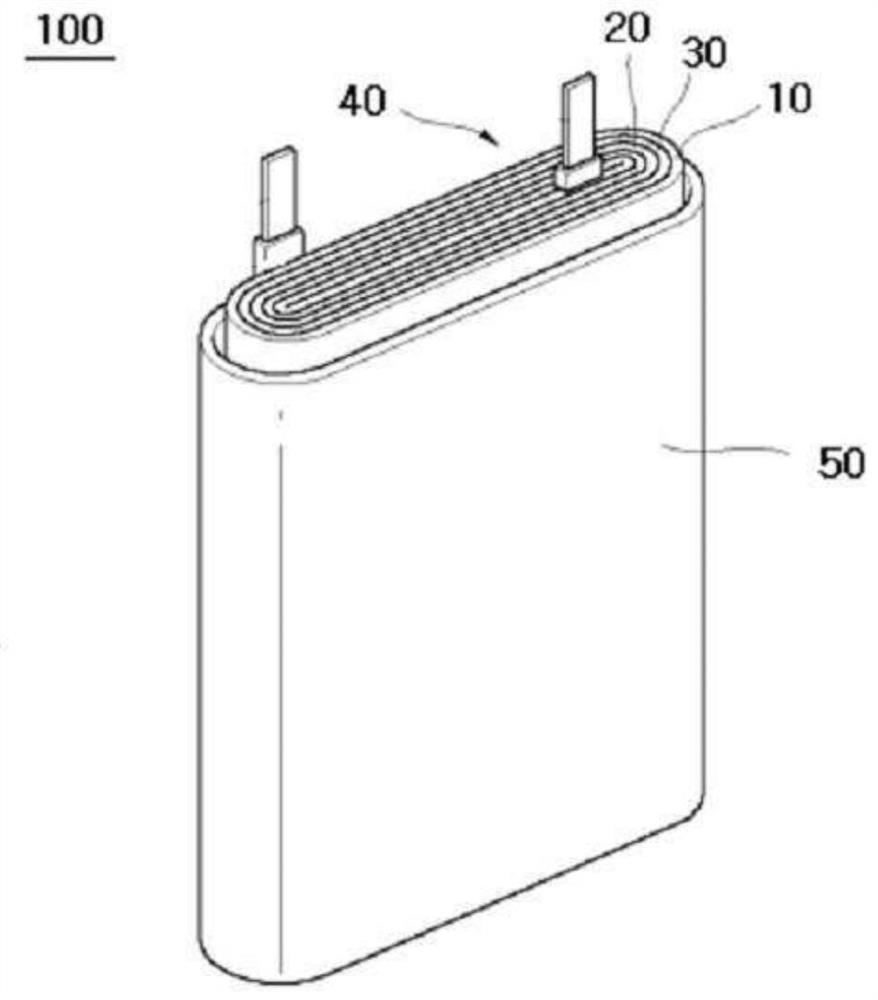

Electrochemical battery

An electrochemical and battery technology, applied in the field of manufacturing the separator and electrochemical battery, can solve problems such as thermal explosion, and achieve the effects of improving battery performance, high-efficiency charging/discharging characteristics, and avoiding performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0105] Preparation Example 1: Preparation of the First Solution

[0106] Mix 7% by weight of polyvinylidene fluoride homopolymer (Solvay 5120 (Solef 5120), Solvay Specialty Polymers (Solvay Specialty Polymers)) and 93% by weight of dimethylacetamide (DMAc, Dazhong Chemical and Metal Co., Ltd. company), followed by stirring at 40°C for 3 hours, thereby preparing the first solution.

preparation example 2

[0107] Preparation Example 2: Preparation of the Second Solution

[0108] 7% by weight of polyvinylidene fluoride copolymer (KF9300, Kureha Chemicals) and 93% by weight of dimethylacetamide (DMAc, Dazhong Chemical and Metal Co., Ltd.) were mixed, followed by stirring at 40°C for 3 hours, thus preparing a second solution.

preparation example 3

[0109] Preparation example 3: preparation of the third solution

[0110] A third solution was prepared by mixing 10% by weight of poly(methyl methacrylate) and 90% by weight of acetone, followed by stirring at 40°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com