Drying structure for copper wire subjected to annealing cooling treatment

An annealing and copper wire technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems affecting the performance of copper wires, oxidation of copper wires, etc., to achieve the effect of ensuring performance and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

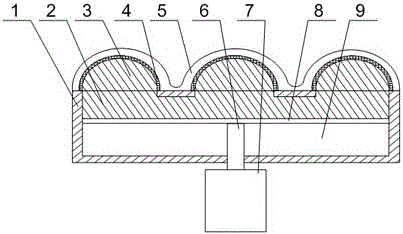

[0020] Such as figure 1 As shown, the present embodiment includes a box body 1, a plurality of through holes are opened above the box body 1, and a partition 8 and a cylinder 7 are also included, and the partition board 8 divides the inside of the box body 1 into a filling cavity and a hollow Cavity 9, the output end of the cylinder 7 is equipped with a connecting rod 6, the upper end of the connecting rod 6 moves through the bottom of the box body 1 and extends to connect with the bottom of the partition 8; the filling cavity is filled with sponge blocks 2, And the upper surface of the sponge block 2 protrudes outwards through the through hole to form the absorption part 3, and a plurality of sieve plates 4 for wrapping and covering the absorption part 3 are arranged on the box body 1, and among the plurality of sieve plates 4. The upper surface is bonded with a dehumidifying cloth 5. When in use, the box body 1 is filled with a sponge block 2, and the sponge block 2 protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com