Coal seam gas extraction pipe control device and control method

A pipeline control and coal seam gas technology, applied in the direction of gas discharge, safety devices, pipeline systems, etc., to overcome the time-consuming and labor-intensive wiring, wide application range, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

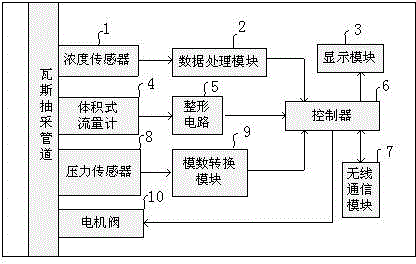

[0011] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 Shown: coal seam gas drainage pipeline control device, including gas concentration sensor 1, data processing module 2, display module 3, volumetric flowmeter 4, shaping circuit 5, controller 6, wireless communication module 7, pressure sensor 8, analog Number conversion module 9, motor valve 10.

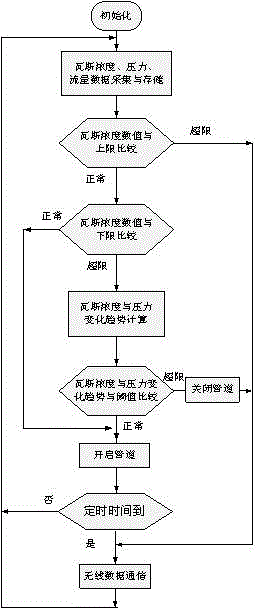

[0012] Principle of the present invention:

[0013] The gas concentration sensor 1 is connected with the controller 6 through the data processing module 2 to complete the concentration measurement. The volumetric flowmeter 4 is connected to the controller 6 through the shaping circuit 5 to complete the gas flow measurement. The pressure sensor 8 is connected to the controller 6 through an analog-to-digital converter 9 to complete pressure measurement. The display module 3 is directly connected with the controller 6 for displaying gas concentration, pressure and flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com