Pipe gallery installation infrastructure, comprehensive pipe gallery and installation and construction methods

A technology for installing foundation and comprehensive pipe gallery, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of poor settlement capacity, uneven resistance, long construction period, etc., and achieves low production cost, installation and construction operation. Simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the drawings and embodiments.

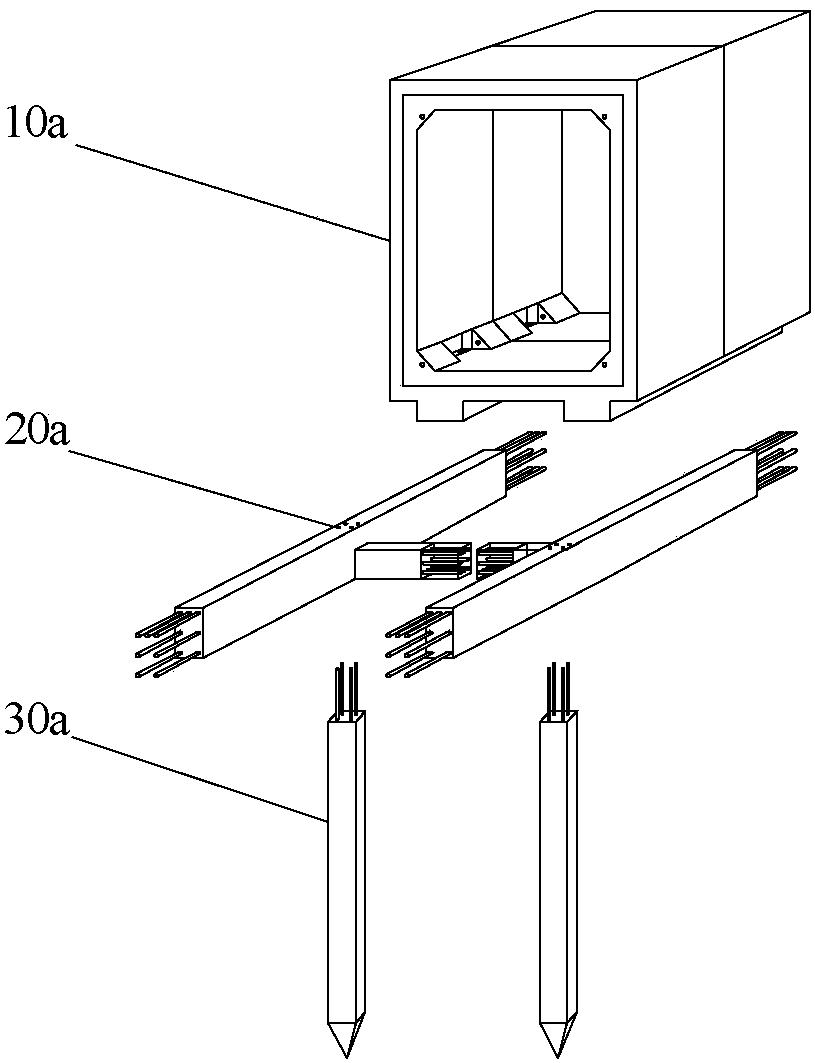

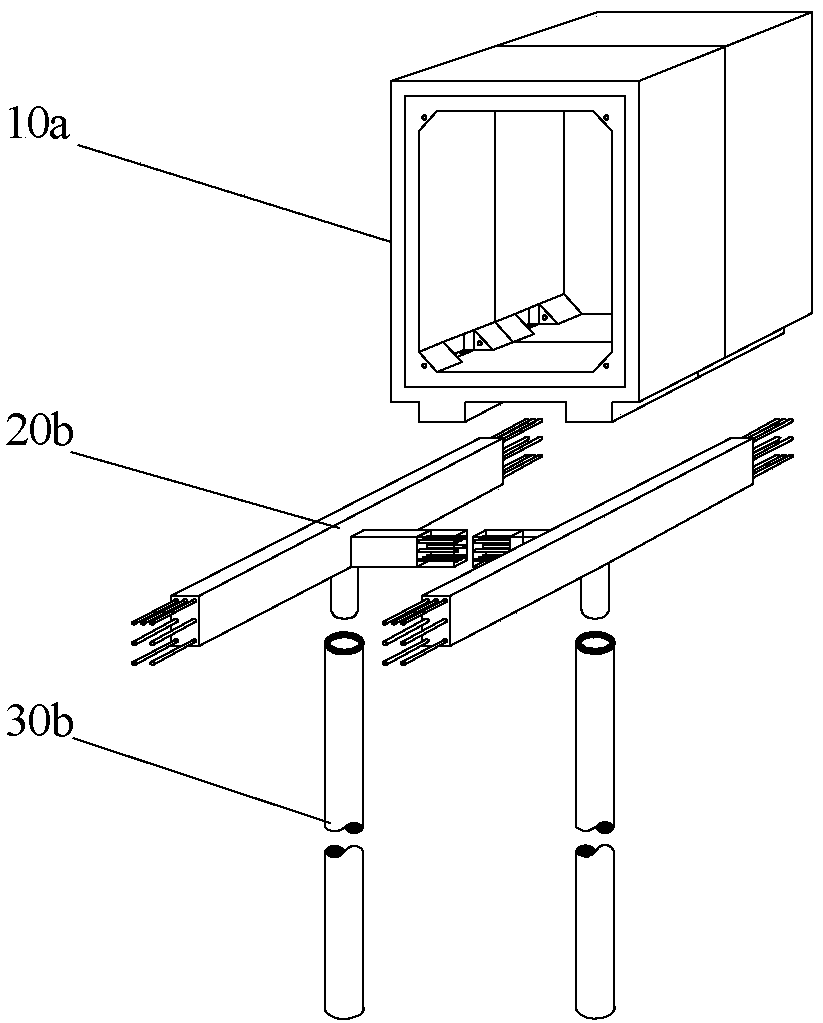

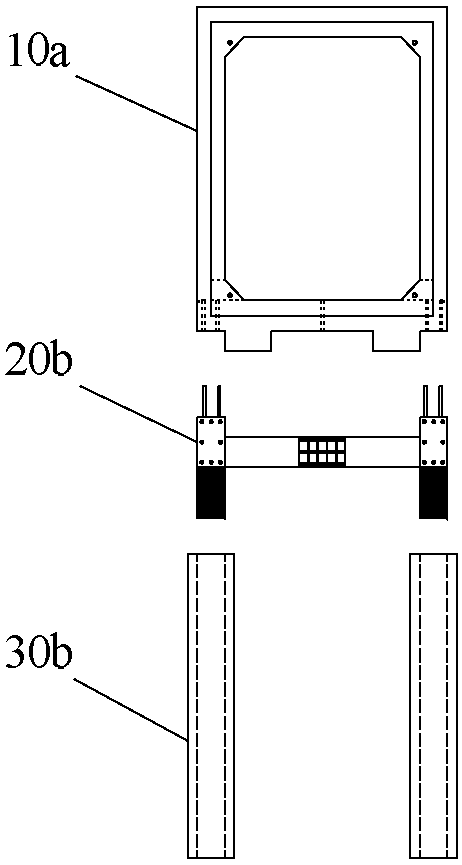

[0075] Such as Figure 1 to Figure 4 As shown, the pipe gallery installation base structure of the present invention includes frame beams 20a, 20b and precast piles 30a, 30b.

[0076] The sash beams 20a and 20b include main beams arranged in parallel and spaced apart and cross beams connecting adjacent main beams.

[0077] The precast piles 30a, 30b are vertically spaced at the bottom of the main beams of the frame beams 20a, 20b, and the center lines of the precast piles 30a, 30b are adapted to the vertical center plane of the main beam. The fit means that the centerline of the precast piles 30a, 30b can be located in the vertical center plane of the main beam, or near the vertical center plane of the main beam, to ensure that the pressure transmitted by the main beam to the precast piles 30a, 30b is located The center of the prefabricated piles 30a, 30b is located near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com