Natural gas liquefaction system and method based on plate heat exchanger and modular mixed refrigerant

A technology of mixed refrigerant and plate heat exchanger, which is applied in the direction of refrigeration and liquefaction, liquefaction, cold treatment separation, etc., can solve the problems of unfavorable equipment modularization, complicated process, and inappropriateness, so as to facilitate equipment modularization and simplify purification equipment , adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

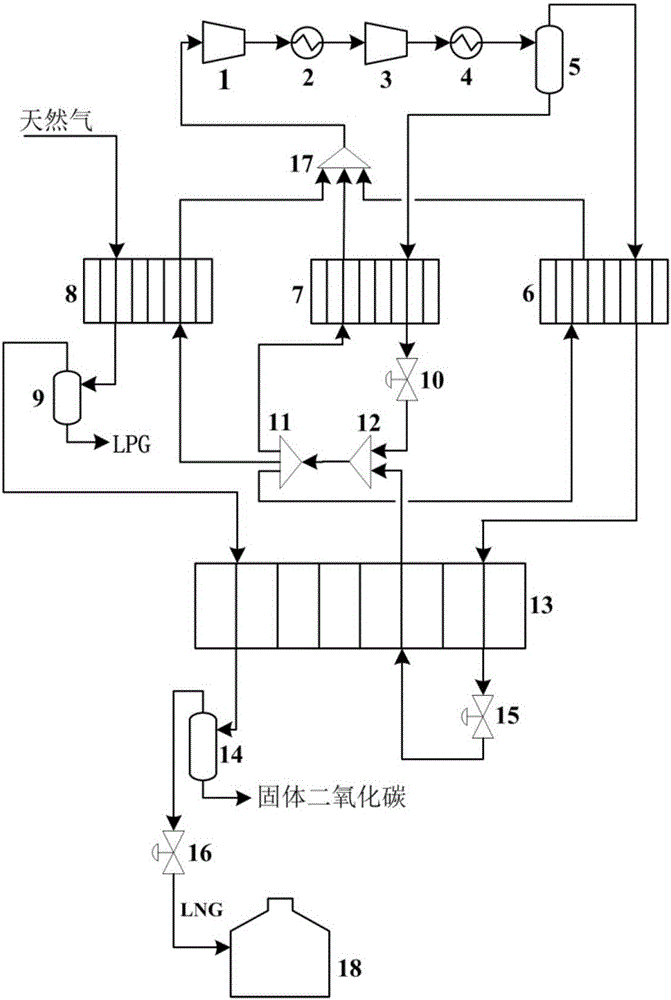

[0059] Natural gas molar composition 93% CH 4 +4%C 3 h 8 +2%N 2 +1%CO 2 , pressure 4.0MPa, temperature 40°C, flow rate 1kmol / h; mixed refrigerant flow rate 2.68kmol / h. The specific steps of the modular mixed refrigerant natural gas liquefaction process based on plate heat exchangers are as follows:

[0060] 1. The natural gas raw material is cooled to -40°C by the natural gas pre-cooling heat exchanger;

[0061] 2. The natural gas after step cooling enters the heavy hydrocarbon separator 9, and obtains heavy hydrocarbons from the bottom 2;

[0062] 3. The natural gas cryogenic heat exchanger 13 after removing heavy hydrocarbons in step 2 is cooled to -15°C;

[0063] 4. The natural gas obtained in step 3 enters the carbon dioxide separator 14, the liquefied natural gas flows out from the top of the carbon dioxide separator 14, and the solid carbon dioxide is separated from the bottom of the carbon dioxide separator 14;

[0064] 5. The liquefied natural gas after removing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com