Aluminum alloy piece welding method

A welding method and aluminum alloy technology, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve problems such as weld cracks, reduce dust pollution, have good toughness, and improve repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

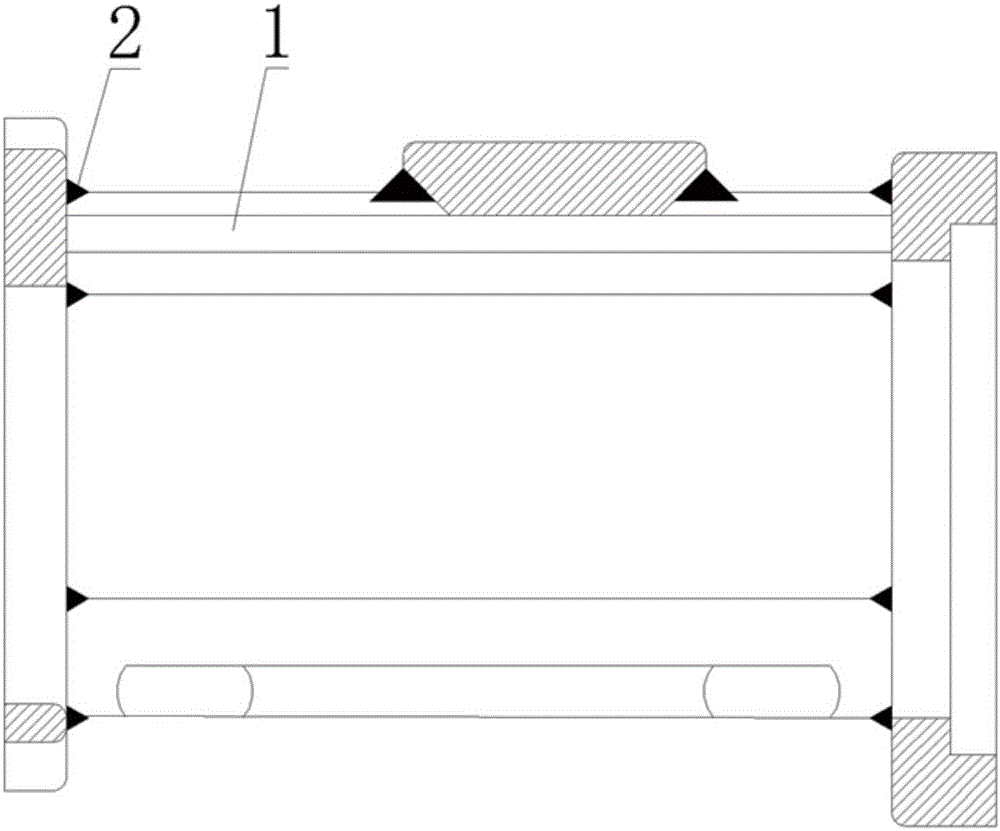

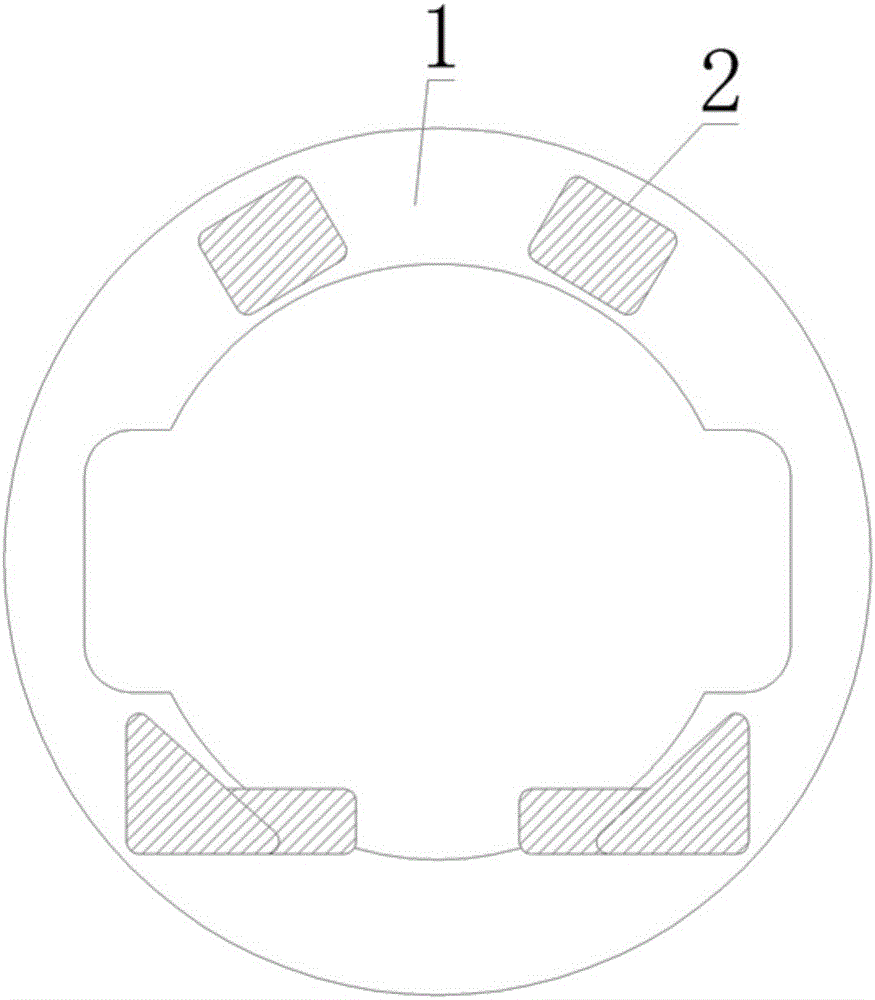

[0025] Embodiment of the welding method of aluminum alloy parts in the present invention: the welding method is a mixed welding method of dissimilar welding wires for key structural parts of aluminum alloys used in high-voltage electrical products, and is especially suitable for plate thicknesses ranging from 30 mm to 90 mm and welding angle heights exist