Manufacturing method of fermented rose wine

A rose wine and fermented technology, which is applied in the field of fermented rose wine preparation, can solve the problems of red wine rose fragrance, small rose effect, and low efficacy, so as to speed up the ripening aging process, shorten the aging period, and improve the taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

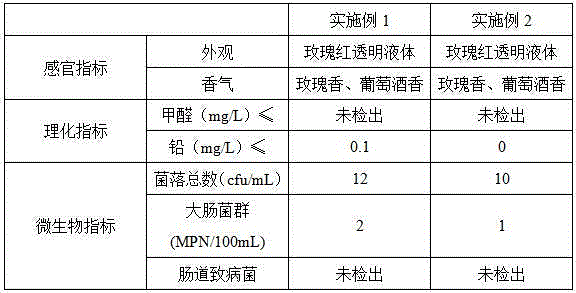

Examples

Embodiment 1

[0022] A preparation method for fermented rose wine, the method comprising the following steps:

[0023] a. Prepare rose syrup: crush 400kg of fresh double-petaled red roses, add 32kg of white granulated sugar, and stir to obtain rose syrup;

[0024] b. Fermentation: Rinse and dry 400kg of whole grapes and put them into a fermenter filled with rose syrup, ferment at 28°C for 18 days, filter, pass ozone into the filtrate for 15 minutes, and then oxidize the filtrate at 15-20 Ripening and aging for 3 months under the condition of ℃;

[0025] c. after ripening and aging, filter again, add 0.8kg propolis to the filtrate, add 1.5g citric acid per liter of filtrate, and obtain the fermented rose wine after sterilization, filtration and clarification.

[0026] The prepared rose wine tastes soft, mellow and harmonious, and after long-term drinking, it has the effects of regulating qi and relieving depression, promoting blood circulation and dispelling blood stasis, regulating menstru...

Embodiment 2

[0028] A preparation method for fermented rose wine, the method comprising the following steps:

[0029] a. Preparation of rose syrup: crush 400kg of fresh double-petaled red roses, add 24kg of white granulated sugar, and stir to obtain rose syrup;

[0030] b. Fermentation: Rinse and dry 320kg of whole grapes and put them into a fermenter filled with rose syrup, ferment at 25°C for 25 days, filter, pass through the filtrate to oxidize and sterilize for 10 minutes, and then sterilize the filtrate at 15- Ripening and aging for 3 months at 20°C;

[0031] c. after ripening and aging, filter again, add 2kg of propolis to the filtrate, add 1.8g of citric acid per liter of filtrate, sterilize, filter and clarify to obtain the fermented rose wine.

[0032] The prepared rose wine tastes soft, mellow and harmonious, and after long-term drinking, it has the effects of regulating qi and relieving depression, promoting blood circulation and dispelling blood stasis, regulating menstruation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com