Spiral rotating shaft type local reverse circulation core drill bit

A reverse circulation and core drilling technology, which is used in earth-moving drilling, wellbore/well components, and original core extraction devices, etc., to achieve the effects of stable and reliable negative pressure, not easy to fall off, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

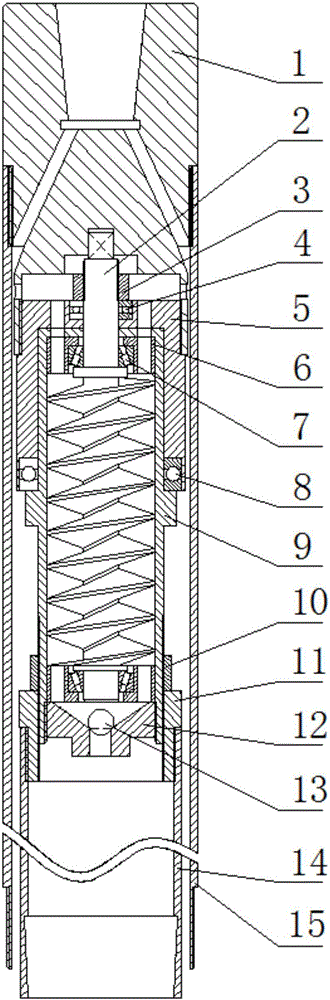

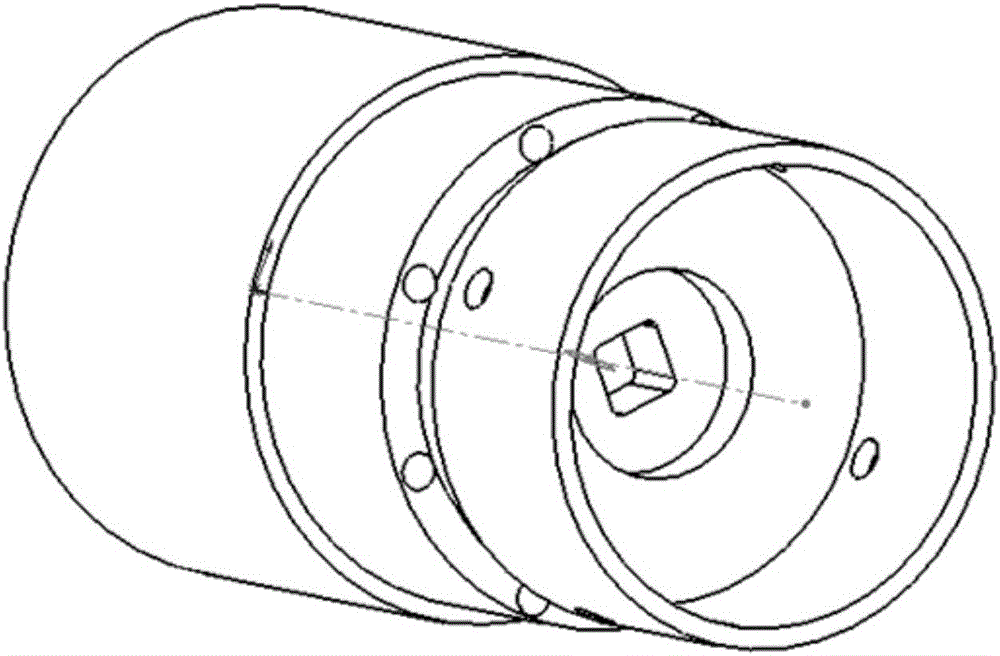

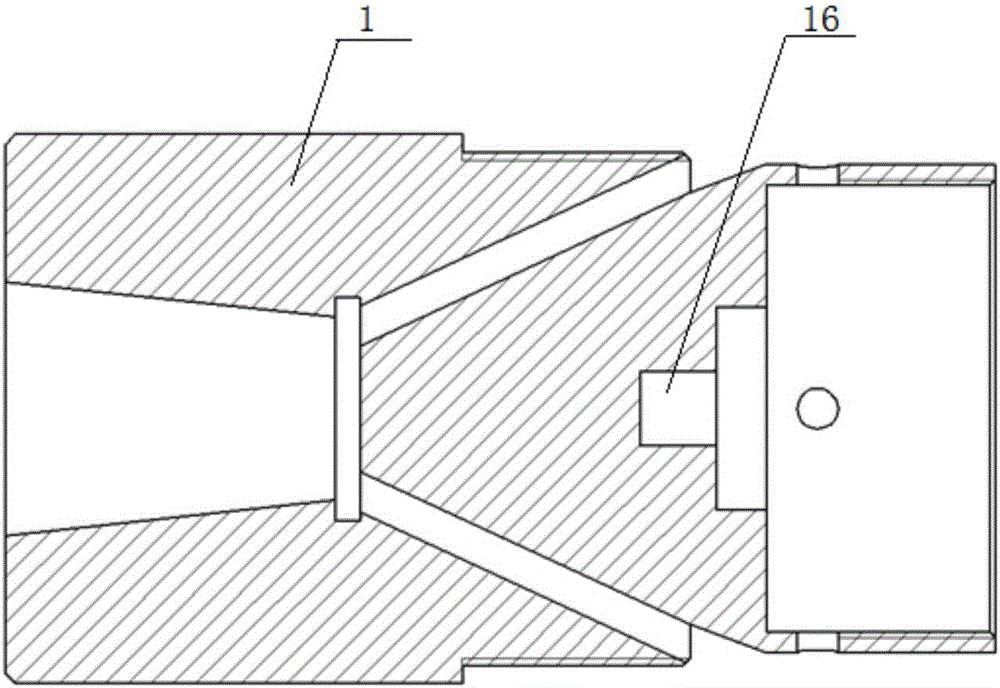

[0025] refer to Figure 1~Figure 4 As shown, the helical shaft type local reverse circulation core drilling tool of the present invention at least includes a joint 1, a transition element 5, a communication element 9, an inner pipe 14 and an outer pipe 15, and the joint 1 is divided into three parts from top to bottom. There are large outer diameter segments, intermediate segments, and small outer diameter segments with different outer diameters. The large outer diameter segments are provided with tapered threaded holes for connecting with drill pipes. The outer pipe 15 and the middle segment of the joint 1 The external thread connection, the transition element 5 is connected with the internal thread of the small outer diameter segment at the lower end of the joint 1, the transition element 5 is connected with the communication element 9, and the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com