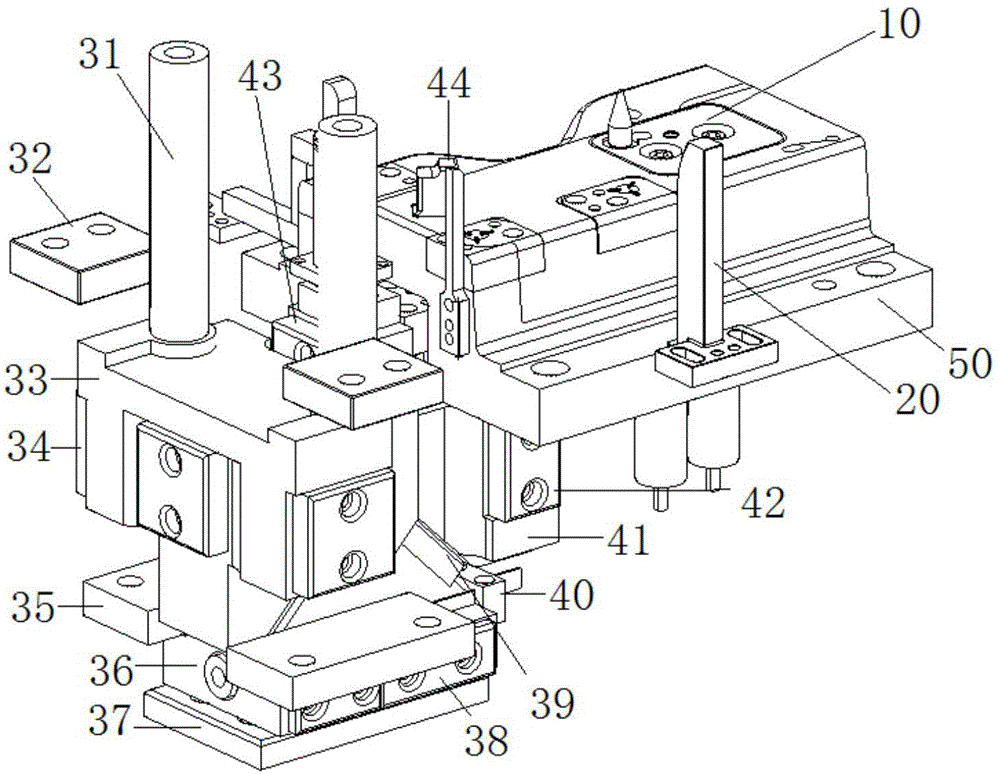

[0028] Embodiment 2 of the present invention: as Figure 1-Figure 4 As shown, a stamping part upper flanging device includes an upper mold base 80, a lower mold base 70, a pressing core body 61, an upturning mechanism 30 and a punch 50, and the pressing core body 61 is passed through a nitrogen cylinder The assembly 62 and the binder core guide element 63 are installed on the upper mold base 80, and the binder core guide element 63 is vertically arranged between the binder core body 61 and the upper mold base 80, Play the role of sliding. The turning-up mechanism 30 and the punch 50 are fixedly installed on the lower mold base 70, the turning-up mechanism 30 includes a drive slider 33, a pulley slider 36 and an upturning slider 41, and the slider slide The top of block 36 is the cone that section shape is triangular, and the bottom is cuboid, and the bottom of described driving slide block 33 and described turning over slide block 41 is all provided with the inclined-plane th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com