High quality soldering between the 6061 boards. Taking the key structural parts of aluminum alloy used in high-voltage electrical appliances as an example, the mixed welding method of dissimilar welding wires includes the following steps:

[0026] 1) Clean the riveting tooling and check all the welding parts, use cleaning agent to clean the dust and oil on the weld and its 50mm range, and use a wire brush or thousand blades to clean the oxide film at the welding groove;

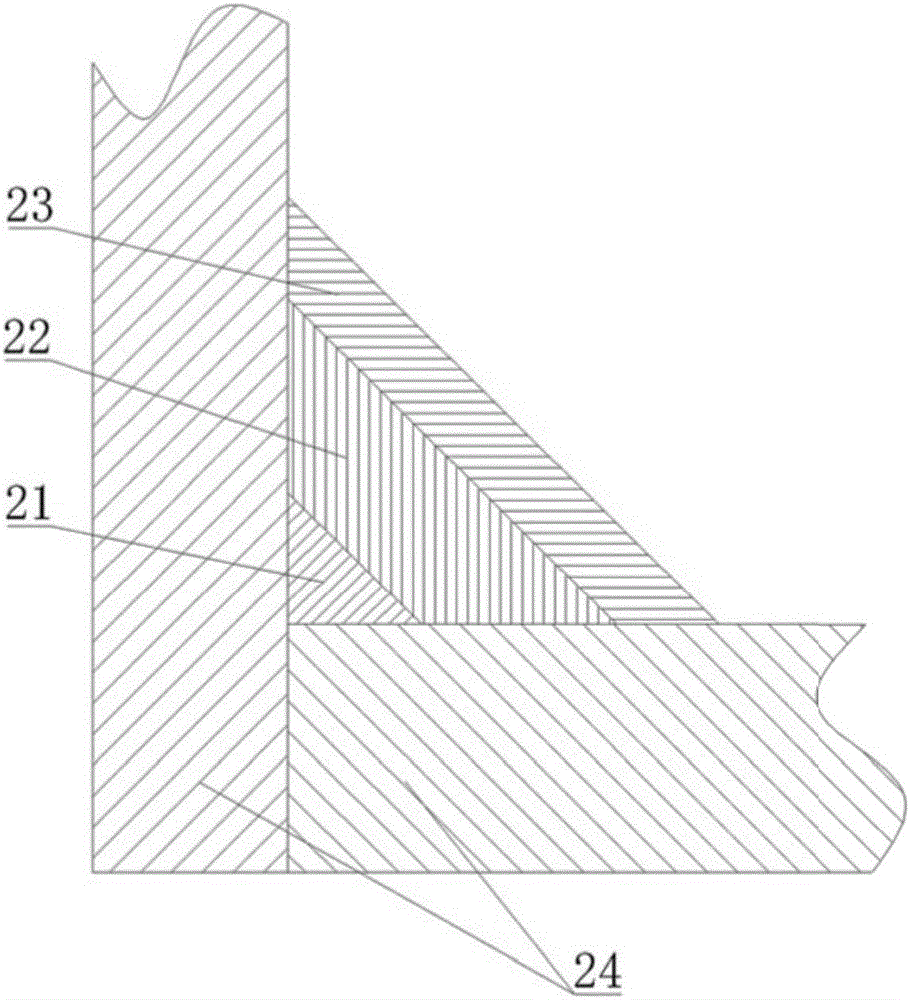

[0027] 2) riveting each welding sub-piece on the riveting tooling to obtain the base metal 24;

[0028] 3) Carry out horizontal welding on the base metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com