Underground building exterior wall and envelop structure and construction method thereof

A technology for underground structures and enclosure structures, applied in building structures, infrastructure engineering, walls, etc., can solve problems such as leakage, poor waterproofing, inconsistent settlement, etc., achieve rational use of resources, reduce thickness, avoid The effect of even settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

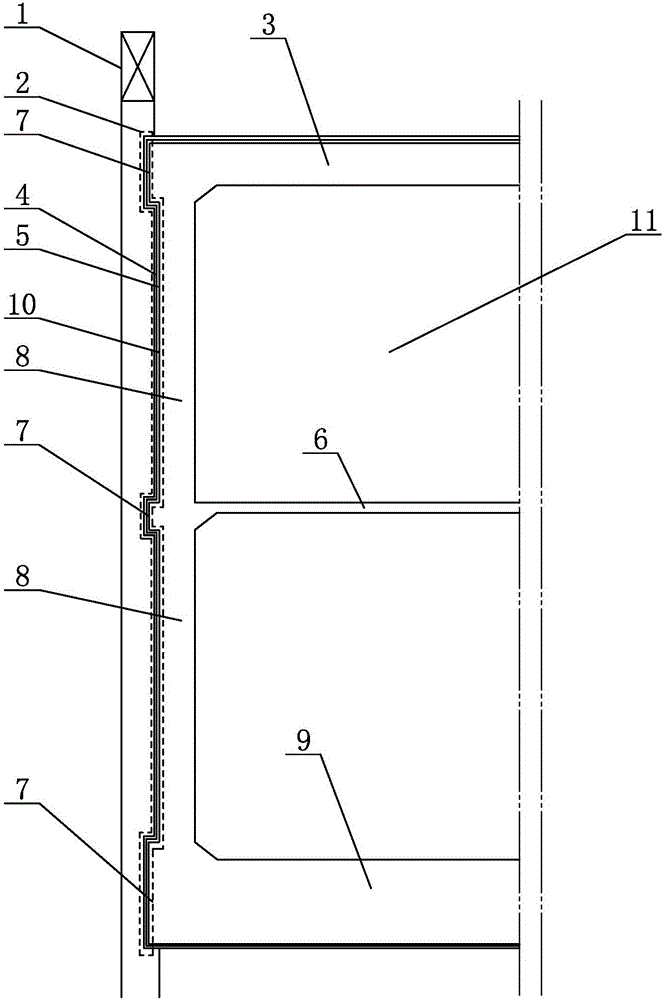

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, the exterior wall and enclosure structure of an underground structure described in this embodiment includes a bottom plate 3, a roof 9, a plurality of ground connecting walls 1, a plurality of intermediate plates 6, a plurality of force transmission plate strips 7, a plurality of The outer wall 8 and a plurality of force transmission plates 10, and a plurality of ground connecting walls 1 are sequentially connected end to end to form a frame body, and the frame body is arranged between the upper surface of the bottom plate 3 and the lower surface of the bottom plate 3, and the bottom plate 3, the top plate A ground connection wall 1 forms a closed space, and a plurality of intermediate plates 6 are arranged in parallel in the enclosed space from bottom to top, and a plurality of intermediate plates 6 divide the enclosed space into a plurality of space layers 11, and the edge of the bottom plate ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the outer wall of an underground structure described in this embodiment and the inner wall of the ground connection wall 1 of the enclosure structure and the flat layer 2 are sequentially provided with a flexible waterproof layer 4 and a waterproof protective layer 5 from outside to inside The upper surface of the main body top plate 8 is provided with a flexible waterproof layer 4 and a waterproof protective layer 5 successively, and the lower surface of the bottom plate 3 is sequentially provided with a flexible waterproof layer 4 and a waterproof protective layer 5 from bottom to top. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, the depth of inserting the edges of the main body top plate 9, middle plate 6, and bottom plate 3 of an underground structure outer wall and enclosure structure into the ground connecting wall 1 is 1 / 3 of the thickness of the ground connecting wall 1 ~1 / 2. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com